Yacon fruit flake and whole powder multielement joint processing production system

A technology of combined processing and production system, applied in metal processing, preservation of fruits and vegetables, peeling of vegetables or fruits, etc. Surface tension, the effect of enhancing redox ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

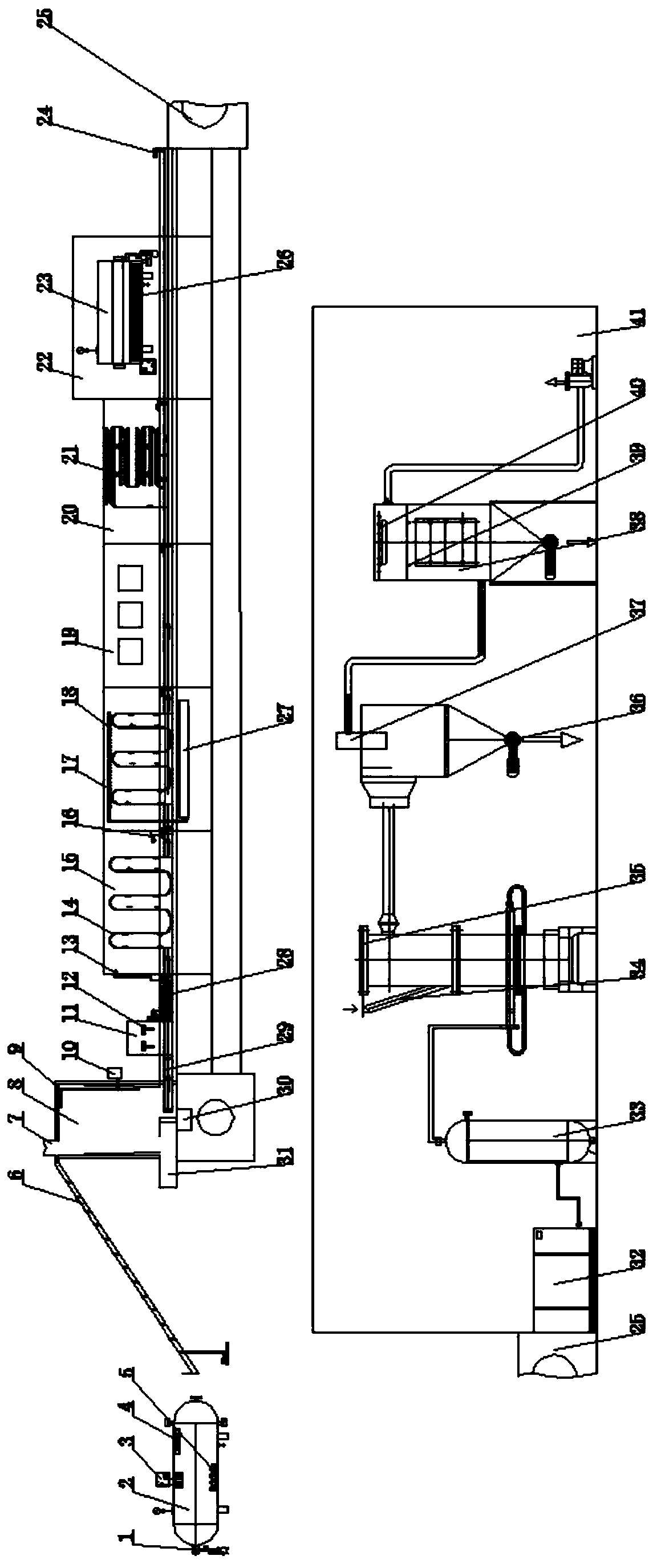

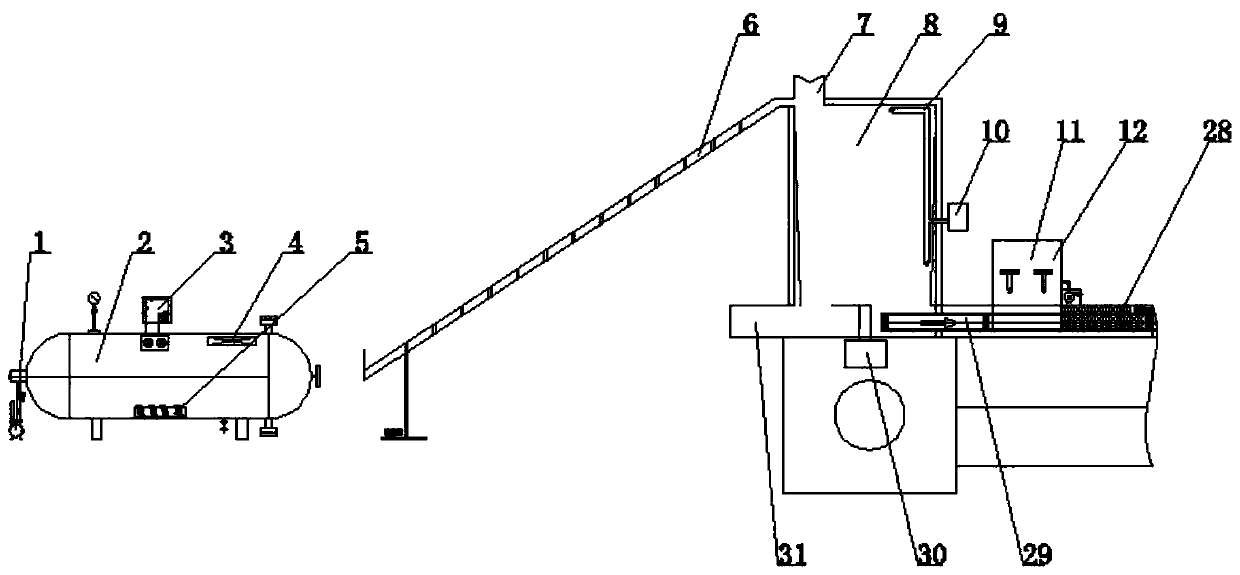

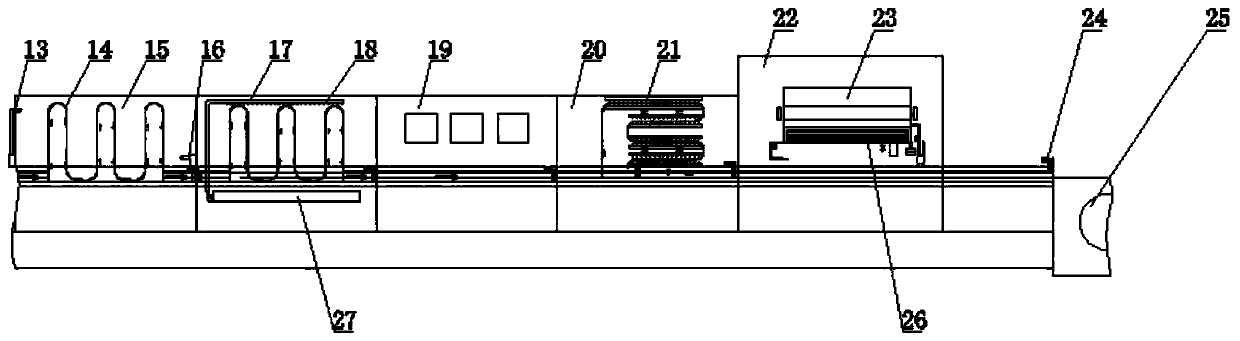

[0034] Yacon flakes and whole powder multi-component joint processing production system, the innovation of the present invention is that a pretreatment unit, a peeling and slicing unit, an anti-browning unit, an anti-caking treatment unit and a high-speed nitrogen flow are installed sequentially from the upstream to the downstream of the process Pulverizing unit 41; Described pretreatment unit comprises an airtight decompression tank 2, and this airtight decompression tank is built-in ultrasonic generating device 4 and magnetic field generating device 5; Described peeling unit comprises centrifugal peeling device and slicing device, and centrifugal Peeling and slicing devices are installed in sequence; the anti-browning unit includes an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com