Method for producing raw juice brown sugar

A raw juice and brown sugar technology, which is applied in sucrose production, sugar production, sugar juice purification, etc., can solve the problems of lower brown sugar quality, high refining degree, and low production capacity, and achieve stable product quality, high mechanization, and highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

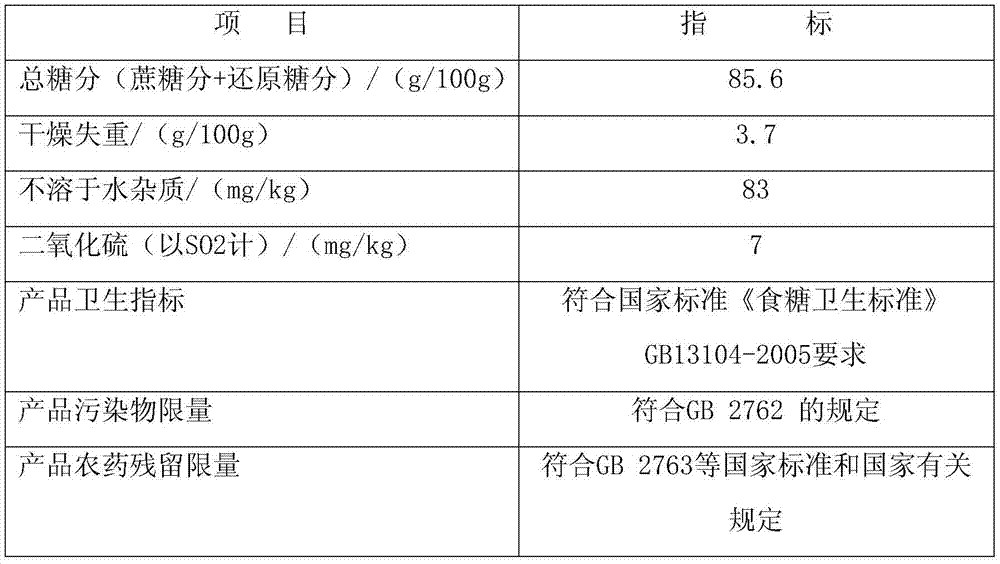

Embodiment 1

[0035] Embodiment 1 adopts the inventive method to produce raw juice brown sugar

[0036] 1. Sugarcane juice extraction: sugarcane is crushed into shreds and squeezed to obtain raw juice;

[0037] 2. Raw juice screening: transport the raw juice to an 80-200-mesh vibrating sieve, and filter with high-frequency vibration;

[0038] 3. Heating and floating: heat the filtered raw juice to 90-95°C for floating treatment;

[0039] 4. Disposal of floating objects: Use a rotary cleaning machine to clean the floating objects and send them to the extruder for extrusion.

[0040] 5. Whole juice filtration: The raw juice after the above treatment and the clear juice formed by extruding the foam extruder are sent to the filter press to filter the whole juice with polyester cloth to obtain the filtrate Ⅰ.

[0041] 6. Precipitation treatment: Transfer the filtrate Ⅰ to the sedimentation tank, let it stand still, and settle for 2 to 3 hours to remove fine mud impurities.

[0042] 7. Evapora...

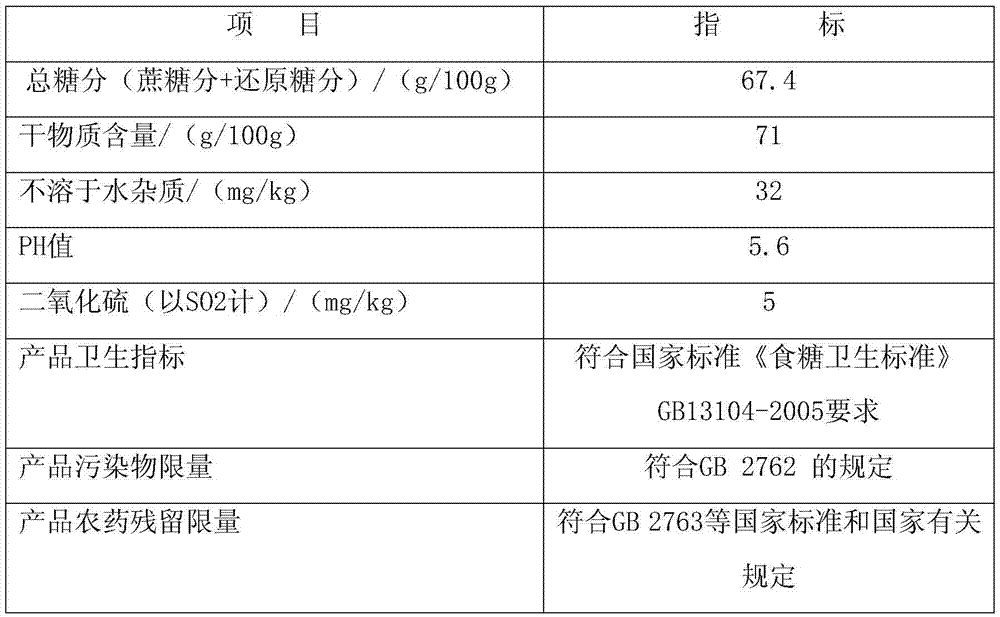

Embodiment 2

[0051] Embodiment 2 adopts the inventive method to produce raw juice brown sugar

[0052] 1. Sugarcane juice extraction: sugarcane is crushed into shreds and squeezed to obtain raw juice;

[0053] 2. Raw juice screening: transport the raw juice to an 80-200-mesh vibrating sieve, and filter with high-frequency vibration;

[0054] 3. Heating and floating: heat the filtered raw juice to 90-95°C for floating treatment;

[0055] 4. Disposal of floating objects: Use a rotary cleaning machine to clean the floating objects and send them to the extruder for extrusion.

[0056] 5. Whole juice filtration: The raw juice after the above treatment and the clear juice formed by extruding the foam extruder are sent to the filter press to filter the whole juice with polyester cloth to obtain the filtrate Ⅰ.

[0057] 6. Precipitation treatment: Transfer the filtrate Ⅰ to the sedimentation tank, let it stand still, and settle for 2 to 3 hours to remove fine mud impurities.

[0058] 7. Evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com