Method for cultivating halophilic microorganisms to produce ectoine and hydroxy ectoine

A technology for hydroxytetrahydropyrimidine and halophilic microorganisms is applied in the field of culturing halophilic microorganisms to produce tetrahydropyrimidine and hydroxytetrahydropyrimidine, and can solve the problems of inhibiting growth, decreasing the synthesis amount of tetrahydropyrimidine, affecting the yield of hydroxytetrahydropyrimidine, etc. , to achieve the effect of improving the synthesis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

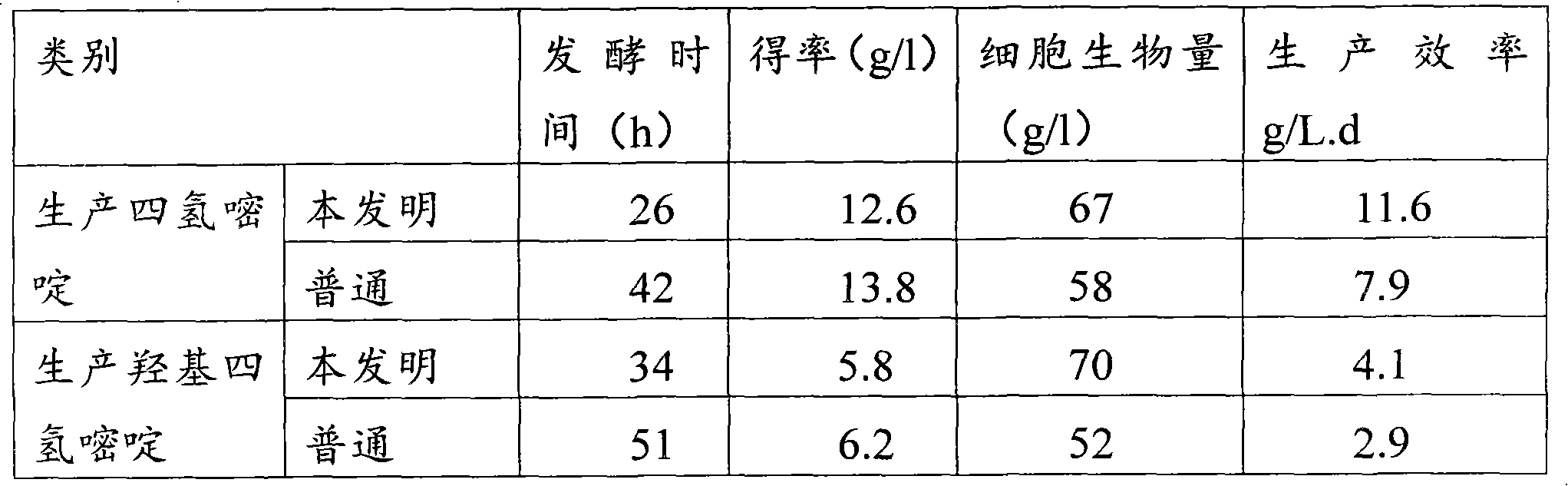

Embodiment 1

[0029] 1. Take an inoculation loop and connect the Halomonas ventosae DL7 strain to a test tube containing 6ml of liquid nutrient medium on a clean bench, and culture it in a shaker at 240rpm at 30°C for 20h for activation.

[0030] 2. Into a 500ml Erlenmeyer flask containing 50ml of seed culture medium, insert 2.5ml of the above-mentioned activated bacterial solution, culture on a shaker at 240rpm at 30°C for 24h, and culture 3 flasks in parallel. Seed medium (1L): glucose 10g, sodium chloride 58.4g, ammonium chloride 2g, magnesium sulfate 2g, dipotassium hydrogen phosphate 0.6g, yeast extract 1g, peptone 1g.

[0031] 3. Insert 150ml of seed bacterial liquid in a 5L fermenter with 3L fermentation medium, 800 rpm, pH control at 7.0-7.2, and ventilation at 0.2-0.4v / v.min (per minute per volume of culture Based on the volume ratio of sterile air), start to feed after 10 hours of fermentation, keep the glucose concentration at about 20g / l, cultivate at 30°C for 18 hours, add NaCl...

