Dual-phase steel sheet excellent in stretch flange formability and production method thereof

a technology of stretch flange and double-phase steel, which is applied in the field of double-phase sheet plates, can solve the problems of poor stretch flange formability, difficult to obtain high ductility (high elongation), and difficult to obtain bh property above a certain level, so as to improve strength, improve product quality, and improve spot weldability remarkably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

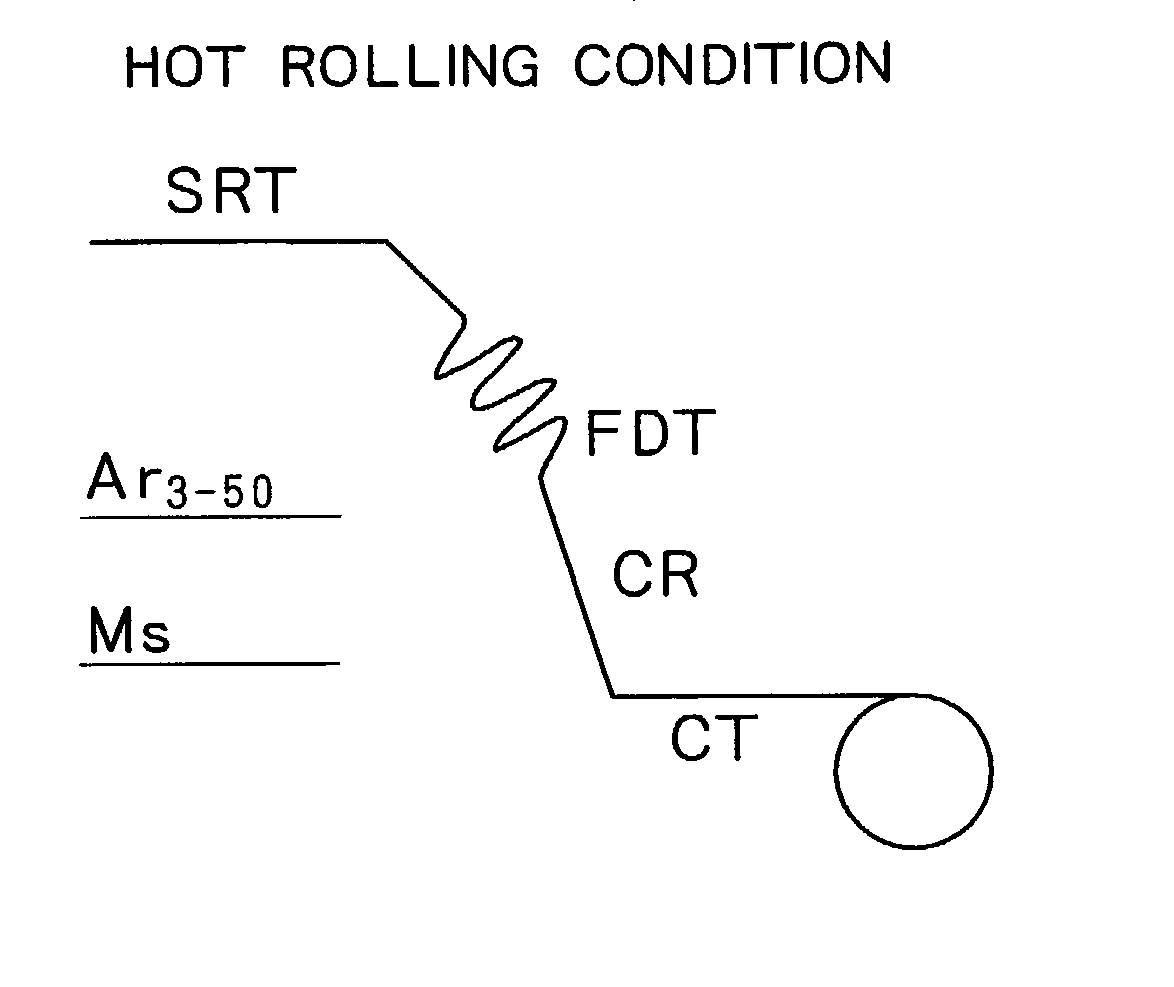

Method used

Image

Examples

example 2

Production Conditions

[0207] In this example, steel sheets having various structures shown as Nos. 1-9 in Table 3 were obtained by using the experimental slab No. 2 in Table 1 and conducting production under various production conditions shown in Table 3. The sheet thickness was 1.2 mm for all of the sheets except for the hot rolled steel sheet No. 9 (2.0 mm) in Table 3.

[0208] Then, structures and various characteristics of the steel sheets were examined in the same manner as in Example 1. The results are shown in Table 4.

