Composite additive for improving physical moisture retention property of reconstituted tobacco

A compound additive and reconstituted tobacco leaf technology, applied in tobacco, food science, tobacco preparation, etc., can solve the problems of irritating and spicy taste, unfavorable taste of tobacco, and reduce water loss, etc., to achieve flexible use and heat stability , the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

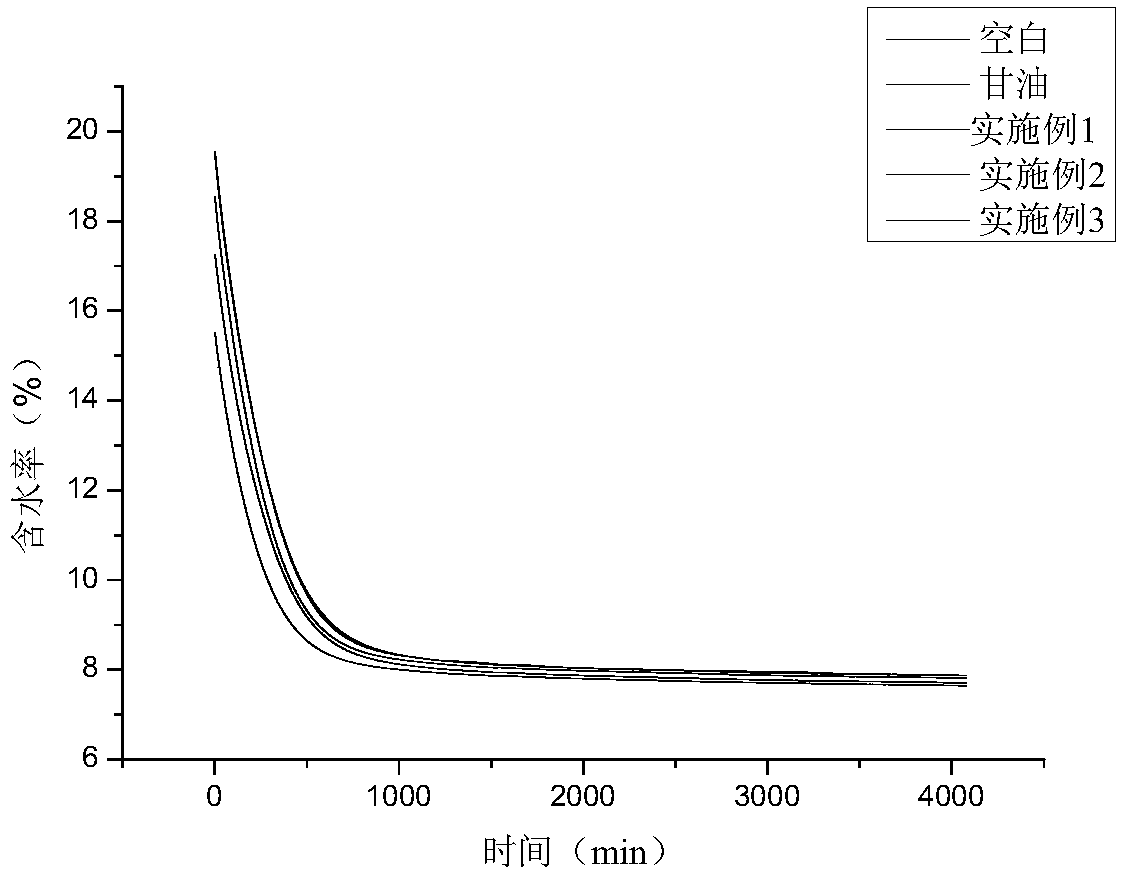

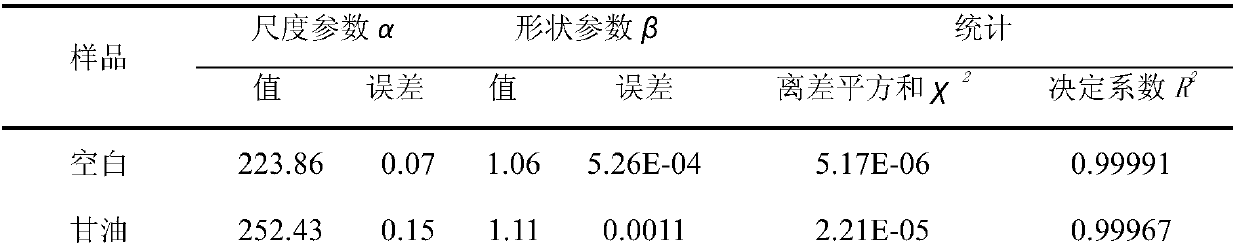

Embodiment 1

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto. Embodiment 1: The composition and mass percent of this composite additive are: polyethylene glycol (200) 10%, propylene glycol 3%, flue-cured tobacco extract 3%, caramelization reaction product (glucose is raw material) 3%, Maillard Product (glucose and proline reaction product) 3%, water 78%. The mass fraction of the reconstituted tobacco leaves is 0.05% and sprayed on the reconstituted tobacco leaves together with the coating liquid.

Embodiment 2

[0020] Embodiment 2: The composition and mass percent of this composite additive are: polyethylene glycol (900) 6%, propylene glycol 4%, flue-cured tobacco extract 2%, caramelization reaction product (glucose is raw material) 1%, Maillard Product (glucose and proline reaction product) 3%, water 84%. The mass fraction of the reconstituted tobacco leaves is 0.1% and sprayed on the reconstituted tobacco leaves together with the coating liquid.

Embodiment 3

[0021] Embodiment 3: The composition and mass percent of this composite additive are: polyethylene glycol (600) 8%, propylene glycol 3%, oriental tobacco tobacco extract 2%, caramelization reaction product (glucose is raw material) 2%, Merat German product (glucose and proline reaction product) 2%, water 83%. The mass fraction of the reconstituted tobacco leaves is 0.1% and sprayed on the reconstituted tobacco leaves together with the coating liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com