Forging method for improving TC18 titanium alloy structure property

A microstructure performance, TC18 technology, applied in the field of material processing, can solve the problem of less research on TC18 quasi-β forging, and achieve the effect of improving the reliability of the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1.1 Raw materials

[0021] (1) The chemical composition of raw materials is re-inspected according to the standard GB / T4698, and the result is qualified;

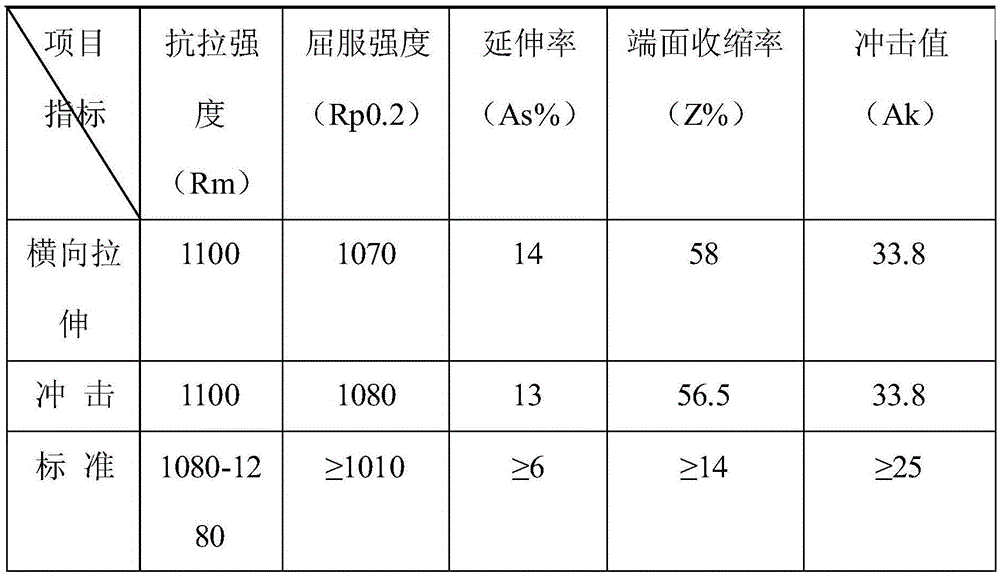

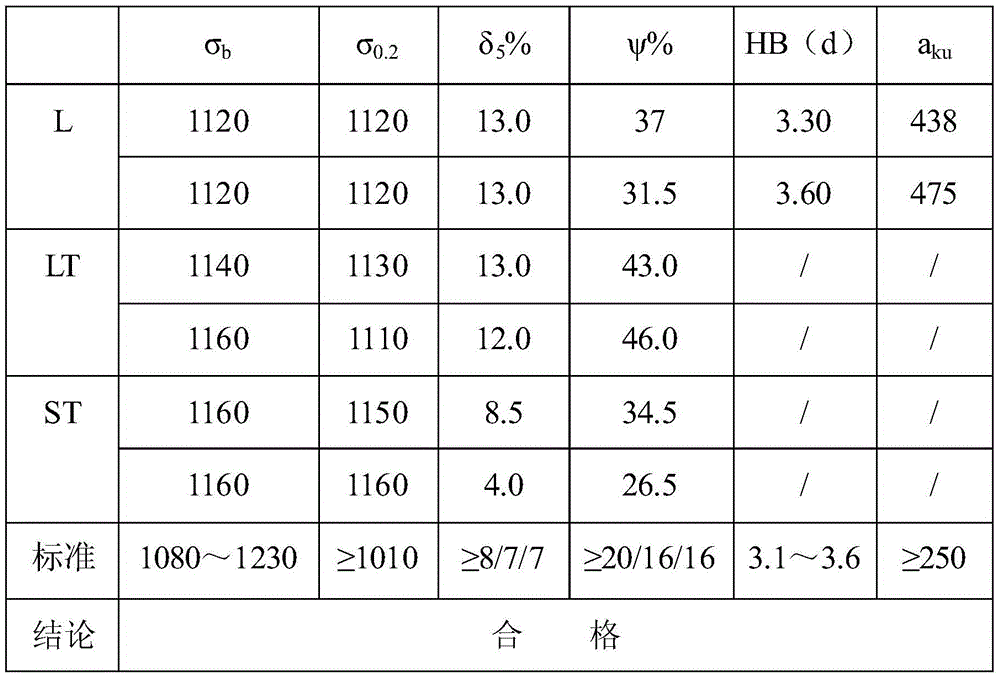

[0022] (2) The mechanical properties of raw materials were re-inspected according to the standard YMS1507, and the result was qualified, as shown in Table 1;

[0023] (3) Low-magnification structure of raw materials: no clear crystals, no metallurgical defects, standard: GB / T5168.

[0024] Table 1 Mechanical Properties of Raw Materials

[0025]

[0026] (4) High-magnification structure of raw materials: uniform equiaxed α structure, standard: GB / T5168;

[0027] (5) Raw material flaw detection: According to Φ2.0 flat-bottomed hole, the result is qualified, standard: Class A in YMS1507;

[0028] (6) Raw material KIC: standard data: ≥55, actual measurement: 59.5-58.6, the result is qualified, standard: YMS1507.

[0029] 1.2 Forging, heat treatment, machining and inspection

[0030] (1) Because the microstructure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com