3 TABLE 3 Cold rolling Continuous Continuous annealing or galvanization Hot rolling Cold rolling annealing Zn.fwdarw.G SRT FDT CR CT ratio T1 CR T2 T3 t3 CR T4 t4 A Steel Desired No. .degree. C. .degree. C. .degree. C. / s .degree. C. % .degree. C. .degree. C. / s .degree. C. .degree. C. sec .degree. C. / s .degree. C. sec .degree. C. species structure Hot rolling 1 1150 850 40 550 50 900 20 200 800 60 10 460 10 550 GA TM100% cold rolling.fwdarw. First contin- 2 1150 850 ...

example 3

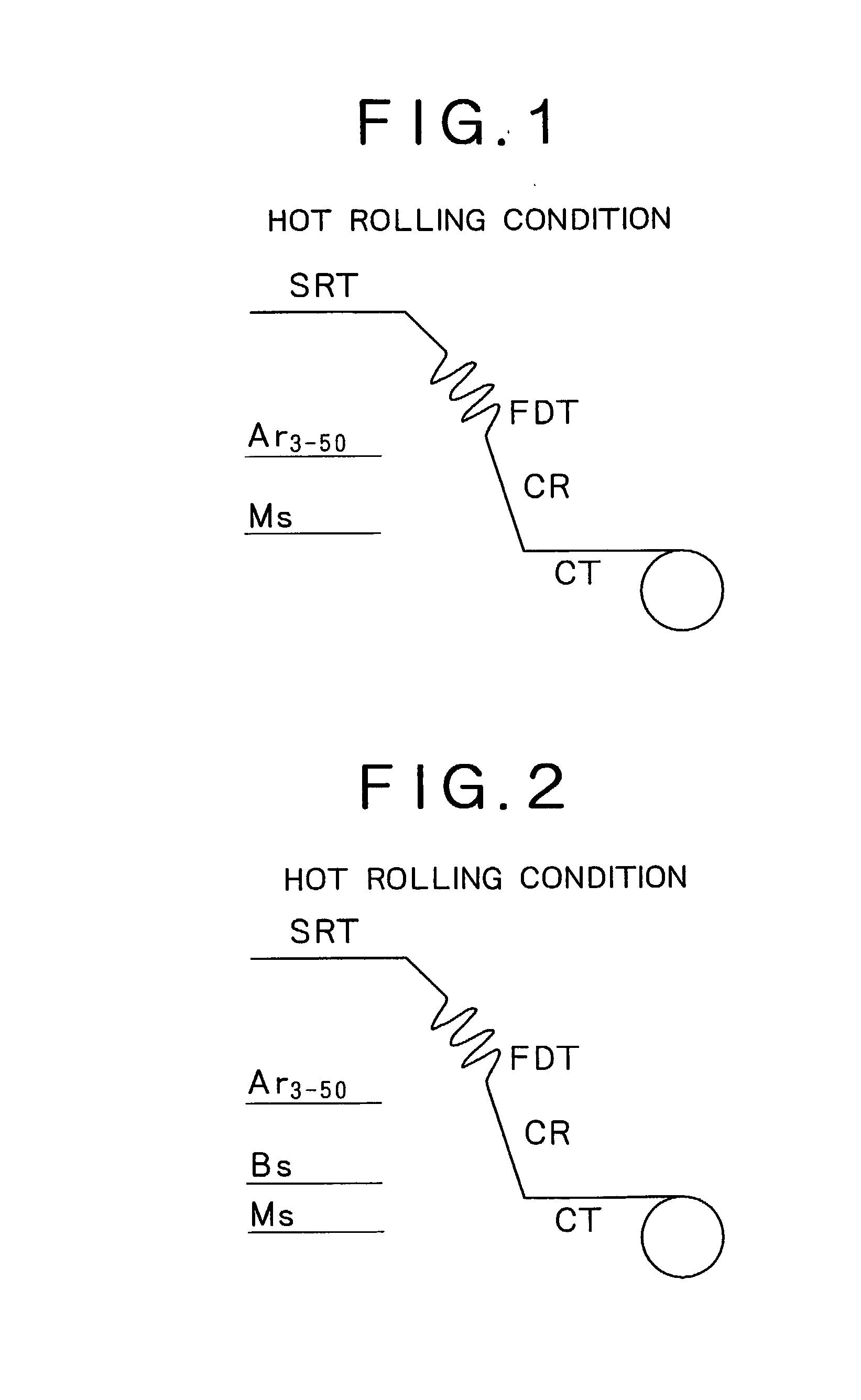

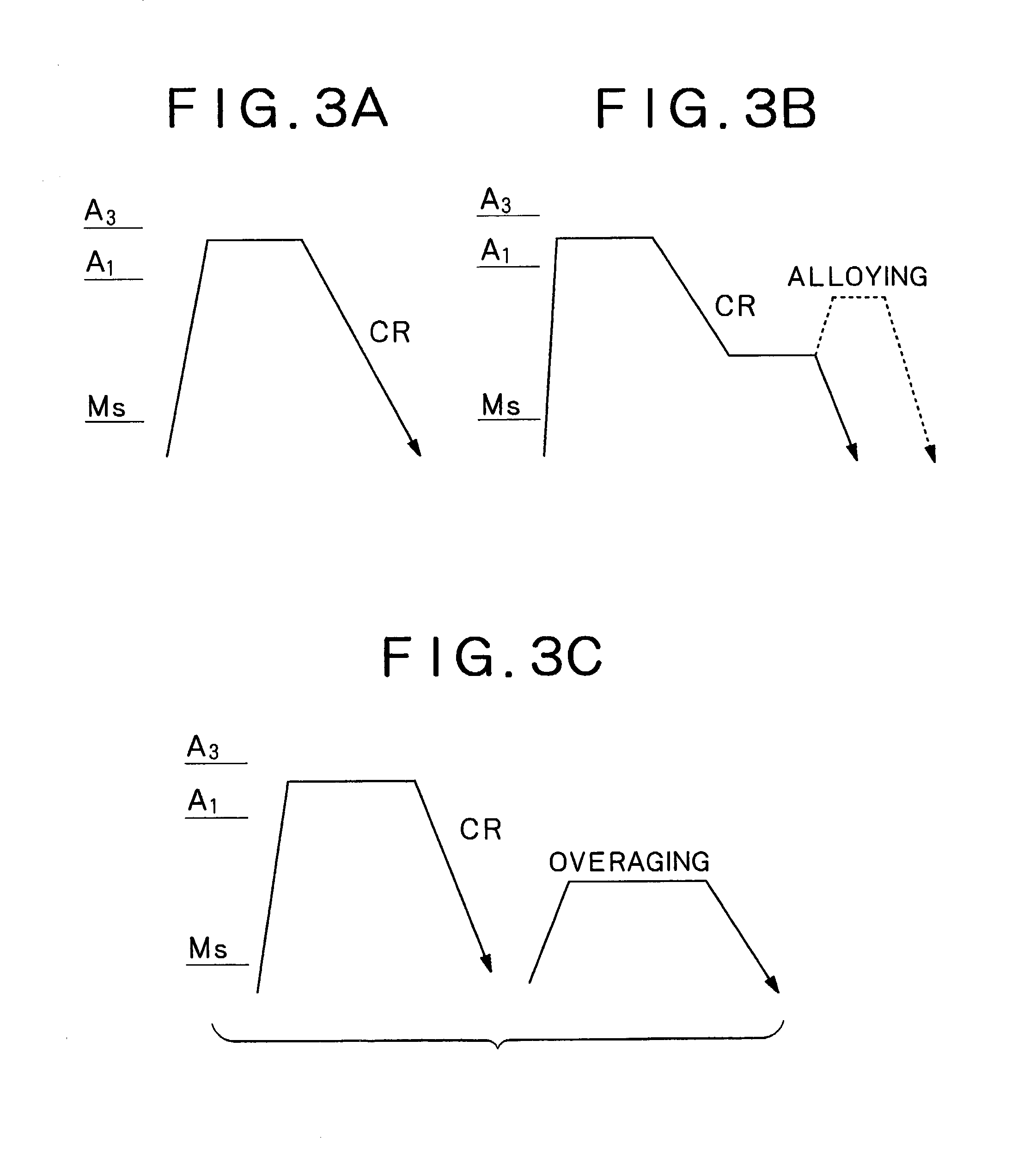

[0215] Various kinds of steel sheets were produced by using test steels No. 1-19 satisfying the chemical compositions shown in Table 5 and applying heat treatment under the conditions shown in Table 6 of Table 8. In Table 6, (1)-(4) described in the column "production step" correspond, respectively, to the methods (1)-(4) described previously. That is, the method (1) is a method of producing a steel sheet having a matrix phase comprising tempered martensite or tempered bainite by way of hot rolling step.fwdarw.continuous annealing or galvanization step; the method (2) is a method of producing a steel sheet having a matrix phase comprising tempered martensite or tempered bainite by way of hot rolling step.fwdarw.cold rolling step.fwdarw.first continuous annealing step.fwdarw.second continuous annealing or galvanization step; the method (3) is a method of producing a steel sheet having a matrix phase comprising a mixed structure of (tempered martensitic and ferrite) or tempered bainit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com