Boron carbide silicon carbide composite ceramic and preparation method thereof

A technology of boron carbide silicon carbide and composite ceramics, which is applied in the field of ceramic materials, can solve the problems of reducing the hardness of products and its high-temperature mechanical properties, difficult to use precision structural engineering, and poor high-temperature mechanical properties, etc., and meets the requirements of fine grain and particle size Good effect of low and high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

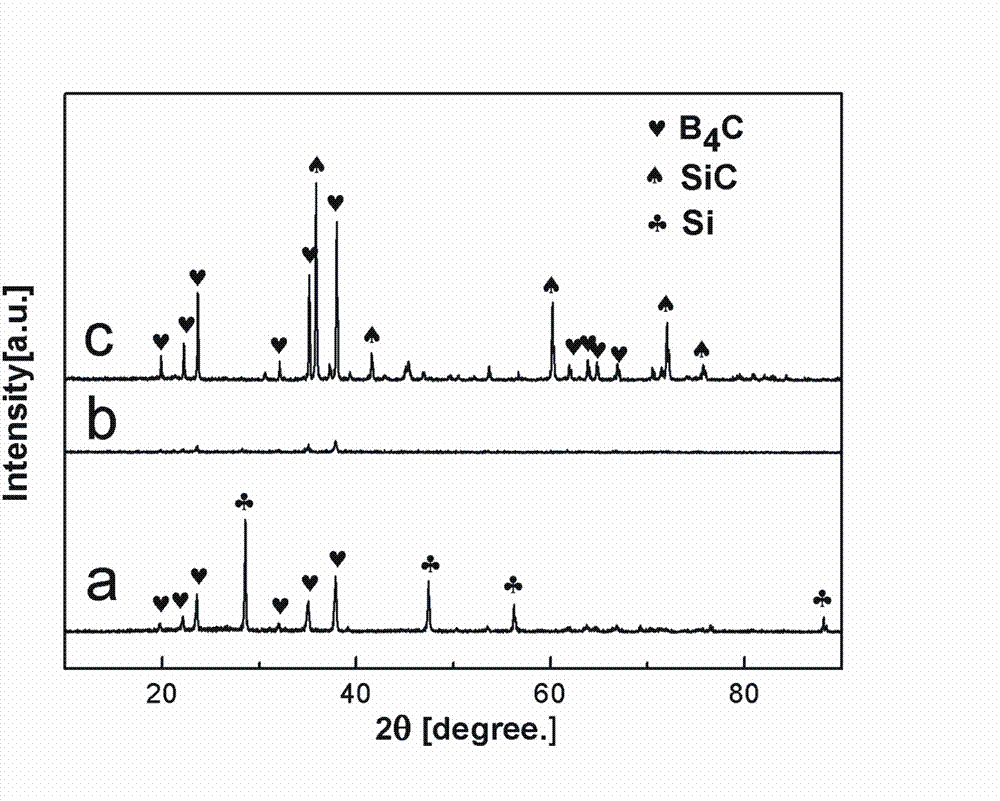

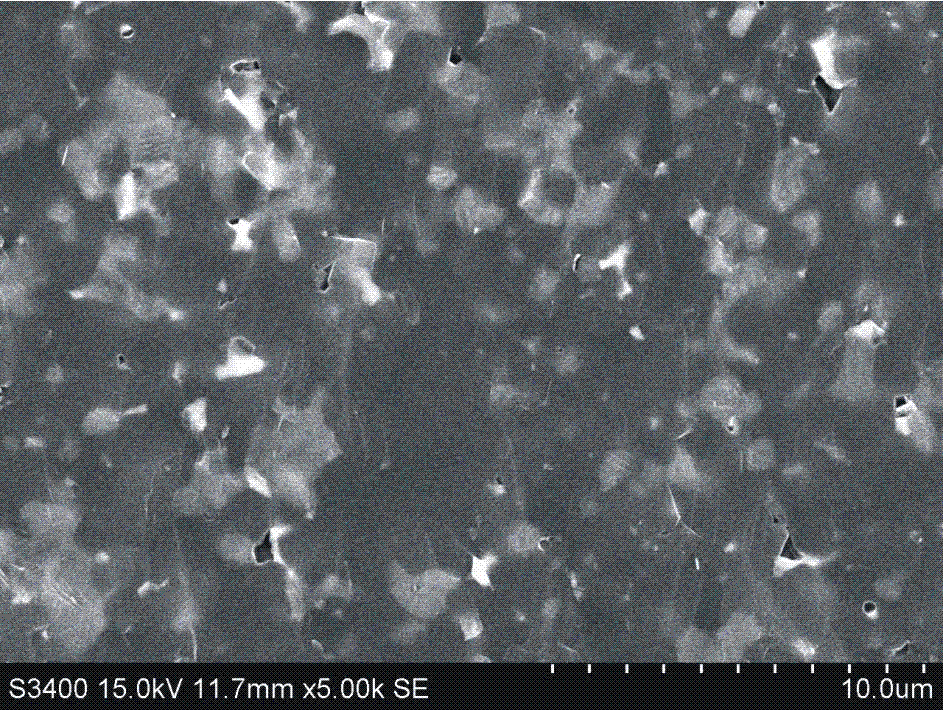

Embodiment 1

[0037] A boron carbide silicon carbide composite ceramic, the mass ratio of boron carbide to silicon carbide in the boron carbide silicon carbide composite ceramic is 4:1, which is made of boron carbide, amorphous carbon powder and silicon powder ternary mixed powder through mechanical After alloying, it is sintered by reactive hot pressing technology. The ternary mixed powder includes 80% boron carbide powder (purity is 97%, particle size is 75um) and amorphous carbon powder 6 % (98% purity, 1um particle size), 14% silicon powder (99% purity, 75um particle size).

[0038] The preparation method of boron carbide silicon carbide composite ceramics described in this embodiment, the specific steps include:

[0039] 1) Preparation of amorphous highly active boron carbide, carbon and silicon composite powder

