Preparation method of tobacco-sourced basic cigarette-smell raw material

A technology for tobacco and raw materials, applied in the field of tobacco, can solve the problems of insufficient aroma richness, insufficient harmony of aroma, lack of aroma and the like, and achieve the effects of good aroma quality, few harmful components and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

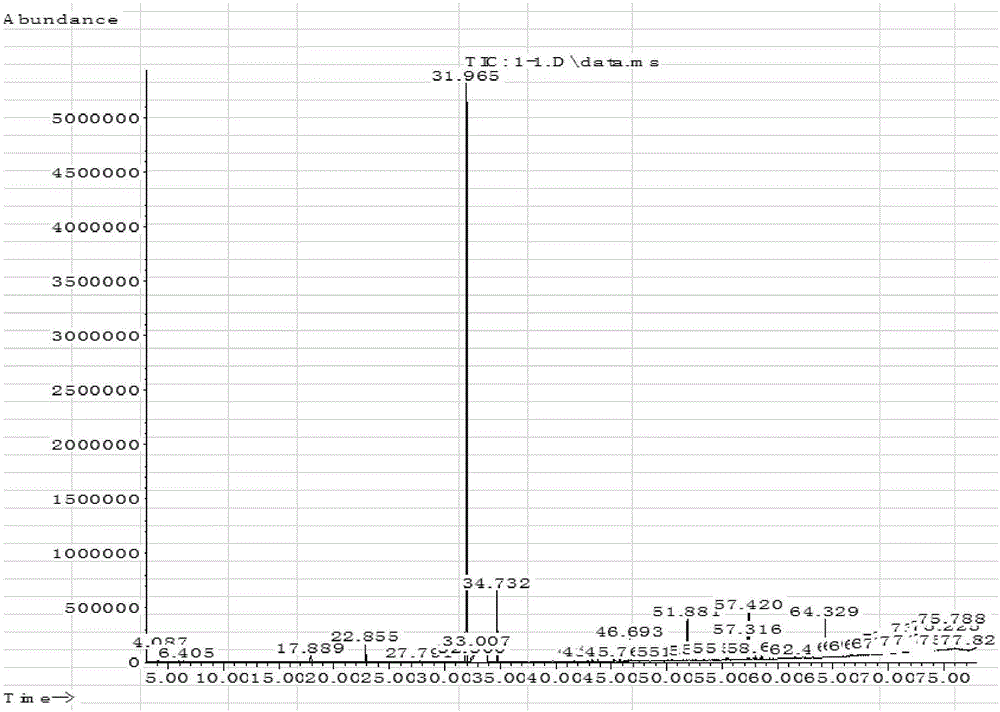

Image

Examples

Embodiment 1

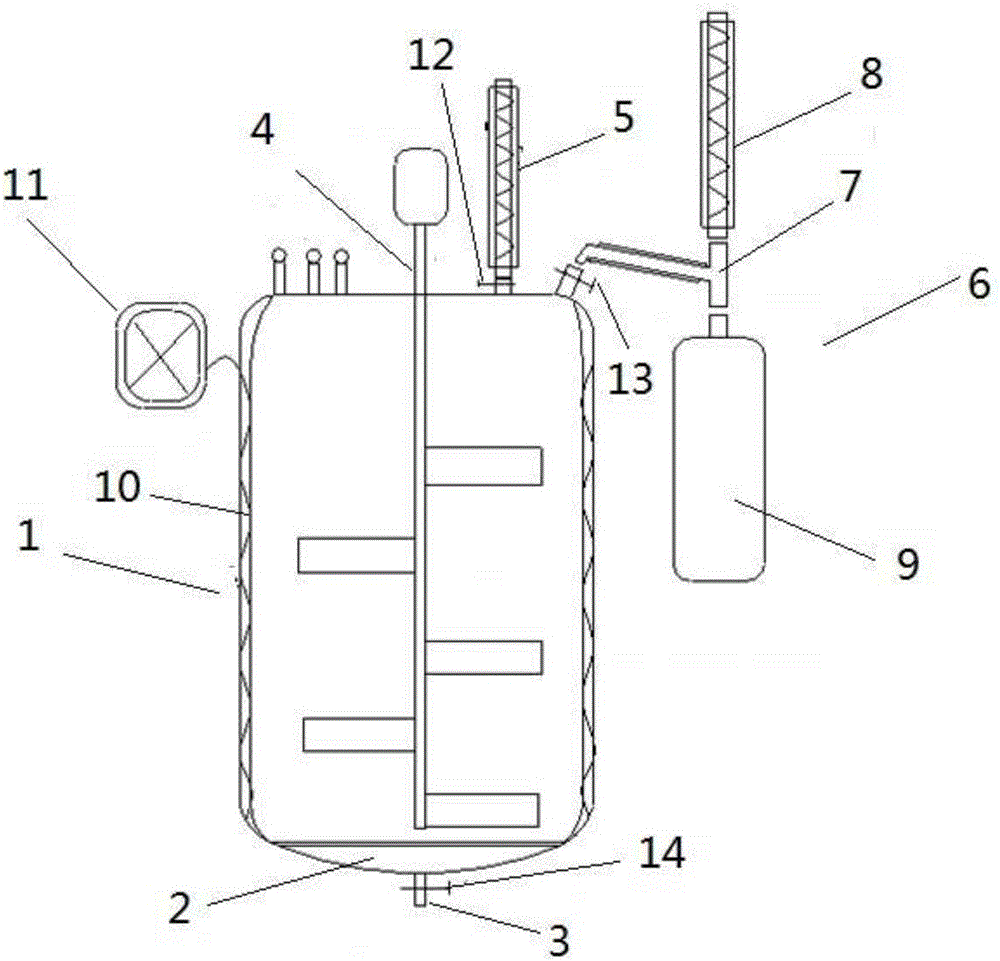

[0035] Close the valve B of the special retort pyrolysis cooling device in advance (the condensation collection device is not used in this embodiment), open the valve A, keep the cooling temperature (water used as coolant) at a constant temperature of 4°C, and keep the heating temperature at a constant temperature of 230°C. System tightness. Weigh 50g of 60-mesh Hunan Jiangyong 2014 flue-cured tobacco C3F powder and quickly put it into a special retort pyrolysis cooling device, immediately seal the system, and at the same time turn on the stirring motor and adjust the speed to 250 rpm to stir the tobacco raw materials. After heating for 25 minutes, Remove the heat source, after the dry distillation pyrolysis bottle is naturally cooled, add 6 times the weight of 95% ethanol aqueous solution at 60°C, stir and reflux for extraction for 2.5 hours, after releasing the extract, add 5 times the weight of 95% ethanol aqueous solution at 60°C Stir and reflux for extraction for 1.5h, re...

Embodiment 2

