Preparation method of caramel pigment

A technology of caramel pigment and caramelization reaction, applied in chemical instruments and methods, functions of food ingredients, azo dyes, etc., can solve the problems of low color yield and high red pigment index, achieve low reaction temperature and simple operation , the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

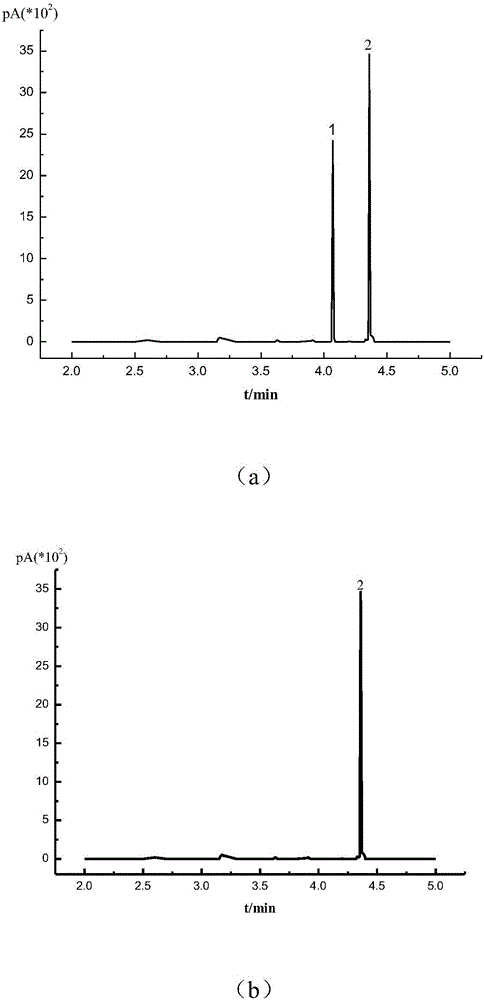

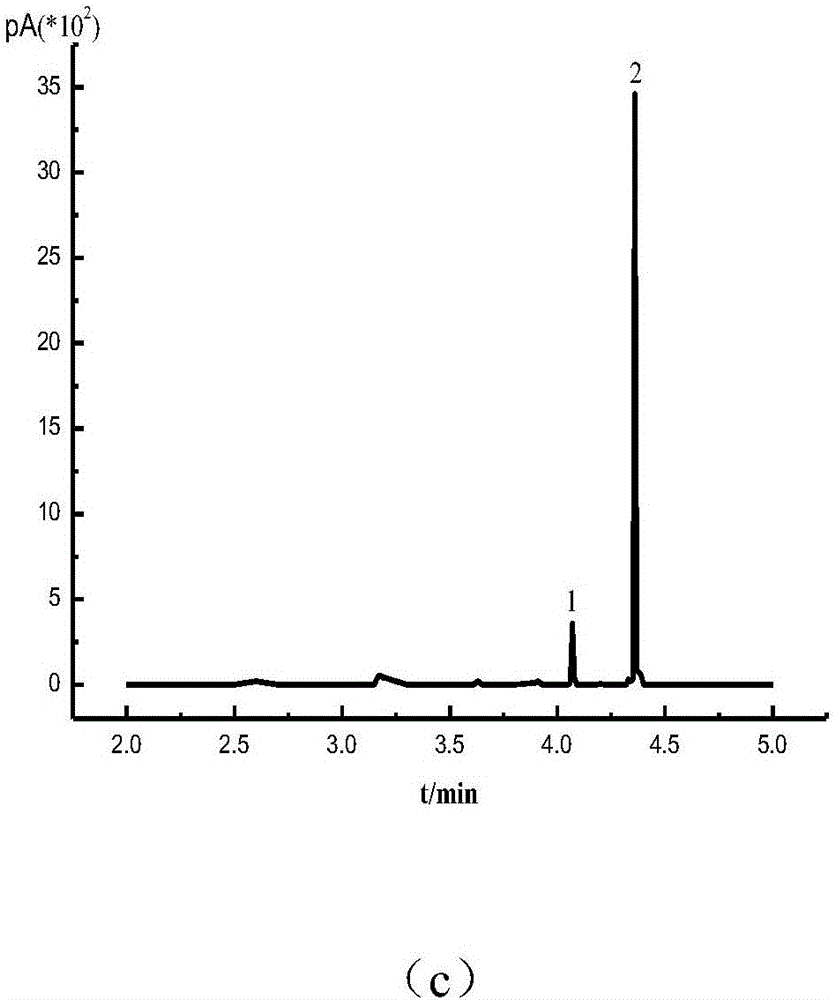

Image

Examples

Embodiment 1

[0034] A preparation method of caramel coloring, comprising the following steps:

[0035] 1) Primary reaction of caramelization reaction:

[0036] While stirring, add white sugar to a three-necked flask with stirring, reflux, and a thermometer, use an oil bath as the heating medium, and control the temperature of the oil bath to 200°C. When the temperature of the reaction system is 165°C, the white sugar begins to melt. When the temperature rises When the temperature is 185°C, the white granulated sugar is completely melted. As time goes on, the system temperature rises to 198°C. Condensate appears in the cooling pipe, and the system temperature drops to 160°C at a rate of 1.5°C / min. At this time, the temperature is basically stable. Between 160-170°C, react at this temperature for 2h.

[0037] 2) Add alkali to remove the acid produced in the caramelization process and promote the caramelization reaction

[0038] Slowly add 15 mL of 10% Na to the reaction system at a rate of...

Embodiment 2

[0042] A preparation method of caramel coloring, comprising the following steps:

[0043] 1) Primary reaction of caramelization reaction:

[0044] While stirring, add white sugar to a three-necked flask with stirring, reflux, and a thermometer, use an oil bath as the heating medium, and control the temperature of the oil bath to 198°C. When the temperature of the reaction system is 164°C, the white sugar begins to melt. When the temperature rises When the temperature is 185°C, the white granulated sugar is completely melted. As time goes on, the system temperature rises to 197°C, condensate appears in the cooling pipe, and the system temperature drops to 160°C at a rate of 1-2°C / min. At this time, the temperature It is basically stable at 160-170°C, and reacts at this temperature for 2.5h.

[0045] 2) Neutralize with alkali to promote the formation of caramel pigment

[0046] Slowly add 12 mL of 12% Na to the reaction system at a rate of 0.5 drops / s while stirring. 2 CO 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com