Hydraulic multi-time switching circulating valve

A switch circulation and hydraulic technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of screw drilling tool damage, increased sticking, low debris flowback capacity, etc., to achieve The effect of improving flowback capacity, increasing flushing displacement, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

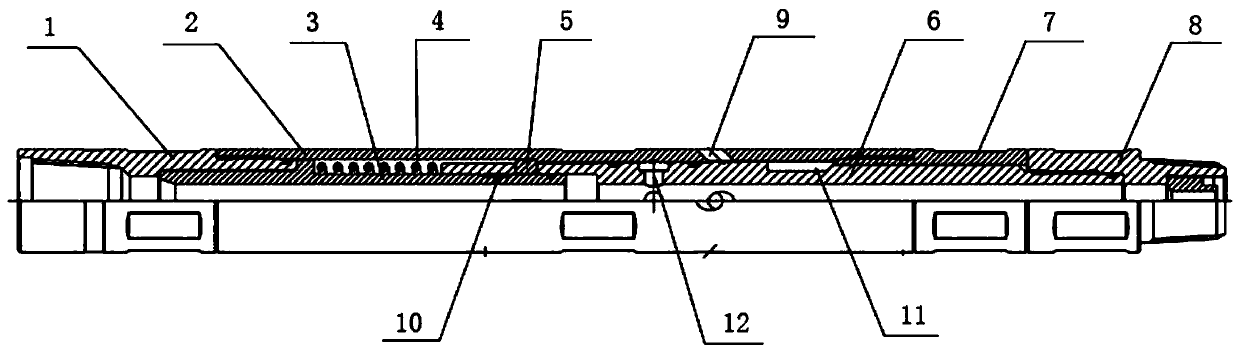

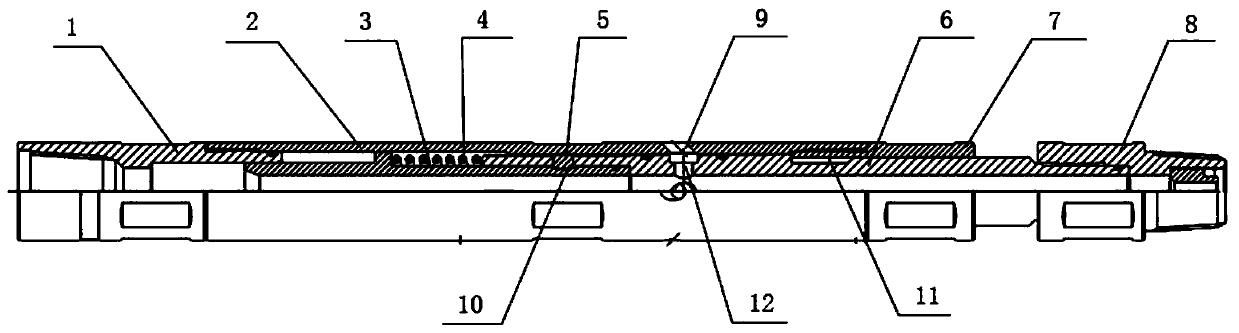

[0018] Such as Figures 1 to 2 As shown, a hydraulic multiple switch cycle valve includes a first joint 1, a housing 2, a first mandrel 3, a compression spring 4, a block 5, a second mandrel 6, a second joint 7, a second Three joints 8 and nozzles, the housing 2 is provided with a channel 9, the left end of the housing 2 is threaded with the first joint 1, the right end is threaded with the second joint 7, and the left end of the first mandrel 3 is provided with The first shoulder, the right end is provided with a first limit groove 10, and the outer surface of the right end of the first mandrel 3 is in contact with the inner surface of the left end of the second mandrel 6, and the first mandrel 3 and the second mandrel 6 are in common Placed inside the shell 2, and the outer surface of the left end of the first mandrel 3 is in contact with the inner surface of the first joint 1, the outer surface of the first shoulder is in contact with the inner surface of the shell 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com