Method for reducing tar of cigarette products

A cigarette and tar technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of limited reduction of tar amount, incomplete aroma dilution, lack of satisfaction, etc., to improve chemical composition, increase potassium-chloride ratio, and improve flammability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

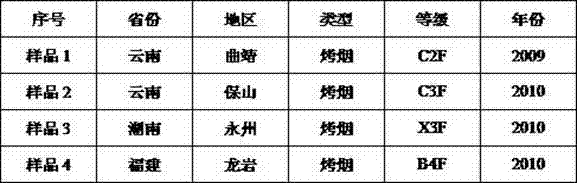

[0035] a. First slice the flue-cured tobacco flakes produced in Qujing, Yunnan (or Baoshan, Yunnan, or Longyan, Fujian, or Yongzhou, Hunan) and then perform moisture absorption and regain moisture at 65°C. 15%;

[0036] b. Loosen and rehydrate the above-mentioned sheet tobacco that has absorbed moisture and regain moisture at 57°C, so that the moisture content of the sheet tobacco after loosening and regaining moisture is 20%;

[0037] c. Blow the flue-cured tobacco leaves into atomized water at 65°C, and bake them when the moisture content of the flue-cured tobacco leaves reaches 29%.

[0038] d. When the moisture content of the above-mentioned cured tobacco leaves is 10%, blow the atomized water again at 55°C to make the moisture content of the tobacco leaves reach 20%;

[0039] E. add spices to the tobacco leaves with a moisture content of 20% in step d, shred them and regain moisture, so that the moisture content of the tobacco leaves reaches 24%;

[0040] f. Dry the abo...

Embodiment 2

[0041] Embodiment 2: the difference between this embodiment and embodiment 1 is:

[0042] a. The flue-cured tobacco sheets produced in Qujing, Yunnan (or Baoshan, Yunnan, or Longyan, Fujian, or Yongzhou, Hunan) are then subjected to moisture absorption and moisture recovery at 60°C. %;

[0043] b. Loosen and rehydrate the above-mentioned sheet tobacco that has absorbed moisture and regain moisture at 53°C, so that the moisture content of the sheet tobacco after loosening and regaining moisture is 19%;

[0044] c. Blow the flue-cured tobacco leaves into atomized water at 63°C, and bake them when the moisture content of the tobacco leaves reaches 25%.

[0045] d. When the moisture content of the above-mentioned cured tobacco leaves reaches 8%, blow in atomized water again at 53°C to make the moisture content of the tobacco leaves reach 19%;

[0046] E. adding spices to the tobacco leaves with a moisture content of 19% in step d, shredded and regaining moisture, so that the moi...

Embodiment 3

[0048] Embodiment 3: the differences between this embodiment and embodiment 1 are:

[0049] a. Slice the sliced tobacco and carry out moisture absorption and moisture recovery at 60-65°C, so that the moisture content of the tobacco sheet after moisture absorption and moisture recovery is 16%;

[0050] b. Loosen and rehydrate the above-mentioned sheet tobacco that has absorbed moisture and regain moisture at 60°C, so that the moisture content of the sheet tobacco after loosening and regaining moisture is 22%;

[0051] c. Blow the flue-cured tobacco leaves into atomized water at 68°C, and bake them when the moisture content of the tobacco leaves reaches 28%.

[0052]d. When the moisture content of the above-mentioned cured tobacco leaves reaches 10%, blow in atomized water again at 58°C to make the moisture content of the tobacco leaves reach 22%;

[0053] E. add spices to the tobacco leaves with a moisture content of 22% in step d, shred them, rehydrate, and the moisture con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com