Process for continuous preparation of caramel pigment by ammonium sulfite method

An ammonium sulfite method, caramel color technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problem that caramel color is difficult to meet high color rate and high red index, production efficiency and output at the same time. problems such as non-existence, restrictions on the use of caramel colors, etc., to achieve the effects of good product quality stability, improved production efficiency and production volume, and improved food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

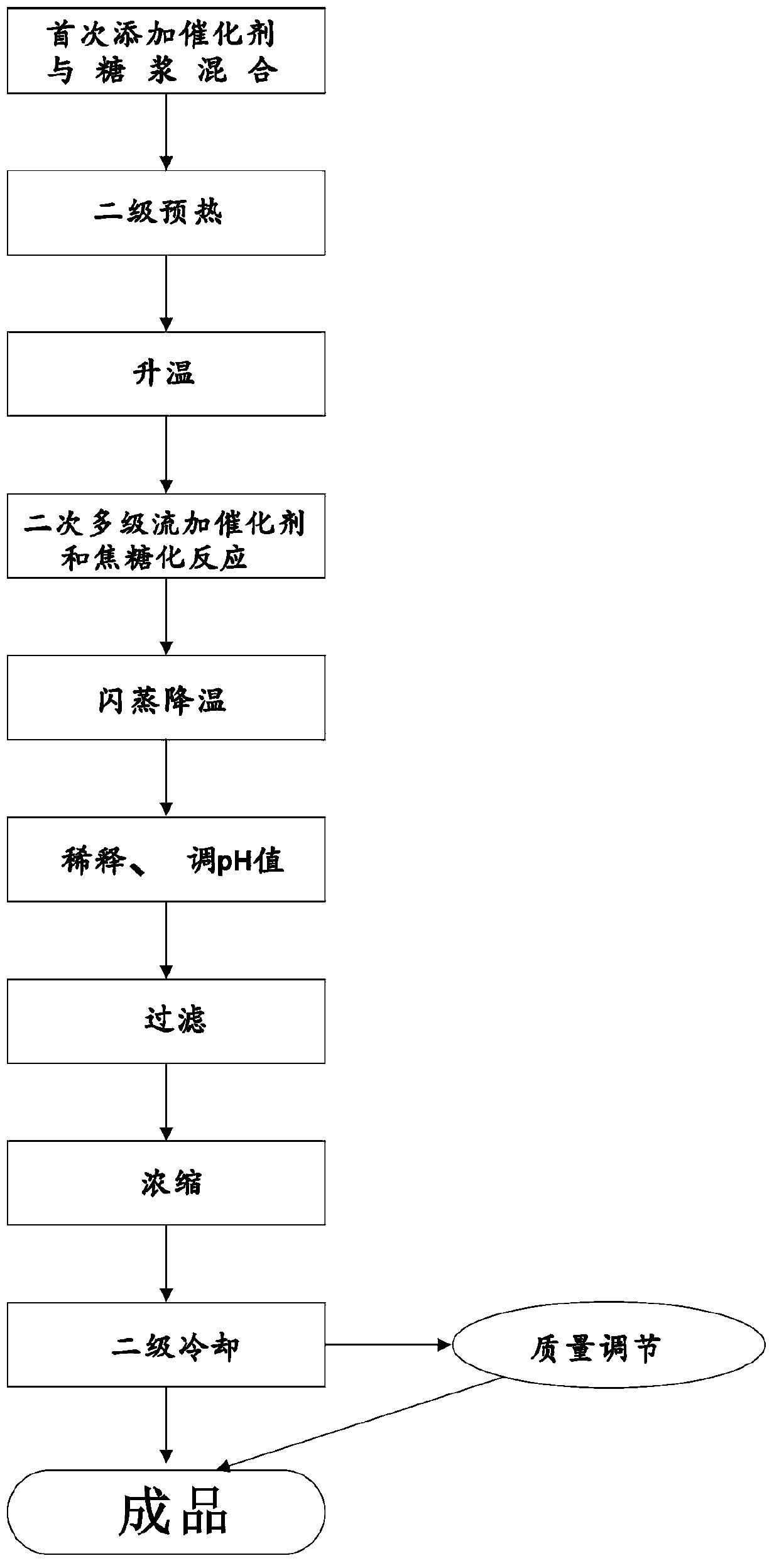

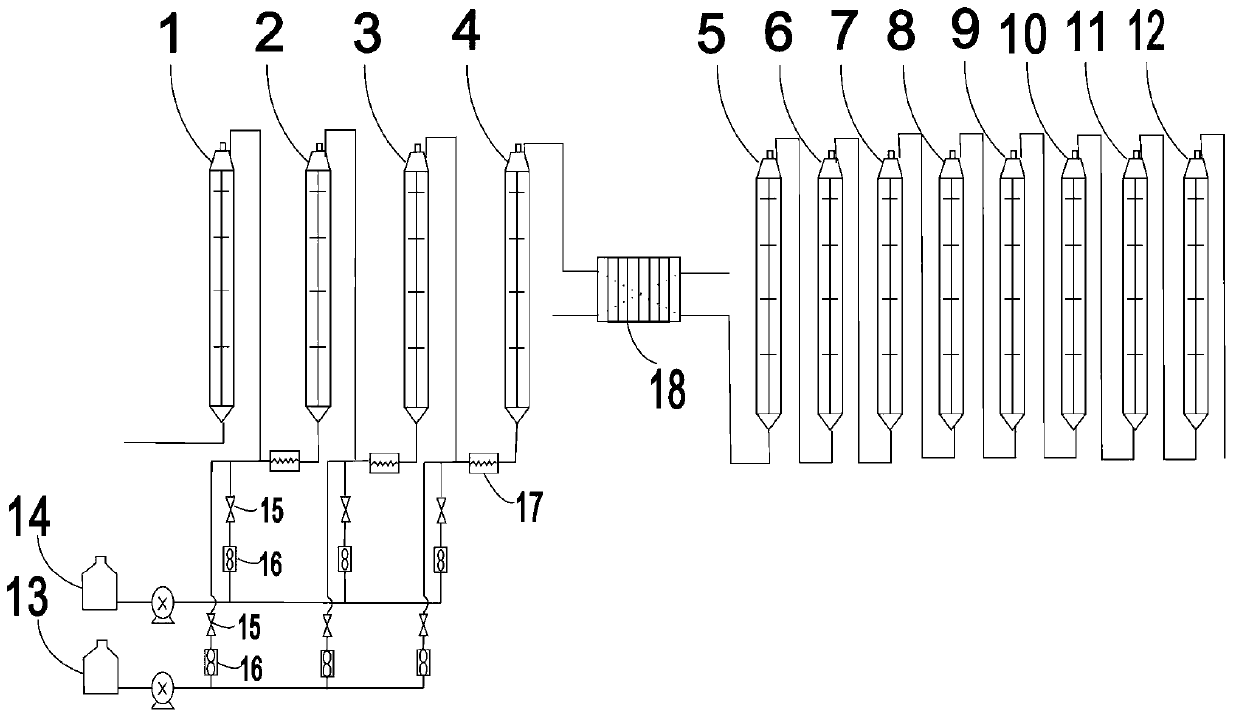

[0046] see figure 1 , a kind of ammonium sulfite method continuously prepares the technique of caramel pigment, comprises the following steps:

[0047] (1) Add catalyst and mix with syrup for the first time

[0048] A mixture of glucose syrup with 55% solid content, 1.5% (calculated as S) sodium sulfite and 2% ammonium chloride (calculated as NH4+) accounting for the solid content of the syrup is passed into the batching tank and stirred evenly.

[0049] (2) Secondary preheating

[0050] Raise the temperature of the syrup and catalyst mixture in step (1) through secondary preheating: the primary preheating is to exchange heat with the subsequent concentrated caramel pigment through the first plate heat exchanger, and raise the temperature to about 50-70°C ;Secondary preheating is heated by the secondary steam of the subsequent flash, and the temperature is raised to about 80-100°C;

[0051] (3) heating up

[0052] The syrup after the secondary preheating in step (2) is hea...

Embodiment 2

[0070] The technique for continuously preparing caramel pigment with reference to the ammonium sulfite method of embodiment 1 may further comprise the steps:

[0071] (1) Add catalyst and mix with syrup for the first time

