Method for producing packing paper board by explosion pulp of oil palm fruit shell

A technology of oil palm fruit and packaging cardboard, which is applied in the field of pulp and paper making, and achieves the effects of high yield, high ring compressive strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

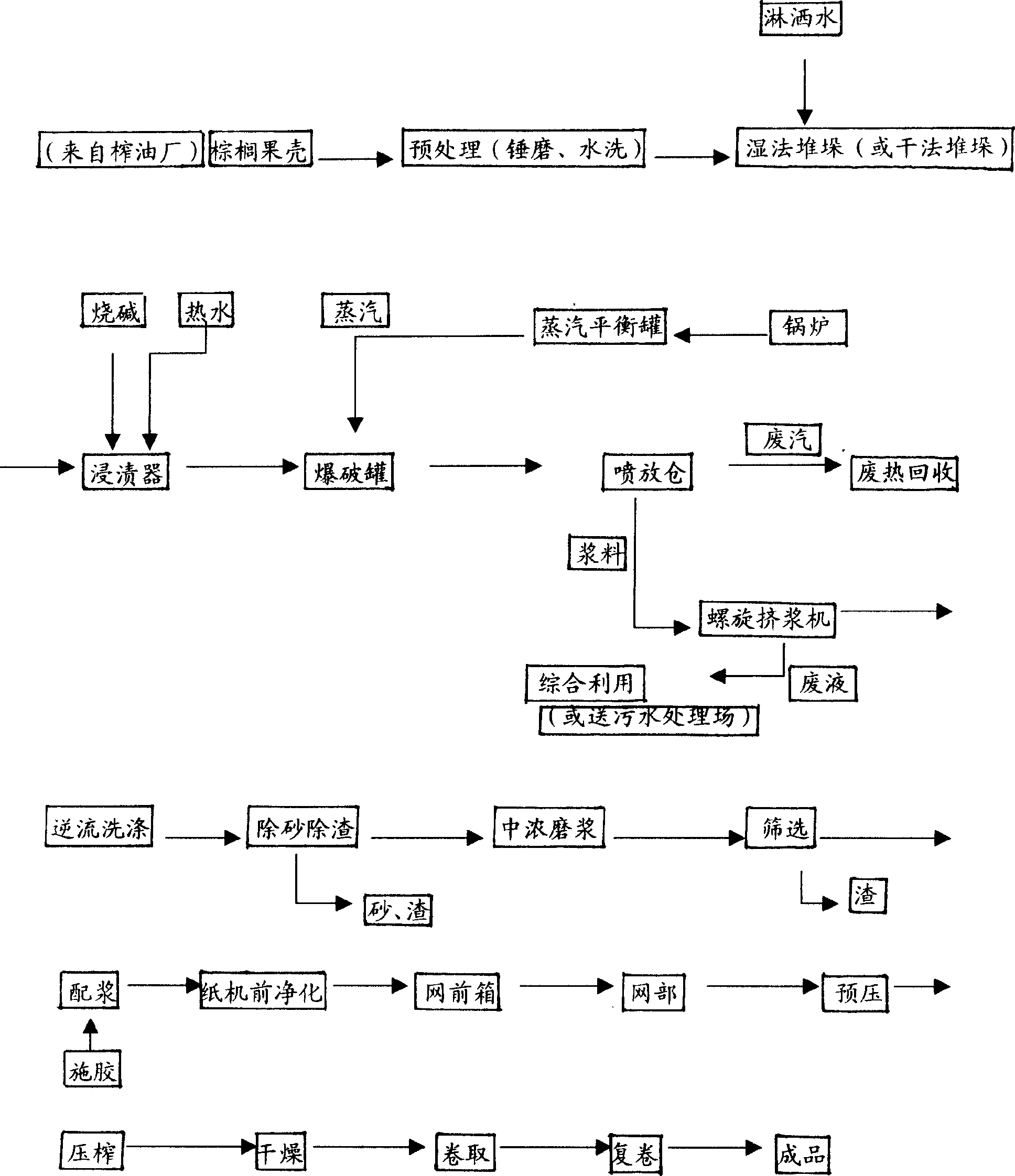

Method used

Image

Examples

example 2

[0032] Example 2. Blending of oil palm husk blasting pulp and waste paper pulp to produce A-grade corrugated base paper

[0033] The oil palm husk explosion pulp was prepared according to the production flow and process conditions of Example 1.

[0034] Waste paper pulp is made from old corrugated boxes and waste cement bags that are crushed by a high-concentration hydraulic pulper, and then passed through a heat dispersion system, sand removal, slag removal, washing, refining, and purification. The beating degree of waste paper pulp is 26-28°SR.

[0035] Ratio of pulp: 70% of oil palm shell blasting pulp, 30% of waste paper pulp. Pulp sizing: sizing the mixed pulp in the pulp mixing tank, the amount of rosin glue is 2% of dry fiber, and the amount of aluminum sulfate is 3%.

[0036] Finished product quality: Quantitative 116g / m 2 , tightness 0.55g / cm 3 , the transverse ring pressure index is 7.8Nm / g, and the longitudinal fracture length is 4450m. The quality of the finis...

example 3

[0037] Example 3: Combining oil palm husk blasting pulp with waste paper pulp and kraft wood pulp for kraft vermicelli boxboard

[0038] The preparation of oil palm husk blasting pulp is carried out according to the production process and process conditions of Example 1, and the preparation of waste paper pulp is carried out according to the production process and process conditions of Example 2. Kraft wood pulp is wood pulp made by crushing with a high-consistency hydraulic pulper, then through medium-consistency refining, screening and purification, dyeing and sizing.

[0039]Kraft wood pulp beating degree is 34-36°SR

[0040] Kraft wood pulp flavoring; dyeing and sizing in the pulp chest of the wood pulp production process. The dosage of basic orange is 0.04% of the dry fiber, and the dosage of basic bright yellow is 0.02% of the dry fiber. The amount of rosin glue is 2% of the dry fiber amount, and the amount of aluminum sulfate is 3%.

[0041] Ratio of pulp: kraft wood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

| Longitudinal fracture length | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com