Anti-browning fruit-vegetable preservative and preparation method thereof

A fruit and vegetable preservative and anti-browning technology, which can be applied in the preservation of fruits and vegetables, food preservation, preservation of food ingredients as anti-microbials, etc., can solve the problems of reducing nutritional value, affecting product sensory quality, reducing commodity value, etc., and achieving curative effect. Significant, prevent the formation of the body, eliminate the effect of melanin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

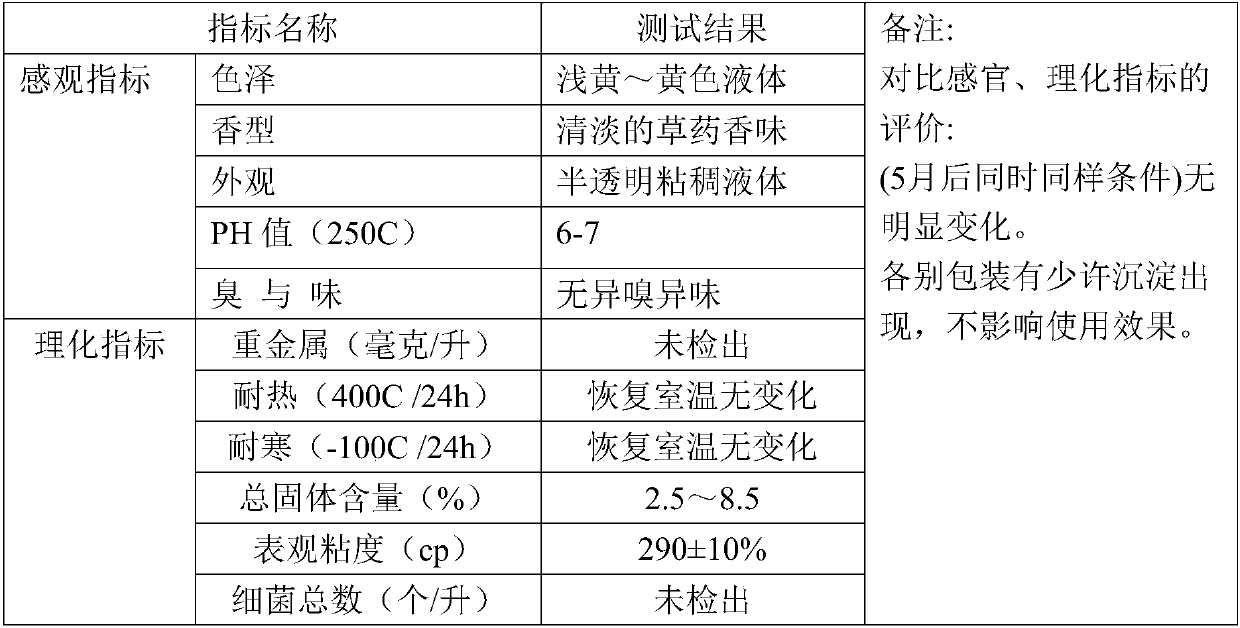

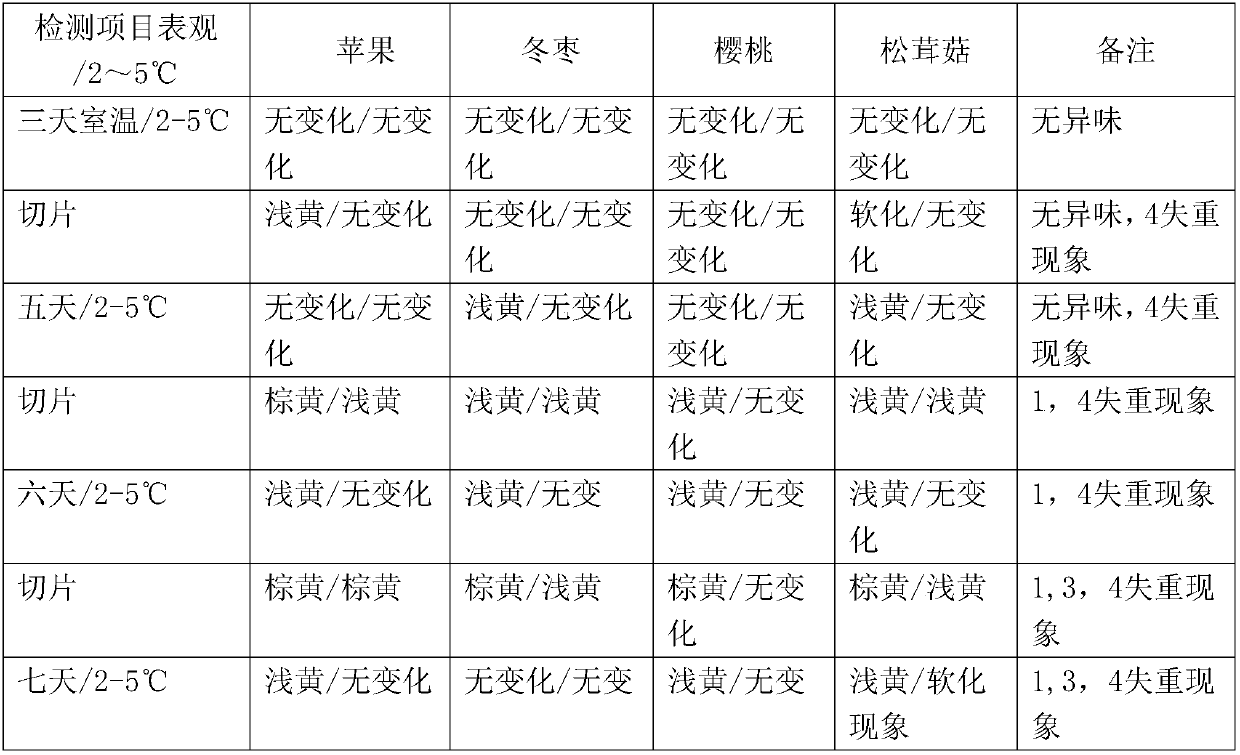

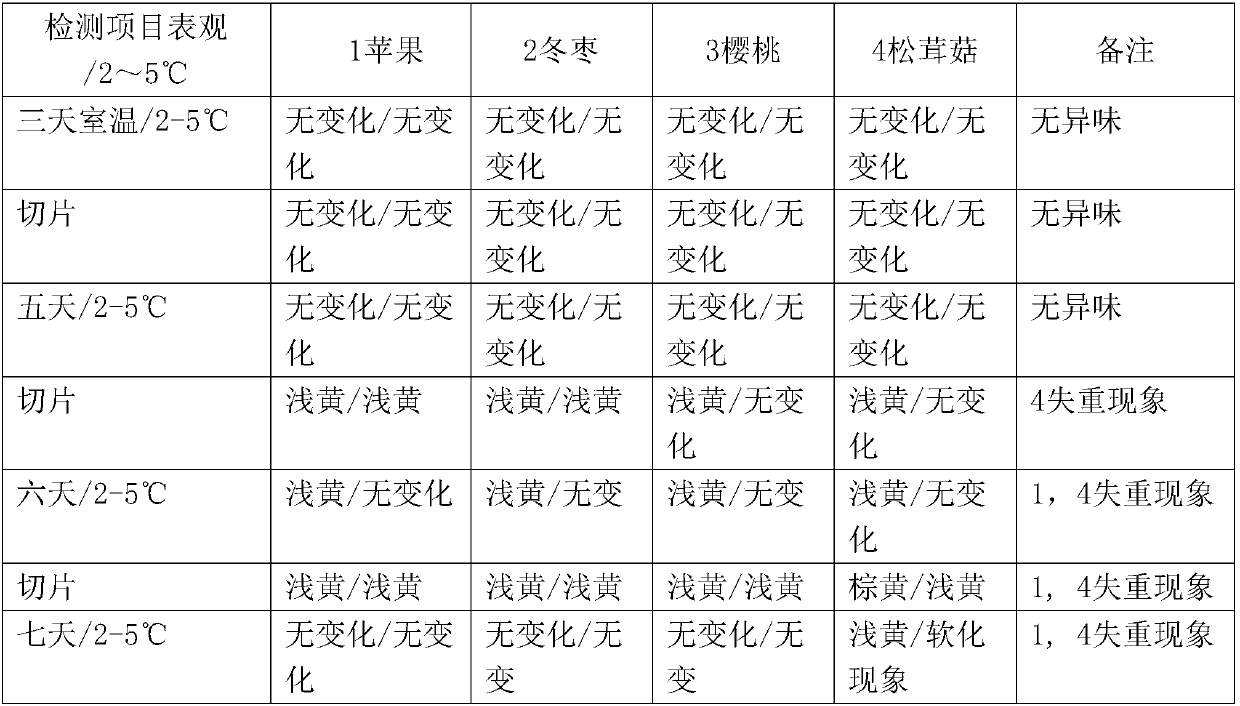

Examples

Embodiment 1

[0037] (1) Preparation of composite chitosan solution: Chitosan by mass percentage: water-soluble oligomeric chitosan: chitosan hydrochloride 10:40:50 is dissolved in 3 times the concentration of raw material quality and is 2% dilute edible Formed in aqueous acetic acid.

[0038] (2) Preparation of Chinese herbal medicine extract: obtained by heating water in the following mass percentage ratio: rosemary 1.5, wheat bran 2, grape seed 2, ginkgo fruit 1, cysteine 1, sucrose ester 1.5, ascorbic acid 0.5 , citric acid 0.5, ethylene glycol 0.05, glycerin 0.05, ultrapure water balance.

