Preparation method of linear water-based polyurethane thickener containing hydrophobic side bases

A technology for water-based polyurethane and thickener, applied in the field of polyurethane, can solve the problems of complicated synthesis steps of hydrophobic diol chain extender, and achieve the effect of obvious thickening effect, increasing viscosity and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

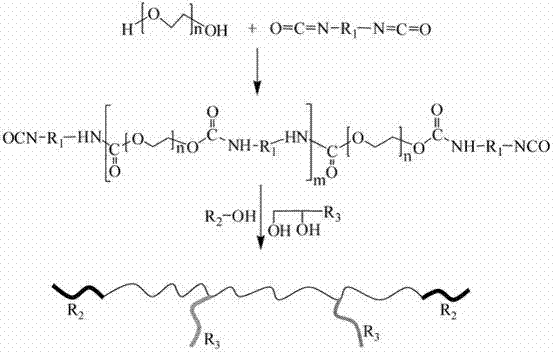

[0022] A preparation method of a linear water-based polyurethane thickener containing hydrophobic side groups, the preparation steps are:

[0023] Mix 40wt% ~ 50wt% polymer diol and 22wt% ~ 30wt% diisocyanate, in N 2 Stir for 1h to 3h at 50°C to 70°C in air, then add 10wt% to 18wt% end-capping agent, stir at 50°C to 70°C for 1h to 3h to obtain a polyurethane prepolymer, and then add it to the prepared Add 12wt%-20wt% chain extender to the obtained polyurethane prepolymer, and stir at 50°C-70°C for 1h-3h to prepare a linear water-based polyurethane thickener containing hydrophobic side groups.

[0024] In this embodiment: the molecular weight of polyethylene glycol is 1000-4000, the diisocyanate is isophorone diisocyanate, the blocking agent is n-octanol, and the chain extender is 1,2-decanediol.

Embodiment 2

[0026] A preparation method of a linear water-based polyurethane thickener containing hydrophobic side groups, the preparation steps are:

[0027] Mix 48wt%~55wt% of polymer diol, 15wt%~25wt% of diisocyanate and 0.5wt%~2wt% of catalyst, in N 2 Stir at 70-90°C for 2.5h-4.5h, then add 15wt%-25wt% end-capping agent, and stir at 70-90°C for 2.5h-4.5h to obtain a polyurethane prepolymer, then Add 8wt%-16wt% chain extender to the prepared polyurethane prepolymer, and stir at 70-90°C for 2.5-4.5h to prepare a linear water-based polyurethane thickener containing hydrophobic side groups.

[0028] In this embodiment: the molecular weight of polyethylene glycol is 4000-6000, the diisocyanate is toluene diisocyanate, the catalyst is triethylenediamine, the end-capping agent is dodecyl alcohol, and the chain extender is 1,2-dodecane diisocyanate alcohol.

Embodiment 3

[0030] A preparation method of a linear water-based polyurethane thickener containing hydrophobic side groups, the preparation steps are:

[0031] Mix 52wt% ~ 60wt% polymer diol, 10wt% ~ 18wt% diisocyanate and 2wt% ~ 4wt% catalyst, in N 2 Stir for 4h-6h at 80°C-100°C in air, then add 22wt%-30wt% end-capping agent, stir for 4h-6h at 80°C-100°C to prepare polyurethane prepolymer, and then add to the prepared Add 5wt%-10wt% chain extender to the obtained polyurethane prepolymer, and stir at 80°C-100°C for 4h-6h to prepare a linear water-based polyurethane thickener containing hydrophobic side groups.

[0032] In this embodiment: the molecular weight of polyethylene glycol is 6000-8000, the diisocyanate is diphenylmethane diisocyanate, the catalyst is dibutyltin dilaurate, the end-capping agent is myristyl alcohol, and the chain extender is 1,2- Tetradecanediol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com