[0072] F42 fructose syrup with a solid content of 60% and 1.0% sodium sulfite (calculated as S) and 2.0% ammonium bicarbonate (calculated as NH) in the solid content of the syrup 4+ meter) into the batching tank, and mix evenly by stirring.

[0073] (2) Secondary preheating

[0074] Raise the temperature of the syrup and catalyst mixture in step (1) through secondary preheating: the primary preheating is to exchange heat with the subsequent concentrated caramel pigment through the first plate heat exchanger, and raise the temperature to about 50-70°C ;Secondary preheating is heated by the secondary steam of the subsequent flash, and the temperature is raised to about 80-100°C;

[0075] (3) heating up

[0076] The syrup after the secondary preheating is ...

Embodiment 3

[0093] The technique for continuously preparing caramel pigment with reference to the ammonium sulfite method of embodiment 1 may further comprise the steps:

[0094] (1) Add catalyst and mix with syrup for the first time

[0095] The solid content is 46% maltose syrup and 1.5% sodium sulfite (calculated as S) and 2.5% ammonia water (calculated as NH 4+ meter) into the batching tank, and mix evenly by stirring.

[0096] (2) Secondary preheating

[0097] Raise the temperature of the syrup and catalyst mixture in step (1) through secondary preheating: the primary preheating is to exchange heat with the subsequent concentrated caramel pigment through the first plate heat exchanger, and raise the temperature to about 50-70°C ;Secondary preheating is heated by the secondary steam of the subsequent flash, and the temperature is raised to about 80-100°C;

[0098] (3) heating up

[0099] After the secondary preheating, the syrup is heated to about 140°C by mixing with steam throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color rate | aaaaa | aaaaa |

| Color rate | aaaaa | aaaaa |

| Color rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com