Continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles

A technology with high tensile strength and low yield, applied in the field of metal material processing, can solve the problems of low tensile strength, poor formability, poor aging resistance, high yield strength, etc., achieve low yield ratio, high formability, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

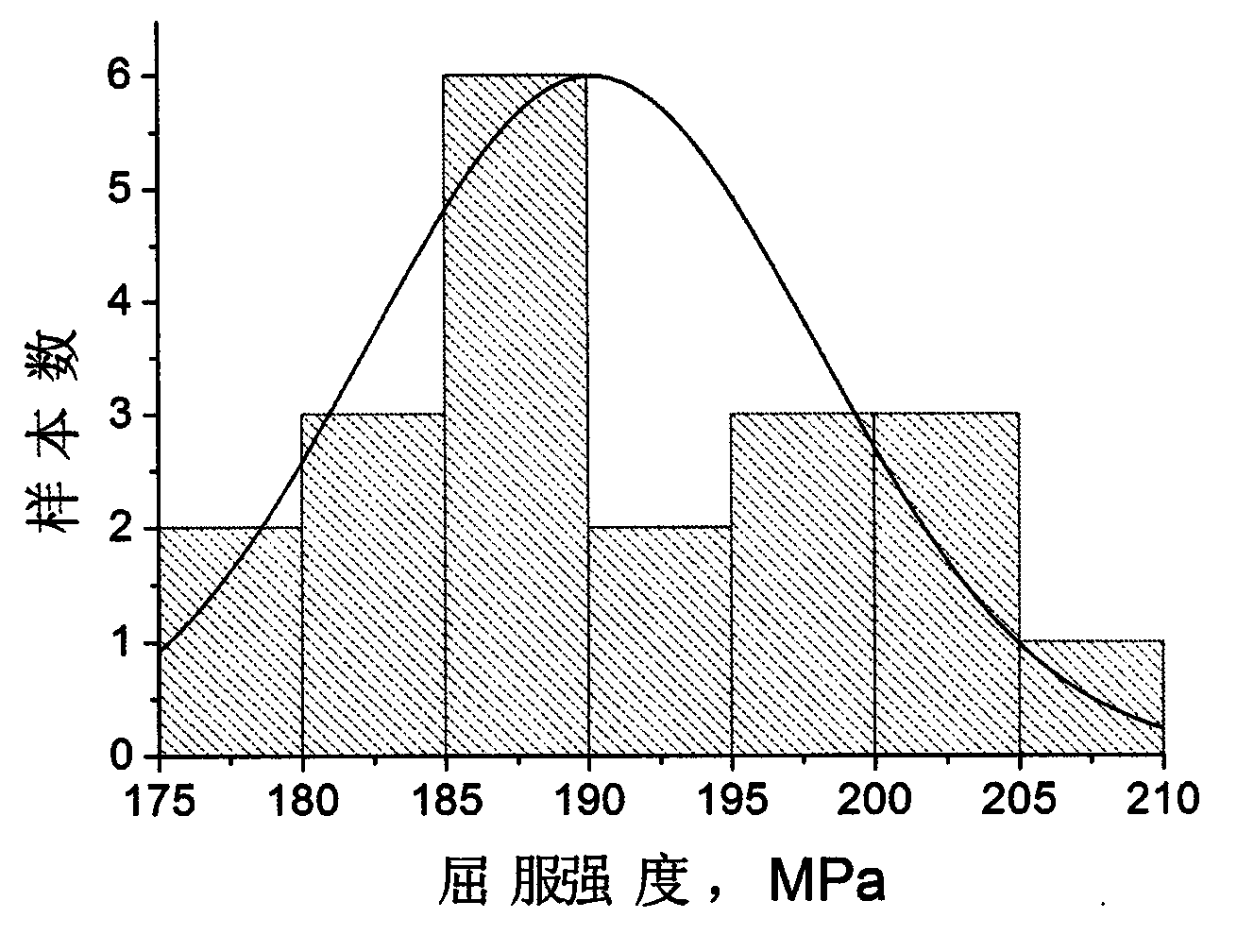

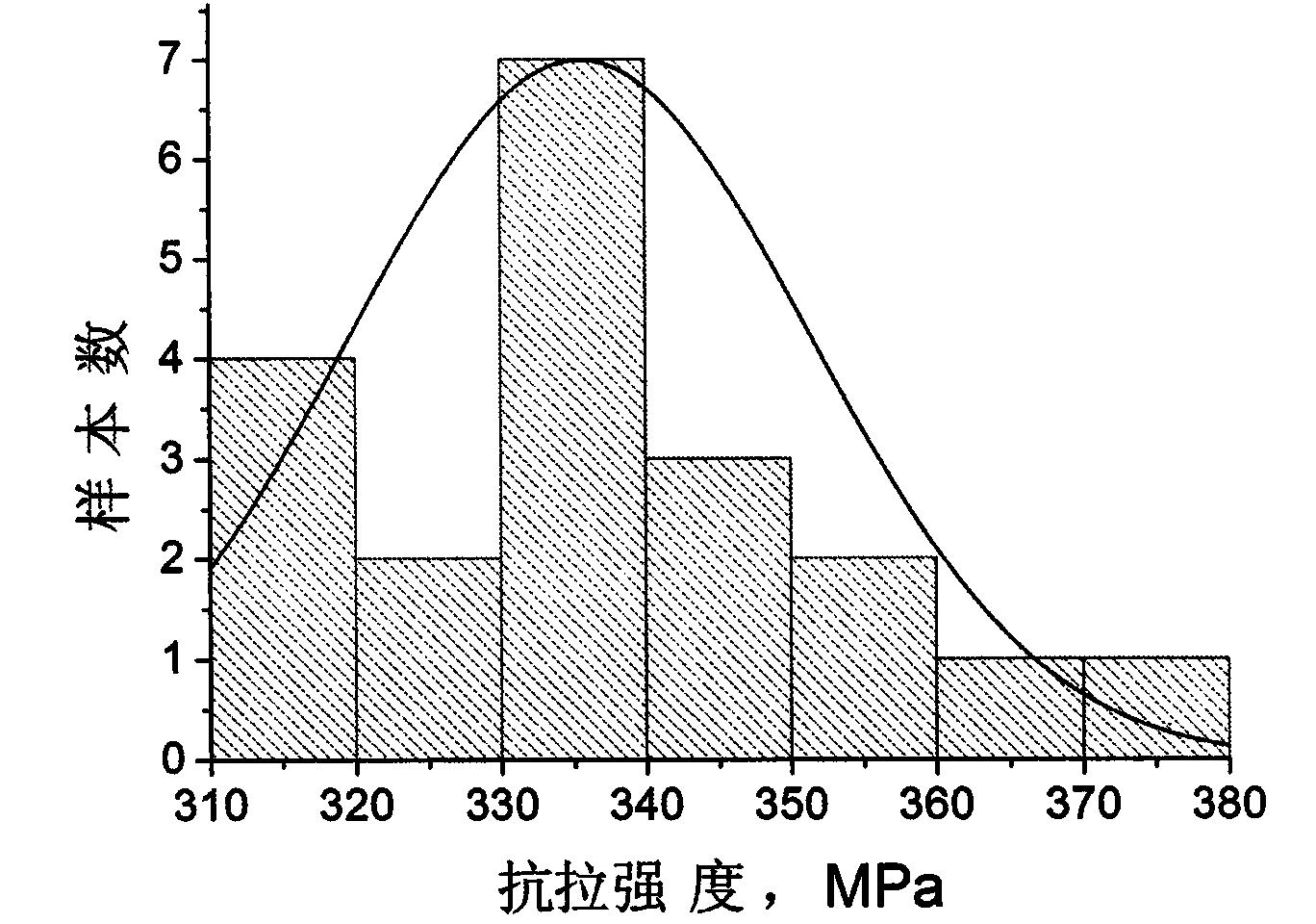

[0024] In the following are the mechanical properties of the continuously annealed products manufactured according to the method (including chemical composition and process) described in the present invention. It can be seen that by adjusting the coiling temperature of hot rolling and adopting appropriate annealing process parameters, the mechanical properties of the production can meet the performance requirements of stamping and forming of automobile sheets.

[0025] Preface

[0026] Steel plate specification: 0.8×1250mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com