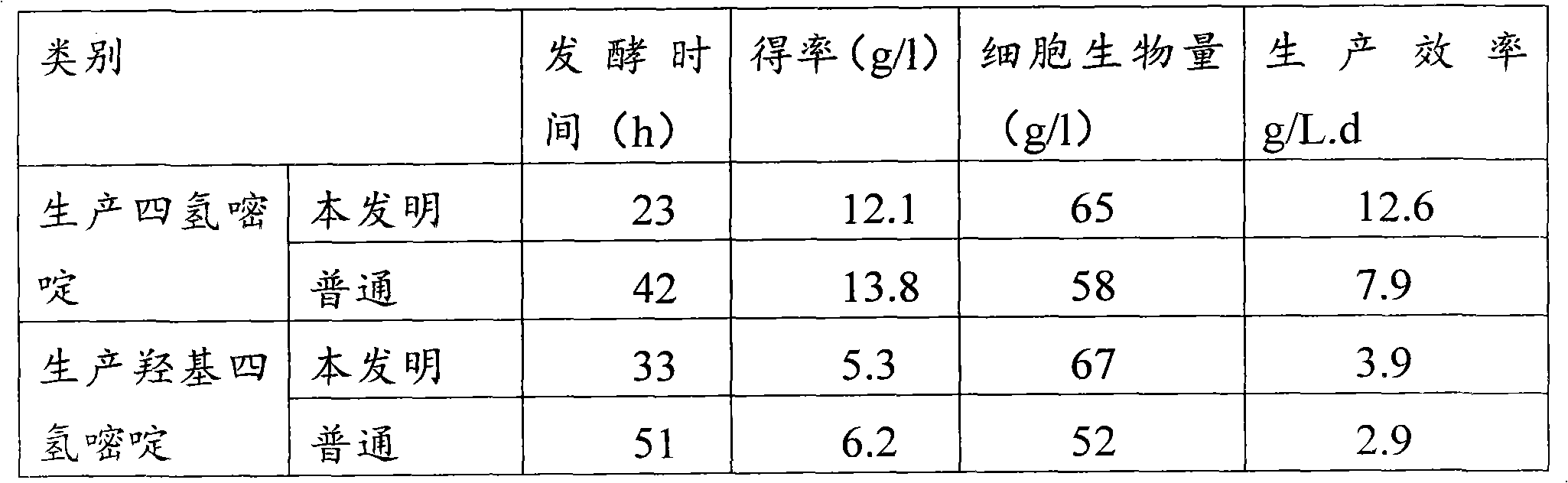

Embodiment 2

[0036] 1. Take an inoculation loop and connect the Halomonas ventosae DL7 strain to a test tube containing 6ml of liquid nutrient medium on a clean bench, culture it in a shaker at 240rpm at 30°C for 18h for activation.

[0037] 2. Into a 500ml Erlenmeyer flask containing 50ml of seed culture medium, insert 2.5ml of the above-mentioned activated bacterial solution, and culture on a shaker at 240rpm at 30°C for 18h, and culture 3 flasks in parallel. Seed medium (1L): glucose 10g, sodium chloride 58.4g, ammonium chloride 2g, magnesium sulfate 2g, dipotassium hydrogen phosphate 0.6g, yeast extract 1g, peptone 1g.

[0038] 3. Insert 150ml of seed bacterial liquid in a 5L fermenter with 3L fermentation medium, 800 rpm, pH control at 7.0-7.2, and ventilation at 0.2-0.4v / v.min (per minute per volume of culture Based on the volume ratio of sterile air), start to feed after 10 hours of fermentation, keep the glucose concentration at about 20g / l, cultivate at 30°C for 20 hours, add NaCl...

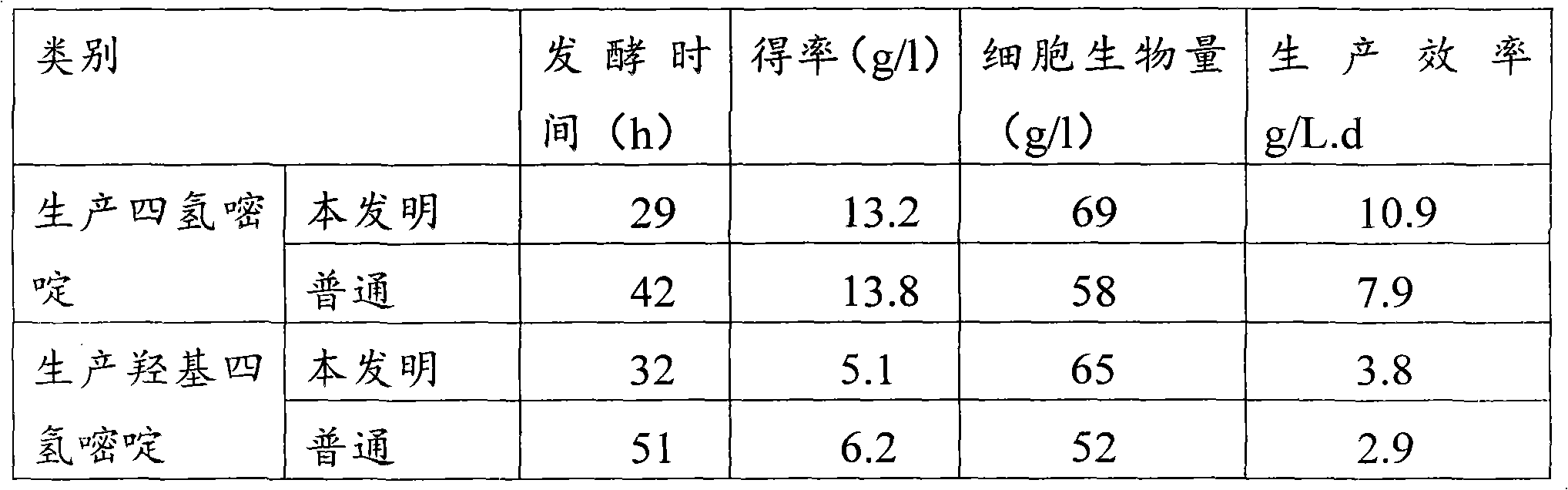

Embodiment 3

[0043] 1. Take an inoculation loop and connect the Halomonas ventosae DL7 strain to a test tube containing 6ml of liquid nutrient medium on a clean bench, and culture it in a shaker at 240rpm at 30°C for 24h for activation.

[0044] 2. Into a 500ml Erlenmeyer flask containing 50ml of seed medium, insert 2.5ml of the above-mentioned activated bacterial solution, and culture on a shaker at 240rpm at 30°C for 20h, and culture 3 flasks in parallel. Seed medium (1L): glucose 10g, sodium chloride 58.4g, ammonium chloride 2g, magnesium sulfate 2g, dipotassium hydrogen phosphate 0.6g, yeast extract 1g, peptone 1g.

[0045] 3. Insert 150ml of seed bacterial liquid in a 5L fermenter with 3L fermentation medium, 800 rpm, pH control at 7.0-7.2, and ventilation at 0.2-0.4v / v.min (per minute per volume of culture Based on the volume ratio of sterile air), start to feed after 10 hours of fermentation, keep the glucose concentration at about 20g / l, cultivate at 30°C for 24 hours, add NaCl to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com