A kind of high temperature resistant modified epoxy resin adhesive and preparation method thereof

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, adhesive, carboxyl rubber adhesive, etc. It can solve the problems of unsatisfactory high-temperature bonding performance, unsatisfactory thermal oxidation stability, and unsuitability for large-area bonding. , to achieve high practical value, moderate viscosity and low brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

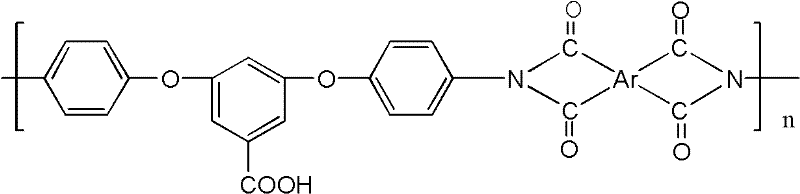

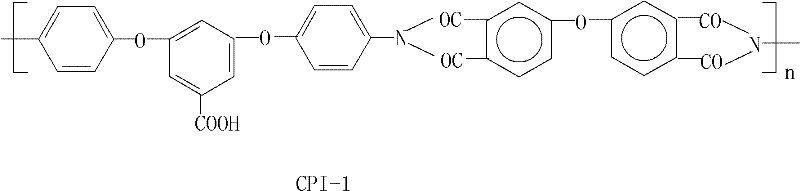

[0029] Add 0.1 mole (33.6 grams) of 3,5-bis(4-aminophenoxy)benzoic acid and 300 milliliters of N,N-dimethylacetamide as a highly polar aprotic organic solvent into the polymerization bottle, stir Dissolve, add 0.1 mole (31.0 g) of 3,3',4,4'-tetracarboxylic diphenyl ether dianhydride powder, and react at 0°C-10°C for 5-10 hours to obtain a transparent PAA solution, add 300 ml of toluene azeotropic dehydration agent, then heat azeotropic dehydration until the azeotropic dehydration is complete, about 6 hours, then heat the reaction system to distill and concentrate to about 1 / 3, stir and precipitate in acetone at a high speed to prepare The obtained carboxyl group-containing polyimide CPI-1 powder has an intrinsic viscosity of 0.62 dL / g (25°C, concentrated sulfuric acid).

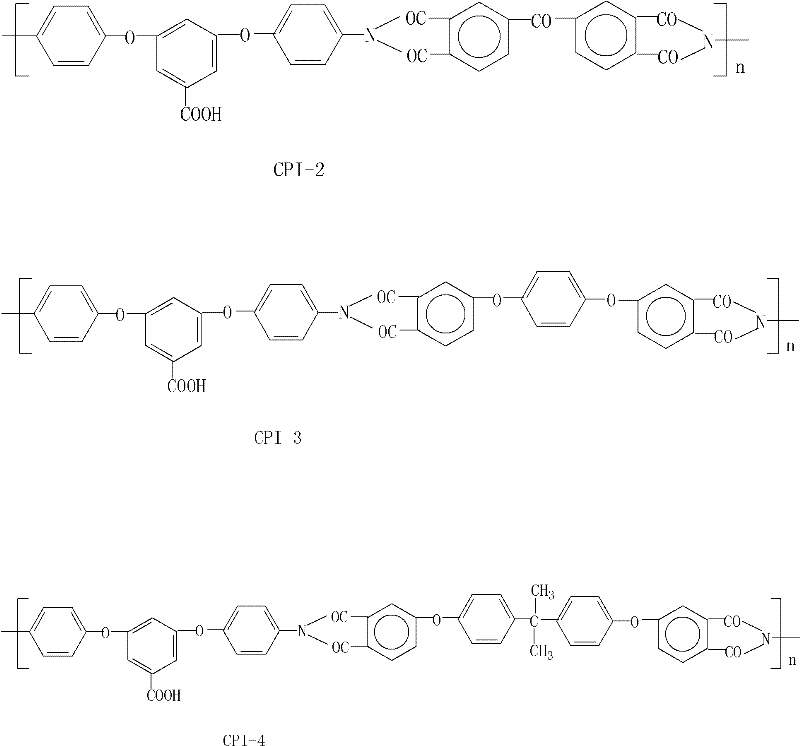

[0030] Using 3,3',4,4'-tetracarboxylic benzophenone dianhydride, 1,4-bis(3,4-dicarboxyphenoxy)phthalic anhydride, 2,2-bis[4-(3 , the aromatic dianhydride of 4-dicarboxyphenoxy) phenyl] propane dianhydride re...

Embodiment 2

[0035] TGDDM epoxy resin: 58.0 grams

[0036] CTBN carboxy-terminated nitrile rubber: 6.75 grams

[0037] CPI-4 powder: 1.0 g

[0038] Dicyandiamide curing agent: 4.0 grams

[0039] 1,3-Diglycidyloxybenzene diluent: 30.25 grams

[0040] Stir the above ingredients evenly at room temperature to obtain the carboxyl-containing polyimide modified epoxy adhesive. Its use effect can reach the purpose of the invention.

Embodiment 3

[0042] ES216 epoxy resin: 56.8 grams

[0043] CTBN carboxy-terminated nitrile rubber: 6.6 grams

[0044] CPI-3 powder: 3.0 grams

[0045] 2-ethyl-4-methylimidazole curing agent: 1.8 grams

[0046] Dicyandiamide curing agent: 2.15 grams

[0047] 2,2-bis(4-glycidyloxycyclohexyl)propane diluent: 15.2 grams

[0048]Vinyl cyclohexene dioxide thinner: 14.46 grams

[0049] Stir the above ingredients evenly at room temperature to obtain the carboxyl-containing polyimide modified epoxy adhesive. Its use effect can reach the purpose of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com