[0039] Soak rosemary, wheat bran, grape seeds, and ginkgo fruit in ultrapure water for 24 hours, then heat and reflux for 2 hours, concentrate in a vacuum until the solution density is 1.02g / cm3, and then cool down to 40°C and filter to obtain the primary plant extract; Prepare the primary plant extract with cysteine, sucrose esters, ascorbic acid, citric acid, ethylene glycol, glycerin, and ultr...

Embodiment 2

[0049] (1) Preparation of composite chitosan solution: Chitosan by mass percentage: water-soluble oligomeric chitosan: chitosan hydrochloride 20:30:50 is dissolved in 4 times the concentration of raw material quality and is 4% dilute edible Formed in aqueous acetic acid.

[0050] (2) Preparation of Chinese herbal medicine extract: obtained by heating water in the following mass percentage ratio: rosemary 5, wheat bran 4, grape seed 4, ginkgo fruit 2, cysteine 1, sucrose ester 1.5, ascorbic acid 1 , citric acid 1, ethylene glycol 1, glycerin 1, ultrapure water balance;

[0051] Soak rosemary, wheat bran, grape seeds, and ginkgo in ultrapure water for 24 hours, then heat to reflux for 2 hours, and concentrate in vacuum until the solution density is 1.02g / cm 3 , and then filtered