Method for extracting basic smoke smell raw material of tobacco source for electronic cigarettes

An extraction method and technology of e-cigarette liquid, which is applied in the field of tobacco, can solve the problems of lack of extract aroma, ineffective extraction, and low extraction yield, so as to achieve rich tobacco aroma, good consistency, and solve burnt smell Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The essence of this example is to compare the difference in the crude extraction solvent system between the scheme described in the present invention and the scheme described in the reference document (CN104585859A), resulting in differences in the obtained products. The specific operation is as follows:

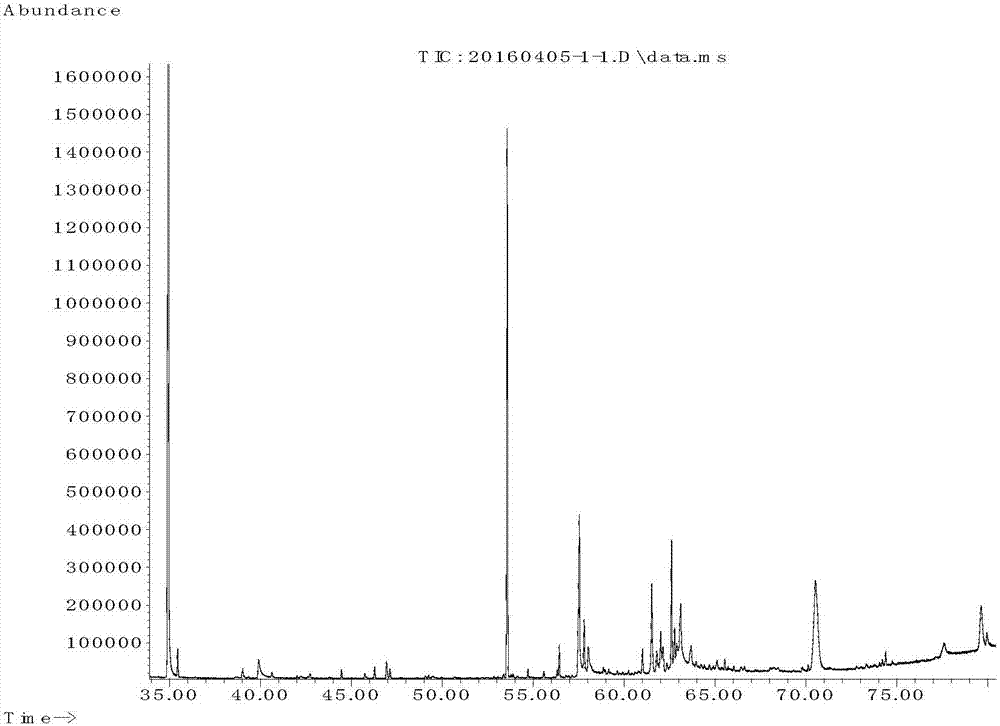

[0051] Each weighs 40g of the same middle tobacco leaf group 20 mesh powder 40g in two 500mL round bottom flasks, and adds 200g of absolute ethanol to the sample numbered 20160405-1 (this is the scheme of the reference (CN104585859A)), and the number is A composite solvent composed of 200 g of absolute ethanol, chloroform, and petroleum ether (ratio 65:20:15, m / m) was added to the sample of 20160405-2 (ie, the scheme described in the present invention). Put the two sample vials into a magnetic stirring water bath at the same time, reflux and stir at 50°C for 3h, release the extraction solvent, concentrate to dryness under reduced pressure on a rotary evaporator at 55°...

Embodiment 2

[0058] Take by weighing the upper part tobacco leaf group 40 order powder 50g that mixes in 500mL round bottom flask, add the composite solvent that 300g dehydrated alcohol, ethyl acetate, chloroform, No. 6 solvent oils form (ratio is 55:20:15: 10, m / m), put it in a magnetic stirring water bath at 52°C for reflux and stir for 2.5h, filter out the extraction solvent, and concentrate under reduced pressure on a rotary evaporator at 60°C with the strongest negative pressure of -0.092Mpa. Dry. The recovered solvent was added back to the round-bottomed flask filled with tobacco raw materials, refluxed and stirred at 55°C for 2 hours, then filtered out the extraction solvent, and reduced to -0.095Mp on a rotary evaporator at 45°C and the strongest negative pressure was -0.095Mp. Concentrate to dryness under pressure. Combine the dry matter after twice concentration, add 80 g of organic solvent system A (ethyl acetate:dichloromethane=2:8, m / m) and stir as hard as possible to obtain ...

Embodiment 3

[0061] Weigh 100g of 20 mesh powder of flue-cured tobacco C2F sheet tobacco produced in Yuxi, Yunnan Province in 2013 and put it in a 1000mL round bottom flask, add 500g of absolute ethanol, dichloromethane, 30-60°C boiling range petroleum ether to form a composite solvent (the ratio is 60:25 :15, m / m), after soaking for 30min, airtight decompression (-0.03MPa) maintained for 30min, then placed in a magnetic stirring water bath at 38°C for reflux and stirring for extraction for 2h, filtered out the extraction solvent, and placed on a rotary evaporator for 37 °C and the strongest negative pressure is -0.092Mpa and concentrated to dryness under reduced pressure. The recovered solvent was added back to the round-bottomed flask filled with tobacco raw materials, refluxed and stirred at 38°C for 1.5 hours, then filtered out the extraction solvent, and placed on a rotary evaporator at 37°C with the strongest negative pressure of -0.09Mp Concentrate to dryness under reduced pressure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com