Caustic sulfite process caramel color production technology

A caustic sulfite, production process technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., to achieve the effect of preventing excessive catalysis, high safety, and reducing the amount of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

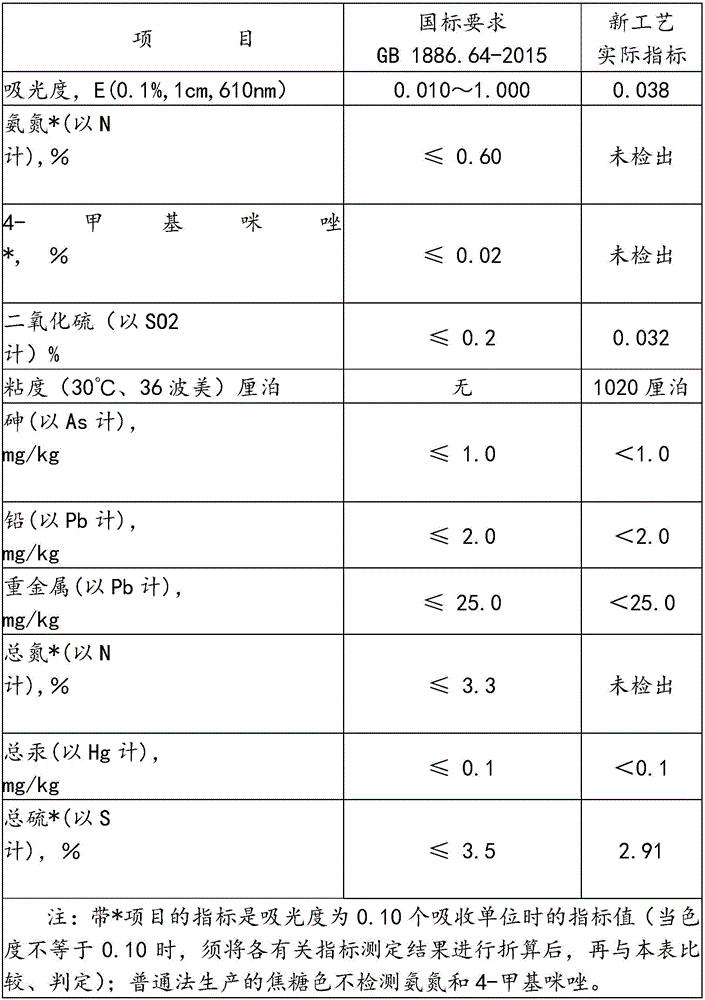

[0044] Production of 36Be, 10000EBC caustic acid salt method caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are both the measurement indicators of caramel color).

[0045]A kind of caustic sulfite method caramel color production process, comprises the following steps:

[0046] 1), raw material metering and concentration: pump maltose (the amount of dry matter is 6000Kg, DE value is 42%) into the reaction tank, and the raw material is concentrated to 65% on a dry basis in the reaction tank;

[0047] DE value refers to the mass percentage of reducing sugar (calculated as glucose) in dry matter;

[0048] 2), preparation of catalyst: take by weighing 300kg (5% of the amount of maltose dry matter) low sodium sulfite, be divided into 3 equal parts, every equal part 100Kg, set aside, take by weighing 18kg (0.3% of the amount of maltose dry matter) hydrogen Sodium oxide, divided into 3 equal parts, 6...

Embodiment 2

[0060] Production of 36Be, 30000EBC caustic acid salt method caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are both measurement indicators of caramel color).

[0061] A kind of caustic sulfite method caramel color production process, comprises the following steps:

[0062] 1), raw material metering concentration: pump fructose and glucose into the reaction tank at a ratio of 1:1 (the amount of dry matter is 6000Kg, and the DE value is 97%), and the raw material is concentrated in the reaction tank until the dry basis is 85 %;

[0063] DE value refers to the mass percentage of reducing sugar (calculated as glucose) in dry matter;

[0064] 2), preparation of catalyst: take by weighing 1800kg (30% of the amount of raw material dry matter) potassium pyrosulfite and sodium pyrosulfite (wherein potassium pyrosulfite 900Kg), be divided into 10 equal parts, every equal part 180Kg, spare, weigh Get ...

Embodiment 3

[0075] Production of 36Be, 20000EBC caustic acid salt method caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are both measurement indicators of caramel color).

[0076] A kind of caustic sulfite method caramel color production process, comprises the following steps:

[0077] 1), Raw material metering and concentration: pump molasses, xylose and sucrose into the reaction tank according to the ratio of 1:1:1 (the amount of dry matter is 6000Kg, and the DE value is 60%), and the raw materials are concentrated to dryness in the reaction tank. 75% basis;

[0078] DE value refers to the mass percentage of reducing sugar (calculated as glucose) in dry matter;

[0079] 2), the preparation of catalyst: take by weighing 900 kg (15% of the amount of dry matter of raw material)) sodium bisulfite, be divided into 8 equal parts, every equal part 112.5Kg, standby, take by weighing 900 kg (15% of dry matter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com