Brushless direct current motor counter electromotive force phase point detecting method

A technology of brushed DC motor and counter electromotive force, which is applied in the direction of electronically commutated motor control, electronic commutator, electrical components, etc., can solve the problems of high cost and short freewheeling time, and achieve low cost, high detection reliability, The effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

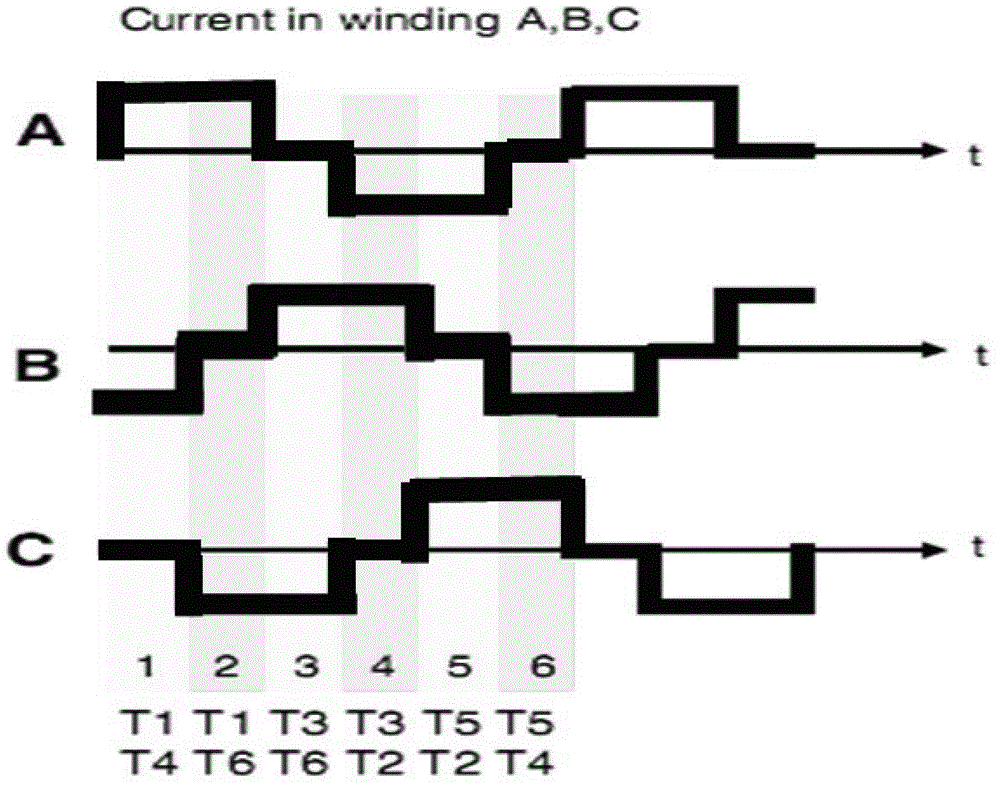

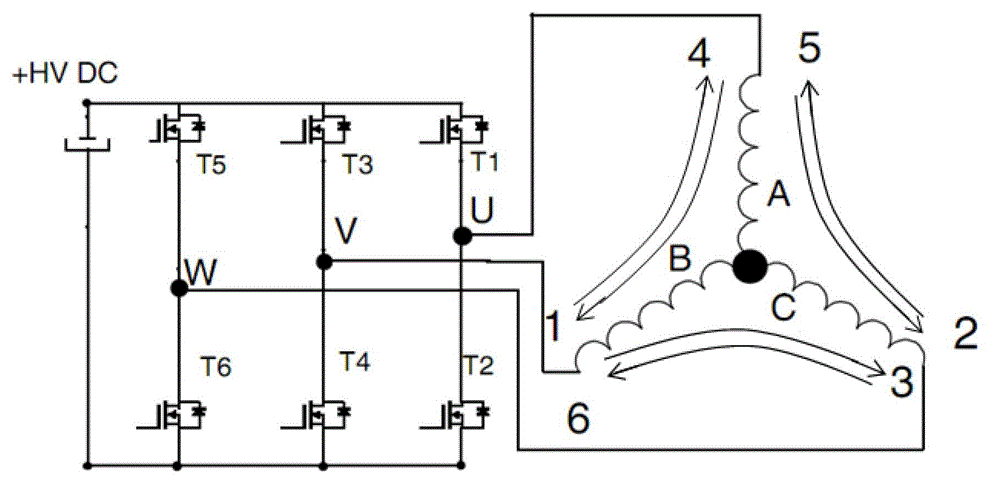

[0018] see Figure 1 to Figure 4 , the brushless DC motor counter electromotive force commutation point detection method, including the following four steps:

