Phase hunting detection method for permanent magnet planar motor adopting switch Hall array

A permanent magnet plane and detection method technology, applied in the direction of phase sequence/synchronous indication, etc., can solve the problems that the phase relationship between the coil and the permanent magnet array cannot be determined, and the commutation point of the drive unit coil cannot be determined, etc., achieving strong anti-interference ability, No noise accumulation, simple circuit processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

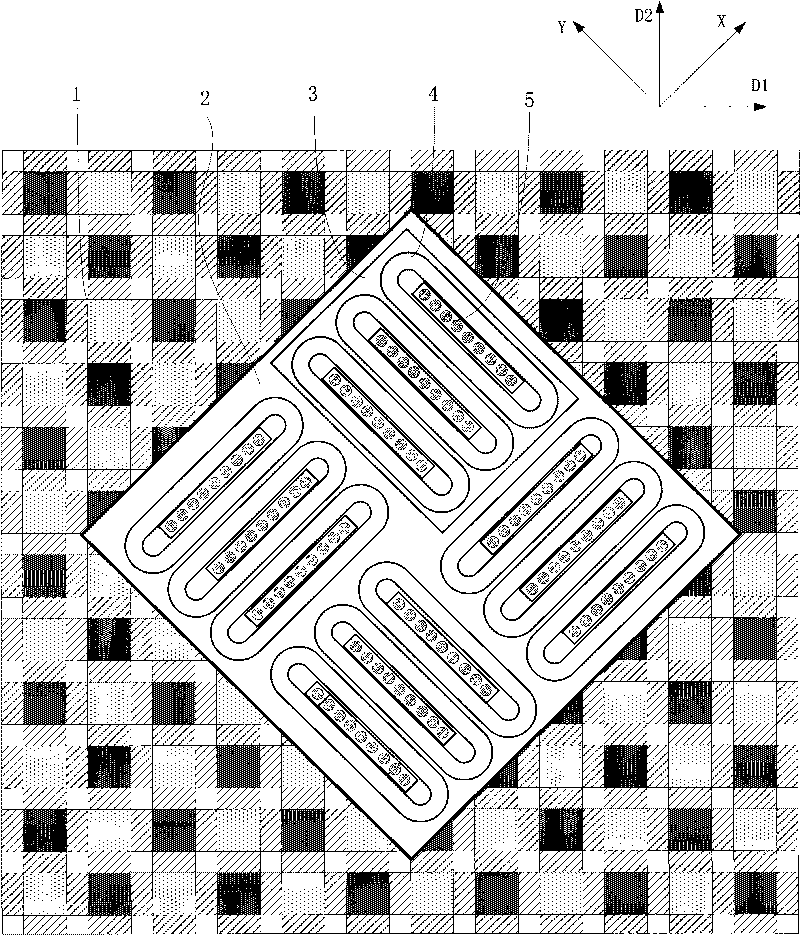

[0025] The present invention provides a permanent magnet planar motor phase-finding detection method using a switch Hall array. The permanent magnet planar motor contains a permanent magnet array and a coil array. The coil array is composed of more than two drive units, each A drive unit is made up of more than two coils, it is characterized in that the method comprises the steps:

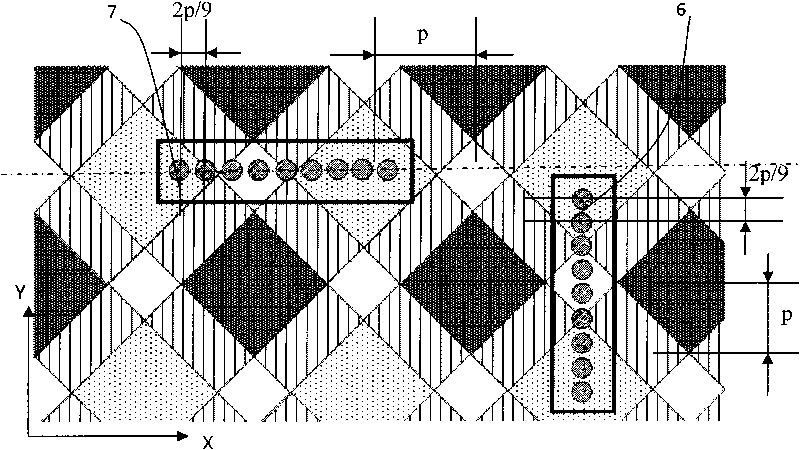

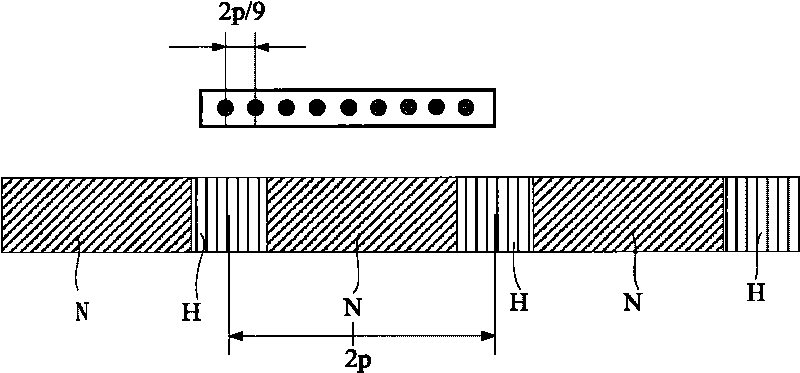

[0026] a. Each coil corresponds to a Hall array, and the Hall array is placed perpendicular to the horizontal output direction of the drive unit where the coil is located. The Hall array is composed of M (M≥3 and odd) switch Hall sensors, The switch hall sensors are distributed at equal intervals within even multiples of the pole distance;

[0027] b. The switch hall sensor is placed in parallel with the permanent magnet array, which is used to measure the magnetic flux density component perpendicular to the moving direction of the planar motor; if the magnetic flux density measured by the switch h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com