Demulsification cleanup additive for fracturing and preparation method thereof

A demulsification aid and fracturing technology, which is used in the preparation of ether, the preparation of ether from alkylene oxide, chemical instruments and methods, etc. Effectively reduce surface tension and interfacial tension, and achieve the effect of improving flowback effect, easy industrial production and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

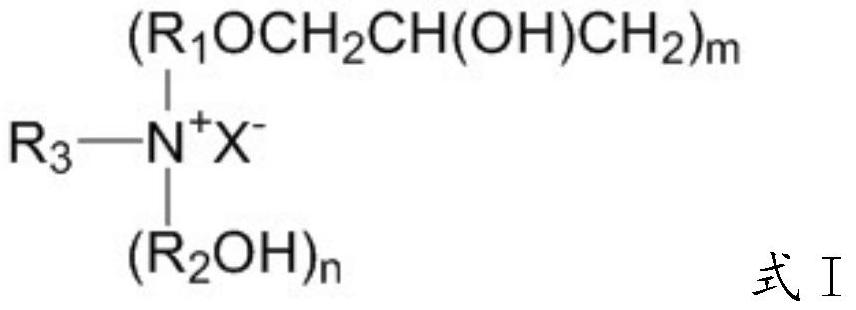

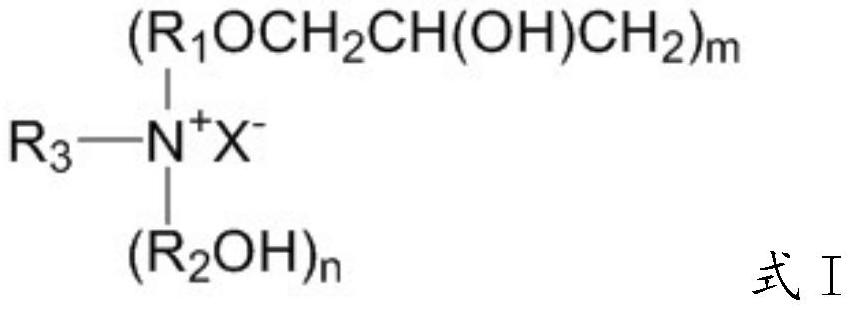

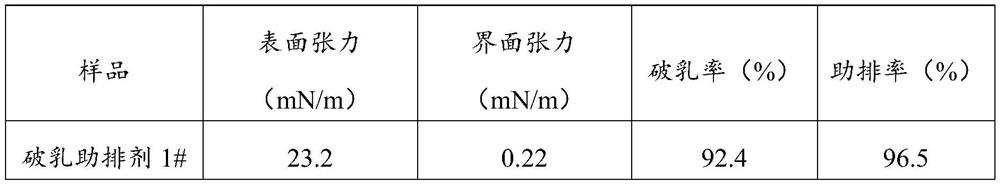

[0033] Embodiment 1 Demulsification aid drainage agent 1#

[0034] The demulsification aid drainage agent 1# for fracturing comprises the following components in percentage by weight: the alkanolamine compound shown in formula I (R 1 for C18, R 2 for C2, R 3 H, m is 1, n is 2, X is CI) 18wt%, C18 fatty acid polyoxyethylene ether sulfonate (the degree of polymerization of polyoxyethylene ether is 5) 16wt%, C12 alkyl glycoside 12wt%, isopropyl Alcohol 8wt% and 46wt% water.

[0035] The preparation method of demulsification aid drainage agent 1# for fracturing comprises the steps:

[0036] (1) Preparation of alkanolamine compounds shown in formula I:

[0037] ① Add 270.5g of stearyl alcohol and cyclohexane into a four-necked bottle, place the four-necked bottle in a constant temperature water bath and heat it up to 60°C, start adding epichlorohydrin dropwise, and continue the reaction for 1 hour after the dropwise addition; then lower When the temperature reaches 40°C, add a...

Embodiment 2

[0040] Embodiment 2 demulsification aid drainage agent 2#

[0041] The demulsification aid drainage agent 2# for fracturing comprises the following components in percentage by weight: the alkanolamine compound (R 1 for C16, R 2 for C2, R 3C2, m is 2, n is 1, X is Br) 20wt%, C12 fatty acid polyoxyethylene ether sulfonate (the degree of polymerization of polyoxyethylene ether is 10) 10wt%, C18 alkyl glycoside 15wt%, ethanol 5wt% % and 50wt% water.

[0042] The preparation method of demulsification aid drainage agent 2# for fracturing comprises the following steps:

[0043] (1) Preparation of alkanolamine compounds shown in formula I:

[0044] ① Add 242.5g of cetyl alcohol and cyclohexane into a four-necked bottle, place the four-necked bottle in a constant temperature water bath and heat it up to 55°C, start adding epichlorohydrin dropwise, and continue the reaction for 1.5h after the dropwise addition; then Lower the temperature to 35°C, add aqueous sodium hydroxide soluti...

Embodiment 3

[0047] Embodiment 3 demulsification aid drainage agent 3#

[0048] The demulsification aid drainage agent 3# for fracturing comprises the following components in percentage by weight: the alkanolamine compound (R 1 for C12, R 2 for C3, R 3 C3, m is 2, n is 1, X is Br) 10wt%, C16 fatty acid polyoxyethylene ether sulfonate (the degree of polymerization of polyoxyethylene ether is 9) 20wt%, C14 alkyl glycoside 5wt%, isopropyl Alcohol 10wt% and 55wt% water.

[0049] The preparation method of demulsification aid drainage agent 3# for fracturing comprises the steps:

[0050] (1) Preparation of alkanolamine compounds shown in formula I:

[0051] ① Add 186.4g of dodecanol and cyclohexane into a four-necked bottle, place the four-necked bottle in a constant temperature water bath and heat it up to 80°C, start adding epichlorohydrin dropwise, and continue the reaction for 1 hour after the dropwise addition; then lower When the temperature reaches 50°C, add sodium hydroxide aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com