Oil drilling system with drilling fluid in and out

A technology of oil drilling and drilling fluid, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc. It can solve problems such as wellbore instability, difficulty, wellbore collapse and block, and improve flowback capacity , The effect of promoting and avoiding material exchange during the drilling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

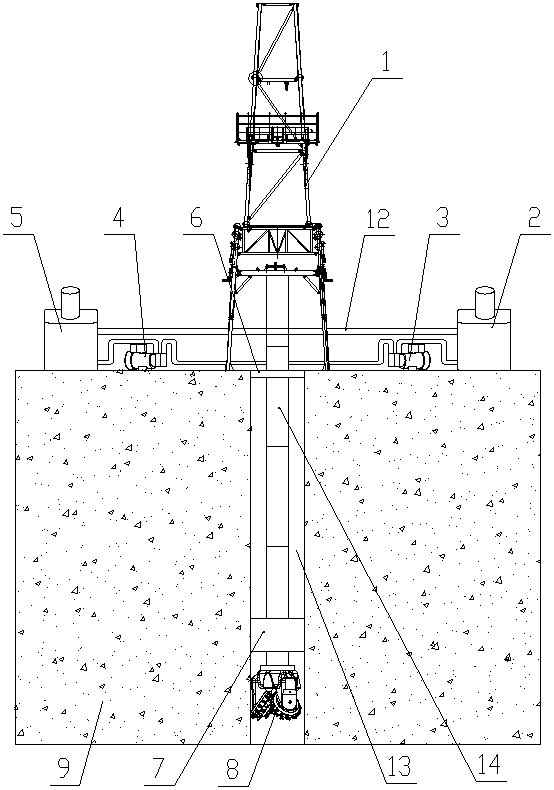

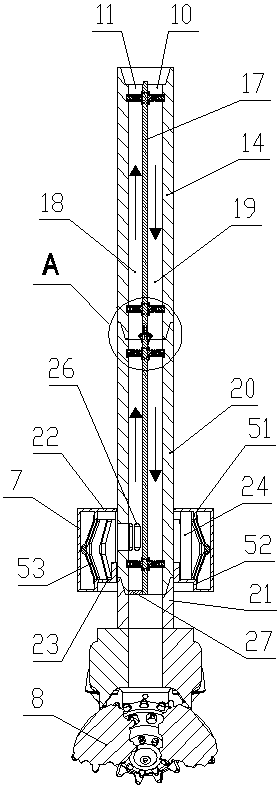

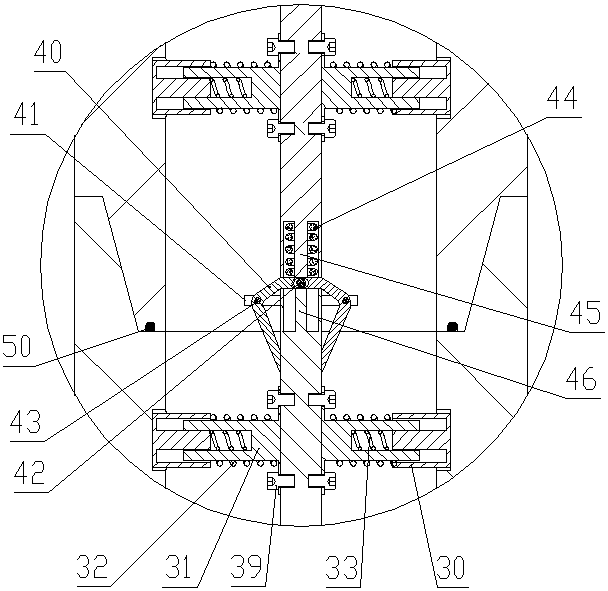

[0032] Such as Figure 1 to Figure 8 shown in figure 2 The left side is the left side of the present invention, figure 2 The direction of the arrow in the figure is the flow direction of the drilling fluid. The oil drilling system of the present invention includes a drilling derrick 1, a drilling fluid inlet tank 2, a drilling fluid booster pump 3, a drilling fluid recovery pump 4, a drilling fluid Liquid recovery tank 5, wellhead blowout preventer 6, drill pipe assembly, formation sealing cylinder 7 and drill bit 8;

[0033]Drilling derrick 1, drilling fluid inlet tank 2, drilling fluid booster pump 3, drilling fluid recovery pump 4 and drilling fluid recovery tank 5 are all fixed on the surface of formation 9. Drilling derrick 1 is provided with a power drive mechanism, and drilling fluid inlet The tank 2, the drilling fluid booster pump 3 and the liquid inlet end 10 of the drill pipe assembly are connected sequentially along the flow direction of the drilling fluid thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com