Ultrasonic resistance spot welding device and method for dissimilar metal

A technology of resistance spot welding and dissimilar metals, which is applied in the direction of resistance welding equipment, metal processing equipment, welding equipment, etc., and can solve problems such as failure, phase difference ultrasonic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

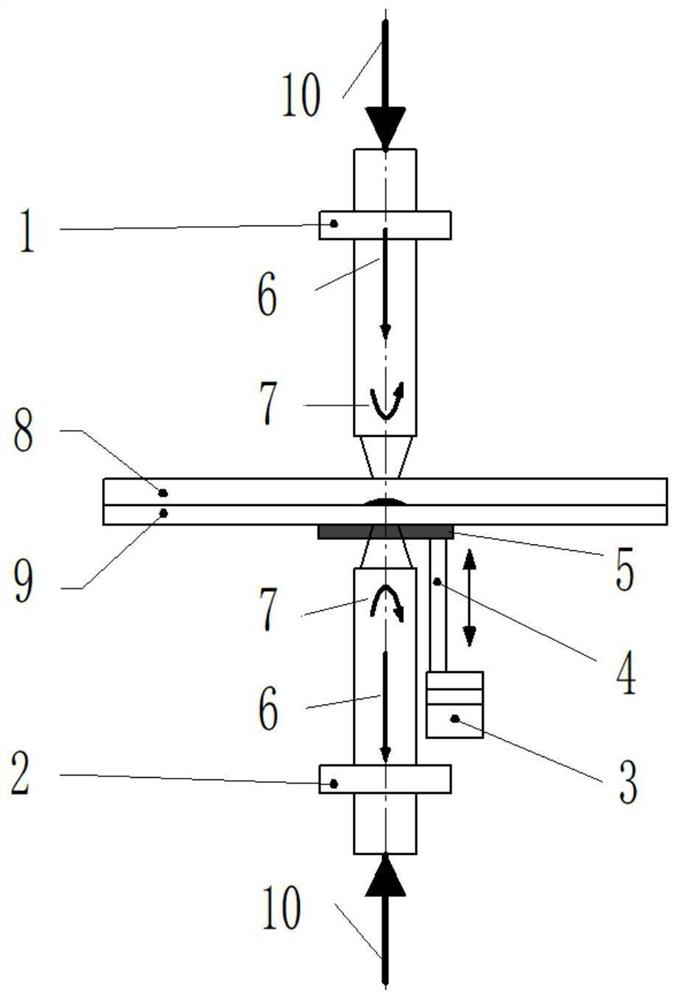

[0044] Adopt device and method of the present invention to weld 75Lx25Wx1.3Tmm3Trip780 steel and 75Lx25Wx1.6Tmm3 606l aluminum alloy workpiece, concrete operation is as follows,

[0045] The workpiece steel and the workpiece aluminum are fixed with a fixture, and the workpiece aluminum is placed above the workpiece steel. The servo control device is used to drive the first electrode and the second electrode to apply a welding force of 3200N to the workpiece to be welded. Turn on the ultrasonic generating mechanism at the same time, so that the vibrating part vibrates on the steel surface of the workpiece, the amplitude is 30 μm, and the ultrasonic frequency is 20 kHz; a welding alternating current is passed between the first electrode and the second electrode, the current amplitude is 19 kA, and the heating time is 0.3 s; in the cooling and crystallization stage, the pressure maintenance time after resistance welding is 1s, and the ultrasonic maintenance time is 0.3s.

Embodiment 2

[0047] Using the device and method of the present invention to weld 75 L x25 W x1.5 T mm 3 Trip780 steel and 75 L x25 W x2 T mm 3 606l aluminum alloy workpiece, the specific operation is as follows:

[0048] Fix the workpiece steel and workpiece aluminum with a fixture, wherein the workpiece aluminum is placed above the workpiece steel, use a servo control device to drive the first electrode and the second electrode to apply a welding force of 3400N to the workpiece to be welded, the preload time is 1s, and the welding force is 0.7s Turn on the ultrasonic generating mechanism at the same time, so that the vibrating head vibrates on the steel surface of the workpiece, the amplitude is 35 μm, and the ultrasonic frequency is 20 kHz; the welding AC current is passed between the first electrode and the second electrode, the current amplitude is 22 kA, and the heating time is 0.4 s; in the cooling and crystallization stage, the pressure maintenance time after resistance weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com