Low-temperature baking cake and manufacturing method thereof

A technology of low-temperature baking and production method, applied in baking, baked food, dough processing and other directions, can solve the problems of non-conformity, starch aging, incomplete starch gelatinization, etc., and achieve the effect of high moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

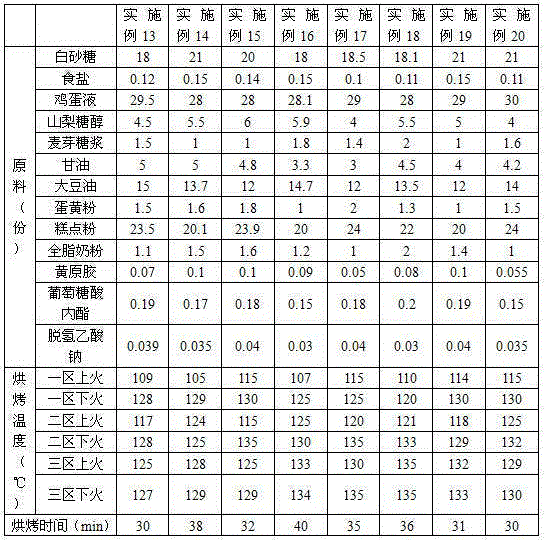

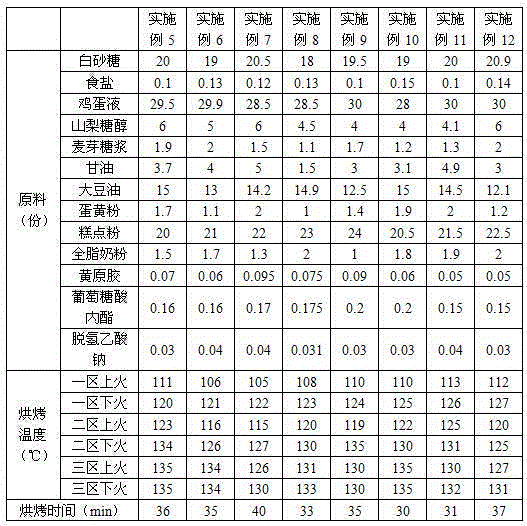

Examples

Embodiment 1

[0018] A low-temperature baked cake prepared from the following raw materials in parts by weight: 18-21 parts of white granulated sugar, 0.1-0.15 parts of table salt, 28-30 parts of egg liquid, 4-6 parts of sorbitol, and 1-2 parts of maltose syrup 3~5 parts of glycerin, 12~15 parts of soybean oil, 1~2 parts of egg yolk powder, 20~24 parts of pastry flour, 1~2 parts of whole milk powder, 0.05~0.1 parts of xanthan gum, 0.18~0.24 parts of preservatives parts; the preservative consists of 0.15~0.2 parts of gluconolactone and 0.03~0.04 parts of sodium dehydroacetate.

[0019] Among them, white granulated sugar, egg liquid, and pastry powder are the main raw materials of the cake structure. White granulated sugar is also the main sweetener. Egg liquid can also supplement protein, increase color and nutrition, salt adjusts taste, sorbitol and malt syrup replace part of sugar, maltose The pulp is also the main humectant, so that the cake will not produce Maillard reaction, and the egg...

Embodiment 2

[0028] A low-temperature baking cake prepared from the following raw materials in parts by weight: 20 parts of white granulated sugar, 0.1 part of salt, 30 parts of egg liquid, 4 parts of sorbitol, 1 part of malt syrup, 4 parts of glycerin, and 14 parts of soybean oil , 1 part of egg yolk powder, 23 parts of pastry powder, 2 parts of whole milk powder, 0.05 part of xanthan gum, 0.15 part of gluconolactone and 0.03 part of sodium dehydroacetate.

[0029] The preparation method of the above-mentioned low-temperature baking cake comprises the following steps:

[0030] (1) Ingredients: White sugar, salt, egg yolk powder, sodium dehydroacetate, xanthan gum, gluconolactone are mixed together and stirred evenly, egg liquid is separately prepared, soybean oil is separately prepared, pastry powder is separately prepared, and sorbet Sugar alcohol, malt syrup, and glycerin are configured together;

[0031] (2) Slurry production: Use Youyang Whisk for slurry production; ①White sugar, sal...

Embodiment 3

[0036] A low-temperature baking cake prepared from the following raw materials in parts by weight: 18 parts of white granulated sugar, 0.15 parts of table salt, 29 parts of egg liquid, 5 parts of sorbitol, 1 part of malt syrup, 5 parts of glycerin, and 14 parts of soybean oil , 2 parts of egg yolk powder, 24 parts of pastry powder, 1 part of whole milk powder, 0.06 part of xanthan gum, 0.16 part of gluconolactone and 0.03 part of sodium dehydroacetate.

[0037] The preparation method of the above-mentioned low-temperature baking cake comprises the following steps:

[0038] (1) Ingredients: White sugar, salt, egg yolk powder, sodium dehydroacetate, xanthan gum, gluconolactone are mixed together and stirred evenly, egg liquid is separately prepared, soybean oil is separately prepared, pastry powder is separately prepared, and sorbet Sugar alcohol, malt syrup, and glycerin are configured together;

[0039](2) Slurry production: Use Youyang Whisk for slurry production; ①White sug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com