Hetero atom-doped three dimensional porous carbon material, preparation method and application thereof

A three-dimensional porous and heteroatom technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of immature production technology of three-dimensional porous carbon materials, and achieve a simple and rapid preparation method, controllable conditions, and increased contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

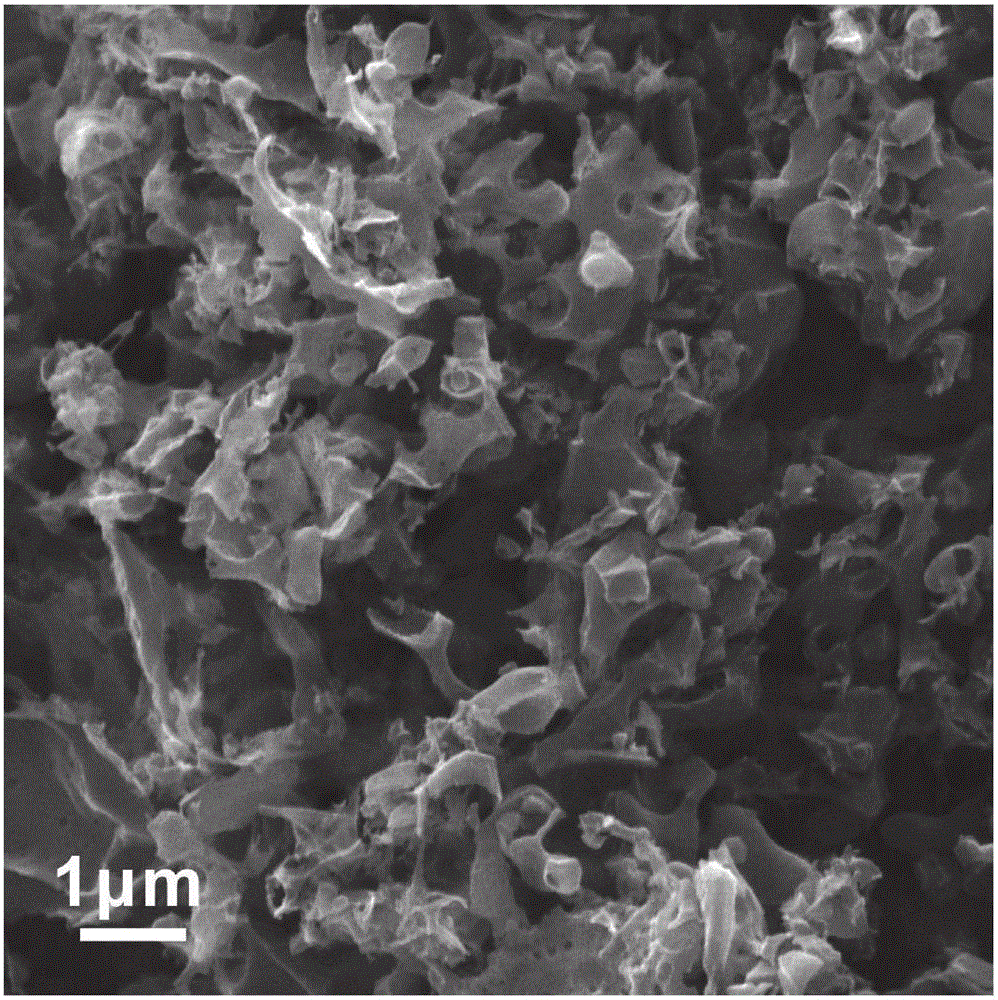

[0037] Mix 0.2g of carbon quantum dots with 1.0g of sodium hydroxide and 0.8g of sodium phosphate evenly, and then calcinate them at 900°C for 2h under the protection of an inert gas, with a heating rate of 10°C / min, and cool down naturally. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, separate it by vacuum filtration, wash it with deionized water for 5 times, and dry it in vacuum at 100°C for 12 hours. The black powder obtained is phosphorus Doped three-dimensional porous carbon materials. figure 1 In the scanning electron micrograph of the phosphorus-doped three-dimensional porous carbon material, a porous three-dimensional structure can be observed. figure 2 Optical photograph of the prepared phosphorus-doped three-dimensional porous carbon material powder, which appears as a fluffy black powder.