[0060] Close in advance the valve B of the special retort pyrolysis cooling device (same as embodiment 1) capable of bearing pressure (the present embodiment does not use the condensation collection device), open the valve A, and keep the cooling temperature (using ethylene glycol aqueous solution as coolant) constant temperature to -5°C, the heating temperature is constant to 260°C, and the airtightness of the system is checked. Weigh 50g of 20-mesh Zimbabwe 2014 L1O grade flue-cured tobacco powder and quickly put it into a special retort pyrolysis device, immediately close the system, and at the same time turn on the stirring motor and adjust the speed to 300 rpm to stir the tobacco raw materials. After heating for 20 minutes, put Remove the heat source, and after the dry distillation pyrolysis bottle is naturally cooled, add 6 times the weight of 60% ethanol-40% ethyl acetate solution, stir and reflux at 60°C for 3 hours, and after releasing the extract, add 5 times the weig...

Embodiment 3

[0063] Cut the self-made flue-cured tobacco leaf group with a shredder twice, and sieve about 1mm 2 Left and right size smoke slices. Close the valve B of the special retort pyrolysis cooling device (same as embodiment 1) in advance (the condensation collection device is not used in this embodiment), open the valve A, and keep the cooling temperature (using ethylene glycol aqueous solution as the coolant) at a constant temperature of -10°C , The heating temperature is constant to 330°C, and the airtightness of the system is checked. Put the above 1mm 2 After quickly adding 60g of left and right large and small tobacco pieces into the special dry distillation pyrolysis direct cooling device, immediately close the system, and at the same time turn on the stirring motor and adjust the speed to 600 rpm to stir the tobacco raw materials. After heating for 15 minutes, remove the heat source. After the dry distillation pyrolysis bottle is naturally cooled, add 5 times the weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com