[0019] Step 1: Connect the three stator windings of the motor to the control power supply Apply voltage to the three stator windings of the motor so that after each commutation one winding is connected to the positive pole of the control power supply and the second winding is connected to the control power supply and the third is in a de-energized state; that is, the current flows in from the winding connected to the positive pole of the power supply, flows out from the winding connected to the negative pole of the power supply, the third winding is in a de-energized state, and only two of the three phases of the motor A voltage is applied to the phase;

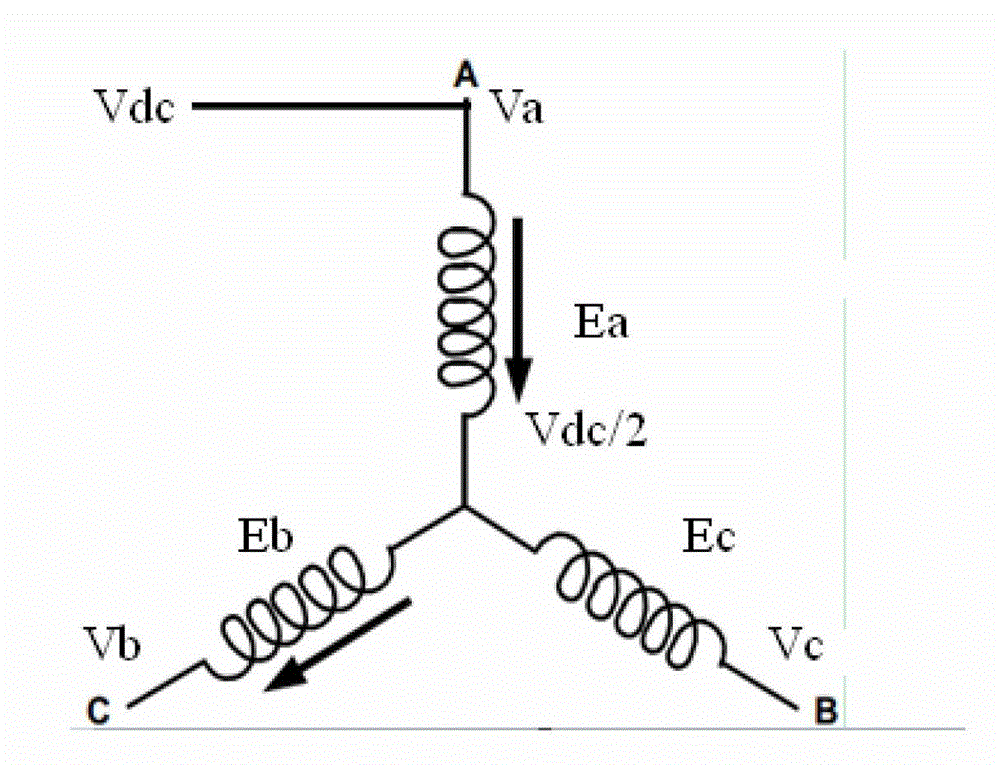

[0020] Step 2: Detect the ground terminal voltages Va, Vb and Vc of the three stator windings, and the counter electromotive force E=(Va+Vb+Vc)-3Vdc / 2; where, Vdc is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com