[0038] Mix the obtained carbon material, sodium carboxymethyl cellulose, and conductive carbon...

Embodiment 2

[0040] 0.2g of carbon quantum dots and 3.0g of sodium hydroxide and 1.6g of B 2 o 3 Mix evenly, and then calcinate at 1000°C for 2h under the protection of inert gas, the heating rate is 10°C / min, and the temperature is naturally lowered. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, vacuum filter and separate, wash with deionized water for 5 times, and vacuum dry at 100°C for 12 hours. The obtained black powder is boron Doped three-dimensional porous carbon materials. Figure 4 It is a scanning electron micrograph of the boron-doped three-dimensional porous carbon material; it is a three-dimensional porous material. Electrochemical test results show that at 2A g -1 Under the current density, the capacity retention rate is as high as 97% after 1000 cycles.

Embodiment 3

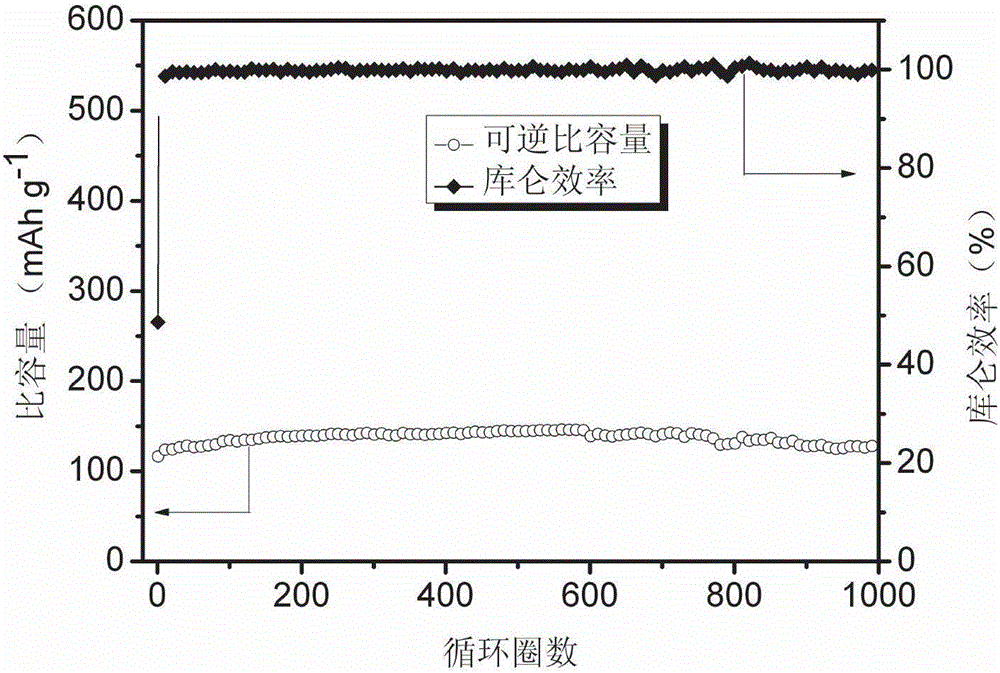

[0042] Mix 0.2g of carbon quantum dots with 1.0g of sodium hydroxide and 1.2g of melamine evenly, and then calcinate them at 1000°C for 2h under the protection of an inert gas, with a heating rate of 15°C / min, and cool down naturally. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, separate it by vacuum filtration, wash it with deionized water for 5 times, and dry it in vacuum at 100°C for 12 hours. The black powder obtained is nitrogen Doped three-dimensional porous carbon materials. Figure 5 It is a scanning electron micrograph of the nitrogen-doped three-dimensional porous carbon material, which is a porous three-dimensional structure. Such as Image 6 As shown, the electrochemical test results show that at 2A g -1 Under the current density, its reversible specific capacity still maintains 117.7mAh g after 1000 charge-discharge cycles. -1 , The capacity retention rate after 1000 cycles is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com