Reaction device for co-producing low-carbon olefin and p-xylene

A technology for p-xylene and low-carbon olefins, which is applied in the field of reaction devices for the co-production of low-carbon olefins and p-xylene, and can solve the problems of low yield of low-carbon olefins and p-xylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

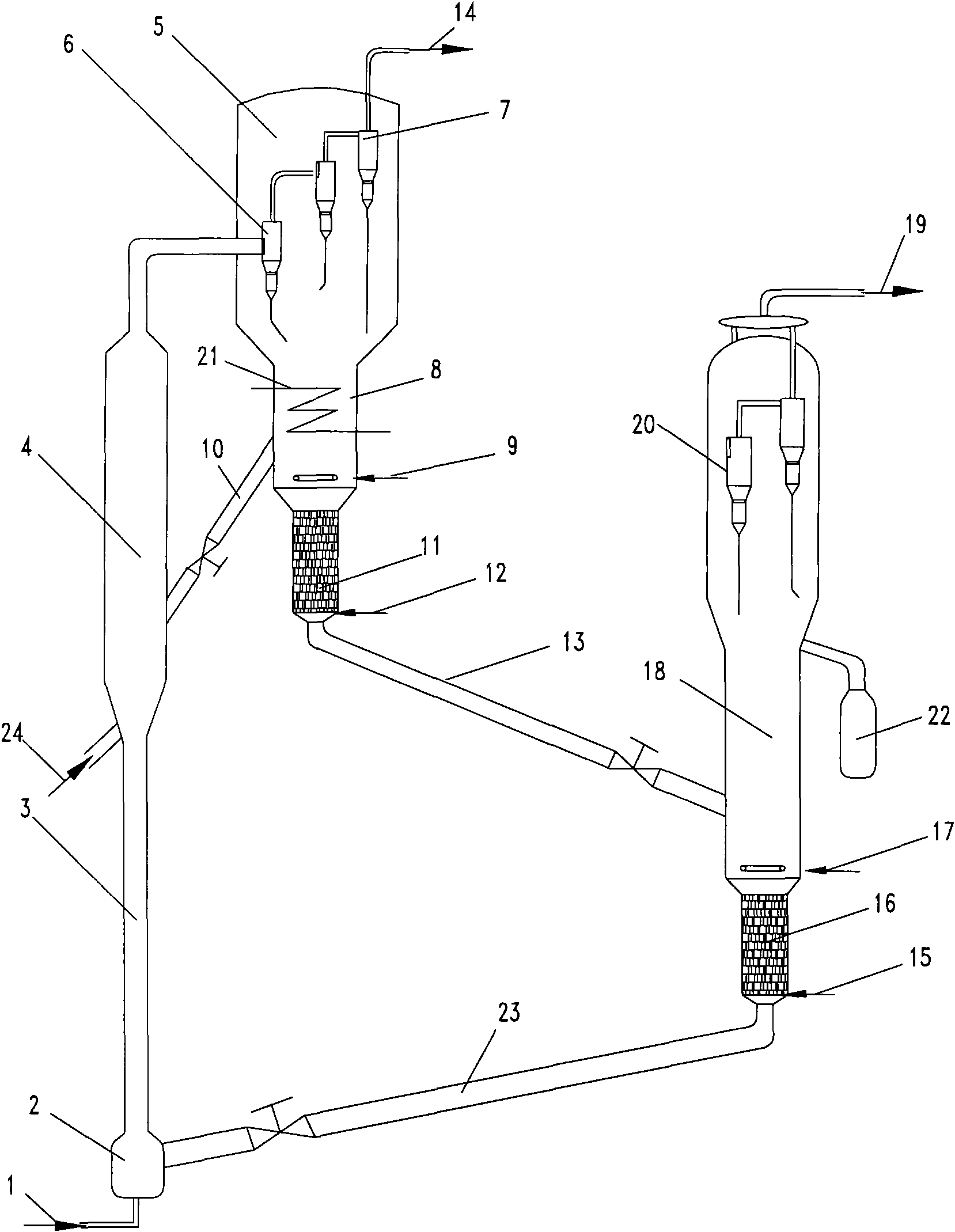

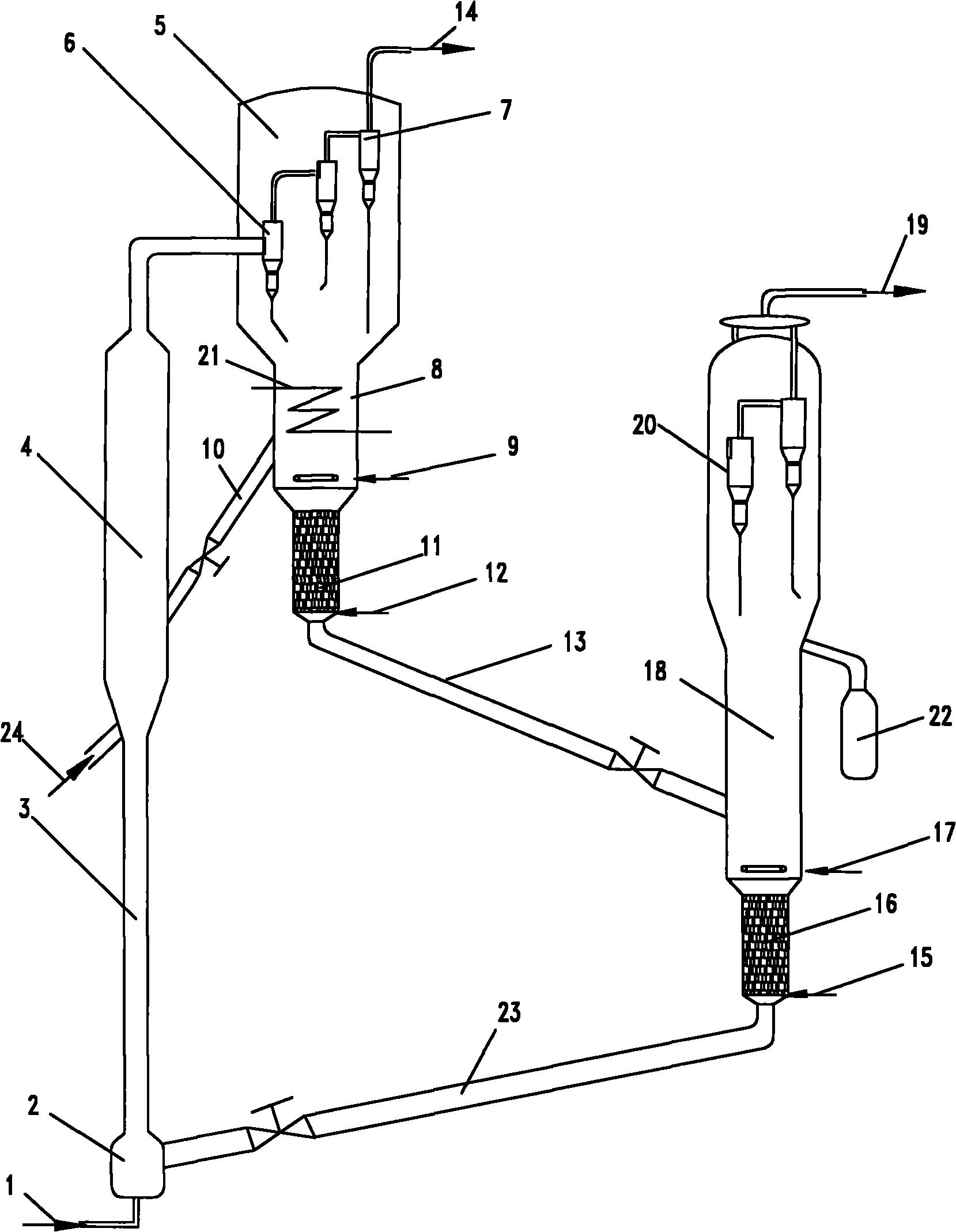

[0031] in such as figure 1 On the reaction device shown, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 20, the first raw material enters the first reaction zone, and contacts with the catalyst, wherein the first raw material includes 60% carbon four mixed hydrocarbons, 26% carbon five mixed hydrocarbons, and the rest is water vapor. 4. C5 mixed hydrocarbons are by-products of methanol conversion. The gas phase stream and catalyst generated in the first reaction zone enter the second reaction zone and contact with the second raw material comprising methanol and toluene, wherein the weight ratio of methanol to toluene in the second raw material is The mass flow rate of the second raw material is 1:5, and the mass flow rate of the second raw material is 2 kg / hour. The gas-phase stream and the catalyst generated in the second reaction zone are separated by the gas-solid rapid separation equipment and then enter the gas-solid separation zone. The separated gas-phase s...

Embodiment 2

[0033] According to the conditions and steps described in Example 1, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 200, the first raw material enters the first reaction zone, and contacts with the catalyst, wherein the first raw material includes 48% carbon four mixed hydrocarbons, 37% carbon five mixed hydrocarbons, and the rest is water vapor. 