A method for extracting chlorogenic acid from fresh leaves of Eucommia ulmoides by utilizing biotechnology

A technology of eucommia chlorogenic acid and fresh leaves of eucommia ulmoides, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid esters, etc., can solve the problems of low honeysuckle resources and high cost of chlorogenic acid, etc. Achieve the effects of improving structural strength and service life, shortening extraction time, and increasing extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) select 20kg Eucommia ulmoides fresh leaf that plucks in May-August and beat through beater;

[0034] (2) After adding 80kg of pure water at 40°C and pH 6, use 20kHz frequency ultrasonic wave to assist extraction for 30min, and filter to obtain the crude extract of eucommia chlorogenic acid;

[0035] (3) Add 20 g of a stabilizer to the crude extract of Eucommia chlorogenic acid, and stir at 30° C. for 10 min;

[0036] (4) The crude extract of eucommia chlorogenic acid in step 3 was mixed with 5.5m 3 / h flow rate, flow through the purified resin, and then rinse the resin with absolute ethanol 0.5 times the volume of the purified resin bed, leaching out a small amount of chlorogenic acid remaining in the resin, and collecting the filtrate after the resin flows out;

[0037] (5) Concentrate the filtrate in step 4 under reduced pressure at -0.05-0.09MPa and 40°C until the solvent is completely recovered, then vacuum-dry at -0.05-0.09MPa and 60°C to obtain the finished c...

Embodiment 2

[0045] (1) select 20kg Eucommia ulmoides fresh leaf that plucks in May-August and beat through beater;

[0046] (2) After adding 80kg of pure water at 40°C and pH 6, use 20kHz frequency ultrasonic wave to assist extraction for 30min, and filter to obtain the crude extract of eucommia chlorogenic acid;

[0047] (3) Add 20 g of a stabilizer to the crude extract of Eucommia chlorogenic acid, and stir at 30° C. for 10 min;

[0048] (4) The crude extract of eucommia chlorogenic acid in step 3 was mixed with 5.5m 3 flow rate per hour, flow through the purified resin, and then rinse the resin with absolute ethanol 0.5 times the volume of the purified resin bed, leaching out a small amount of chlorogenic acid remaining in the resin, and collecting the filtrate after the resin flows out;

[0049] (5) Concentrate the filtrate in step 4 under reduced pressure at -0.05-0.09MPa and 40°C until the solvent is completely recovered, then vacuum-dry at -0.05-0.09MPa and 60°C to obtain the fini...

Embodiment 3

[0098] Based on Example 1, set the comparative example 1 that does not add chitosan acetic acid solution, the comparative example 2 that does not add modifier, the comparative example 3 that removes impurities by HPD826 resin, do not add epoxy soybean oil and hydrogenated castor The comparative example 4 of sesame oil.

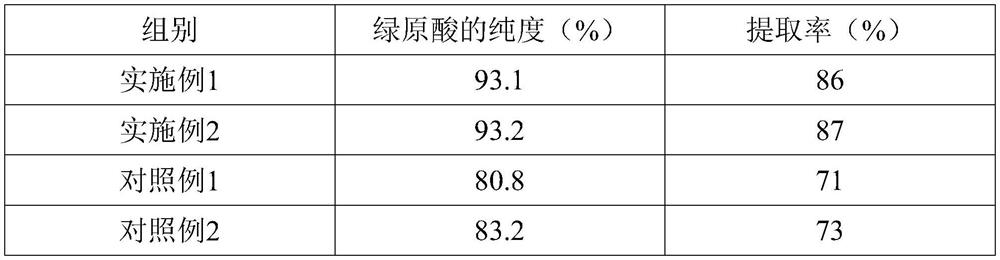

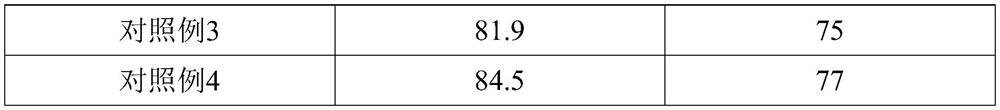

[0099] Using Examples 1-2 and Comparative Examples 1-4 to extract chlorogenic acid in the fresh leaves of Eucommia ulmoides, the purity and extraction rate of chlorogenic acid are shown in Table 1.

[0100] The purity and extraction efficiency of table 1 chlorogenic acid

[0101]

[0102]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com