Method for producing powder caramel color through combination of spiral conveyer and extruder

A screw conveyor and powder caramel technology, applied in chemical instruments and methods, organic dyes, azo dyes, etc., can solve problems such as low production efficiency, difficult operation, and poor product quality, and achieve high production efficiency and high product quality Good, simple method and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

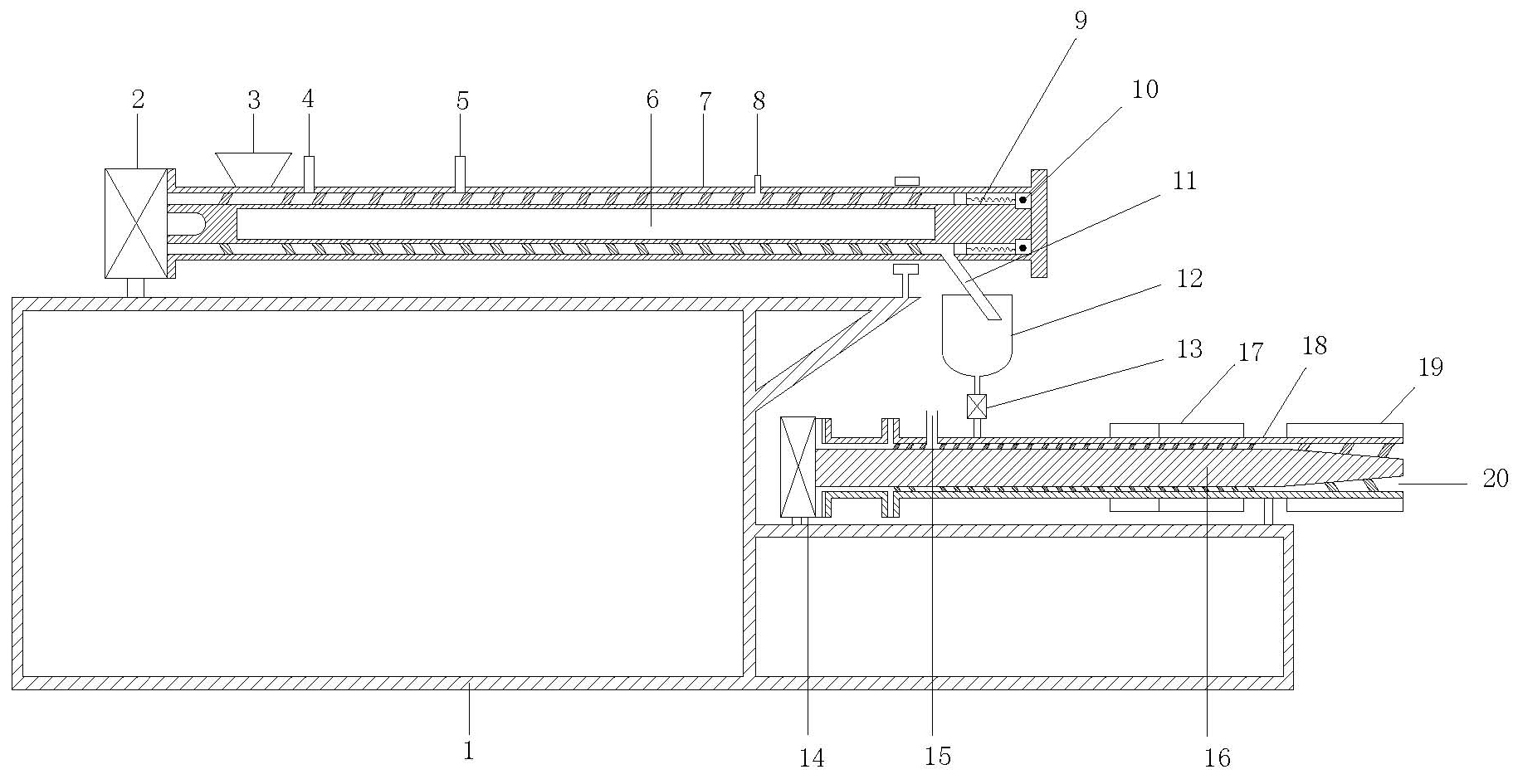

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

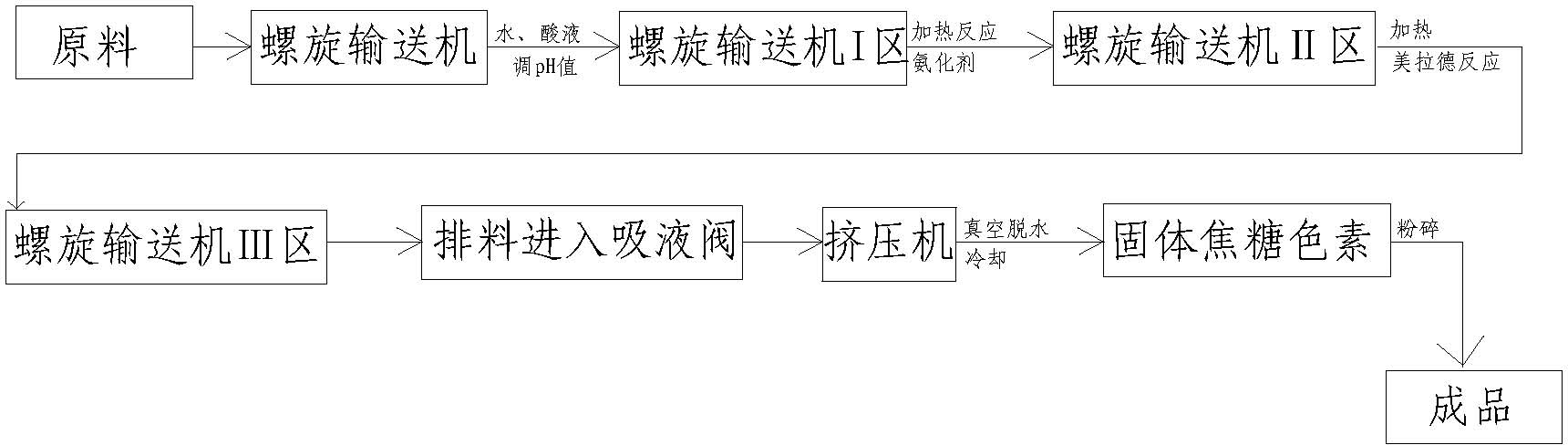

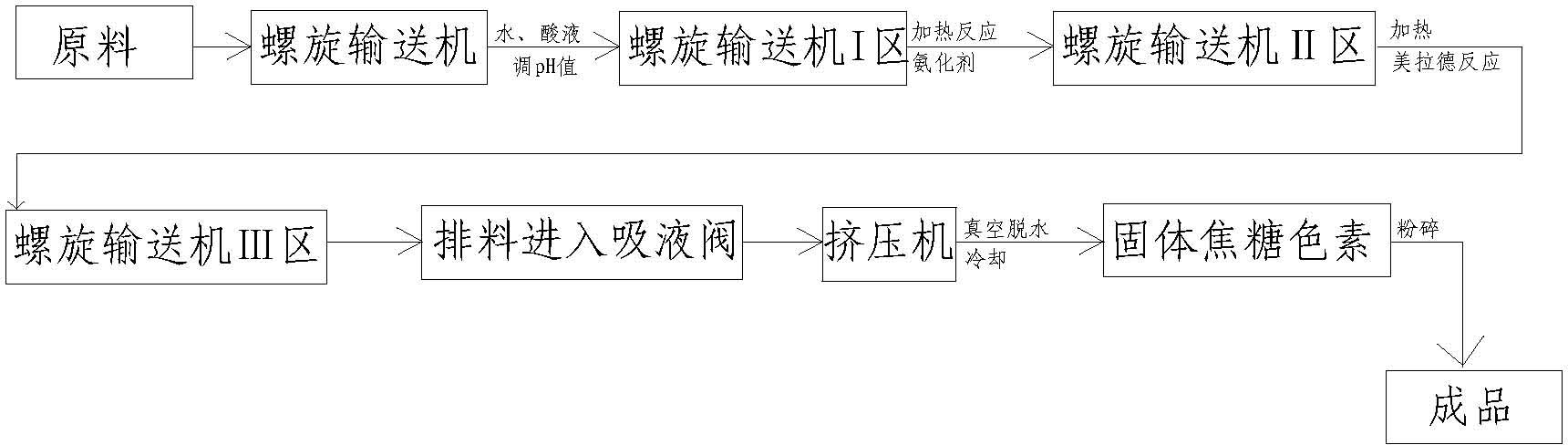

[0011] Depend on figure 1 , 2 Shown, the present invention is implemented by the following steps:

[0012] 1. Feed material, adjust pH value: Start the first speed-regulating motor (2) to drive the screw rod (6) to rotate, and the raw material glucose or sucrose enters the I area of the screw conveyor from the feed port (3) of the screw conveyor. , the acid liquid and water are poured into zone I of the screw conveyor through the interface (4) by the metering pump, mixed with the raw material glucose or sucrose, the pH value is adjusted to 1.5-4.5 by the acid liquid, and the amount of water added is the raw material glucose or sucrose 5-25% by weight; the acid solution is a kind of sulfuric acid, hydrochloric acid, phosphoric acid or citric acid;

[0013] 2. Saccharification reaction: heat to 190°C, and carry out preliminar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com