[0040] 1. By weight percentage, taking by weighing purity is 97%, and particle diameter is the boron carbide powder of 75um; Purity is 98%, and particle diameter is the amor...

Embodiment 2

[0049] A boron carbide silicon carbide composite ceramic, the mass ratio of boron carbide to silicon carbide in the boron carbide silicon carbide composite ceramic is 4:1, which is mechanically alloyed by a ternary mixed powder of boron carbide, carbon black and silicon powder Finally, it is sintered by reaction hot pressing technology. The ternary mixed powder in terms of weight percentage includes 80% boron carbide powder (purity is 97%, particle size is 75um), carbon black 6% (purity is 98%, particle size 1um), silicon powder 14% (purity 99%, particle size 75um).

[0050] The preparation method of boron carbide silicon carbide composite ceramics described in this embodiment, the specific steps include:

[0051] 1) Preparation of amorphous highly active boron carbide, carbon and silicon composite powder

[0052] ①By weight percentage, take by weighing the boron carbide powder with a purity of 97% and a particle size of 75um; a carbon black with a purity of 98% and a particl...

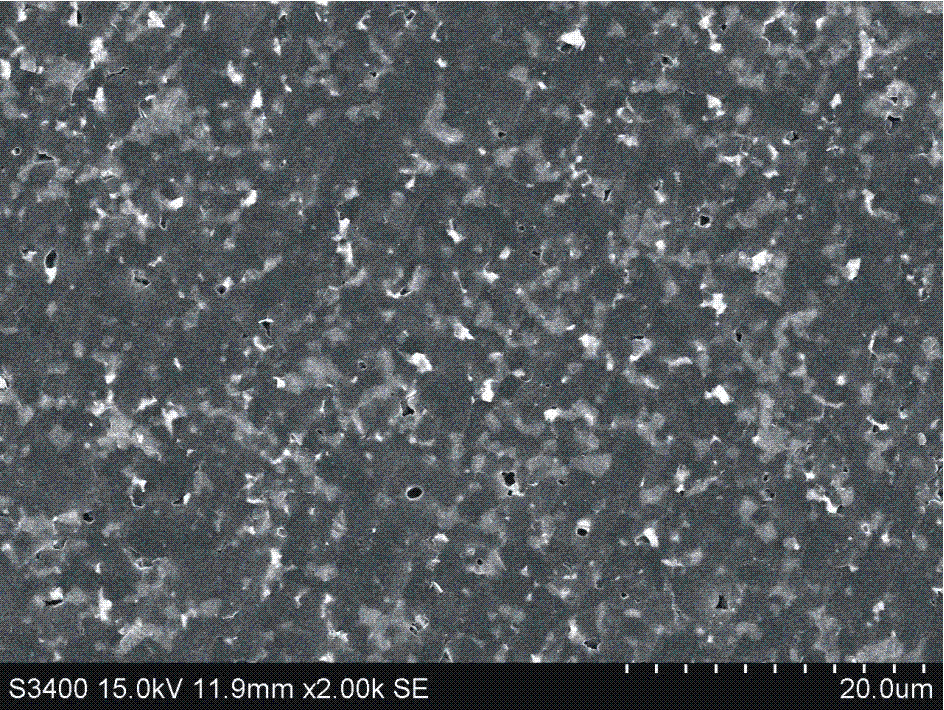

Embodiment 3

[0059] The difference between this embodiment and embodiment 2 is that the weight percentages of boron carbide powder, carbon black and silicon powder are 90%, 3% and 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com