4. C5 mixed hydrocarbons are by-products of methanol conversion. The gas phase stream and catalyst generated in the first reaction zone enter the second reaction zone and contact with the second raw material comprising methanol and toluene, wherein the weight ratio of methanol to toluene in the second raw material is The mass flow rate of the second raw material is 1:3, and the mass flow rate of the second raw material is 2.7 kg / h. The gas-phase stream and the catalyst generated in the second reaction zone enter the gas-solid separation zone after being separated by the gas-solid rapid separation equipment, and the separat...

Embodiment 3

[0035] According to the conditions and steps described in Example 1, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 100, the first raw material enters the first reaction zone, and contacts with the catalyst, wherein the first raw material includes 54% carbon four mixed hydrocarbons, 31% carbon five mixed hydrocarbons, and the rest is water vapor. 4. C5 mixed hydrocarbons are by-products of methanol conversion. The gas phase stream and catalyst generated in the first reaction zone enter the second reaction zone and contact with the second raw material comprising methanol and toluene, wherein the weight ratio of methanol to toluene in the second raw material is The mass flow rate of the second raw material is 1:2, and the mass flow rate of the second raw material is 2 kg / h. The gas-phase stream and the catalyst generated in the second reaction zone are separated by the gas-solid rapid separation equipment and then enter the gas-solid separation zone. The separated ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com