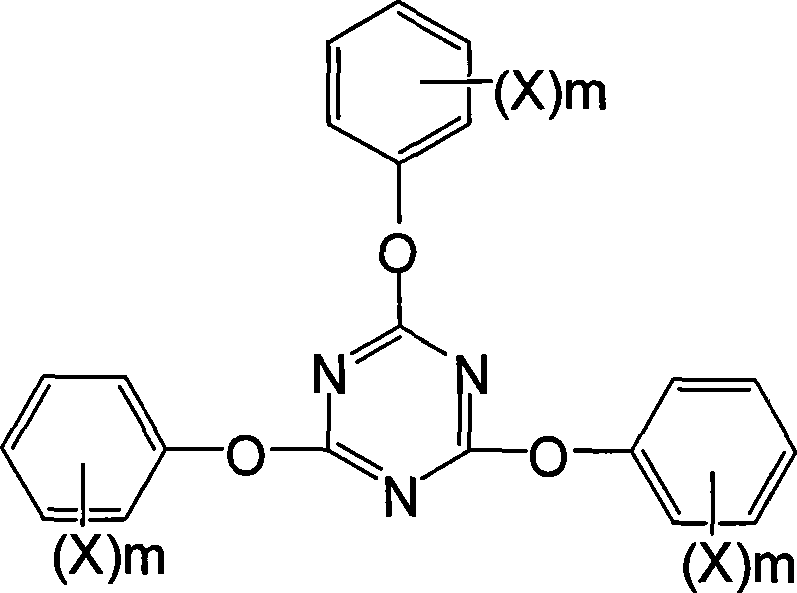

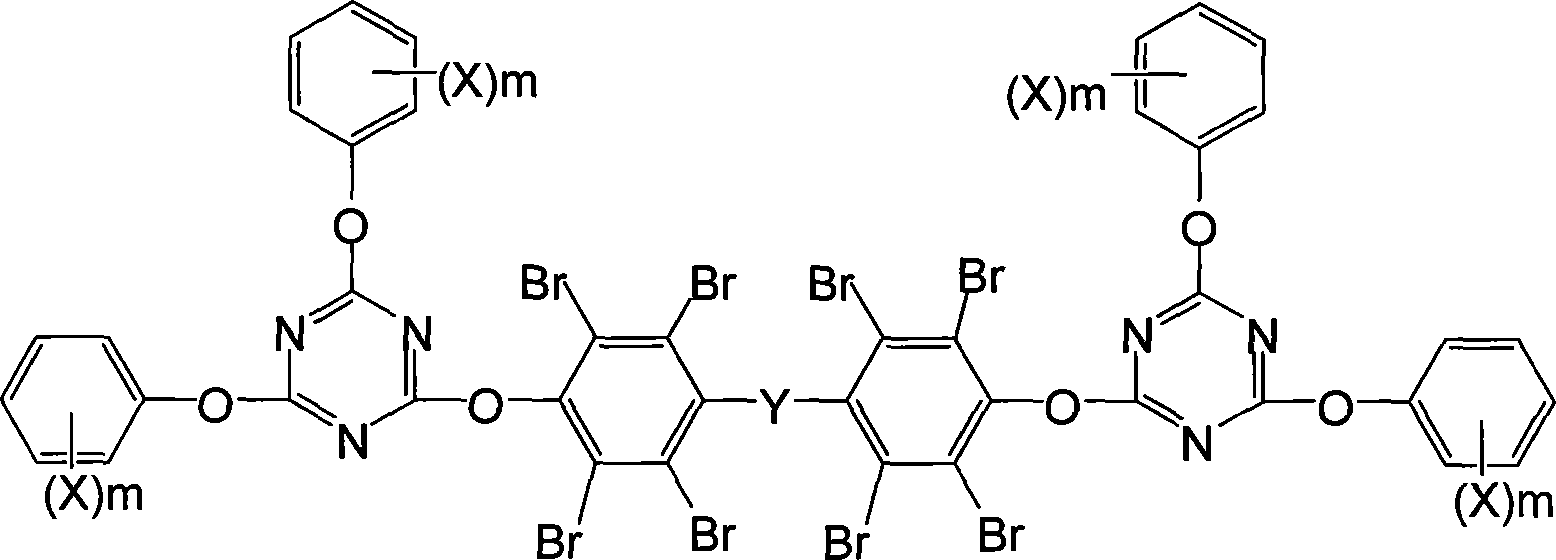

Method for preparing polybromophenoxy-substituted striazine fire-retardant compound

A technology of polybromophenoxy and bromophenoxy, which is applied in the field of preparation of flame retardant compounds, can solve the problems of unavoidable cyanuric chloride feeding pollution, troublesome separation operation process, insufficient homogeneous method, etc., and achieves a good Market application prospects, avoiding high reaction temperature, and avoiding the effect of high product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 500mL four-neck flask equipped with a stirrer, thermometer, reflux condenser, and dropping funnel, add 25g (0.136mol) cyanuric chloride, 135g (0.408mol) 2,4,6-tribromophenol, 0.44g (0.00136mol) tetrabutylammonium bromide, 100ml solvent 1, 2-dichloroethane began to stir and cooled, when the temperature was cooled below 10°C, add dropwise from 16.3g (0.408mol) hydroxide in advance through the dropping funnel 5% alkaline aqueous solution prepared with sodium, control the addition rate, keep the system temperature not exceeding 10°C, after about 0.5h after the dropwise addition, raise the temperature to 30°C-60°C and continue the reaction for 2h, then distill and recover the solvent, and then cool down the system to room temperature, filter and add an appropriate amount of water to wash the filter cake until the filtrate becomes clear, collect the filter cake, and dry to obtain 143.3 g of white crystalline powder, with a yield of 98.7%, a melting point of 227°C-229°C, a...

Embodiment 2

[0030] 2,4,6-tribromophenol addition is increased to 140g (0.422mol), and sodium hydroxide is increased to 16.9g (0.422mol), and other is with embodiment 1, slightly, obtains product 142.3g, and yield is 98.5%.

Embodiment 3

[0032] Catalyst tetrabutylammonium bromide is increased to 4.4g (0.0136mol), and other is with embodiment 1, example 2, omission, and product yield reaches 97.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com