at 40°C to obtain primary plant extracts; the primary plant extracts were prepared in proportion to cysteine, sucrose esters, ascorbic acid, citric acid, ethylene glycol, glycerin, and ultrapure water...

Embodiment 3

[0058] (1) Preparation of composite chitosan solution: Chitosan by mass percentage: water-soluble oligomeric chitosan: chitosan hydrochloride 30:30:40 is dissolved in 5 times of the concentration of raw material quality and is 6% dilute edible Formed in aqueous acetic acid.

[0059] (2) Preparation of Chinese herbal medicine extract: obtained by heating water in the following mass percentage ratio: rosemary 4, wheat bran 6, grape seed 6, ginkgo fruit 3, cysteine 1.5, sucrose ester 1.5, ascorbic acid 2 , citric acid 1.5, ethylene glycol 1.5, glycerin 1.5, ultrapure water balance;

[0060] Soak rosemary, wheat bran, grape seeds, and ginkgo in ultrapure water for 24 hours, then heat and reflux for 2 hours, and concentrate in a vacuum until the solution density is 1.03g / cm 3 , and then filtered at 40°C to obtain primary plant extracts; the primary plant extracts were prepared in proportion to cysteine, sucrose esters, ascorbic acid, citric acid, ethylene glycol, glycerin, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com