Method for preparing hydrocracking catalyst

A technology for catalyst and hydrogenation activity, applied in the field of preparation of hydrocracking catalysts, can solve the problems of low utilization rate of metals, limitation of metal content in preparation of catalysts, limitation of pore structure of catalysts, etc., so as to reduce the phenomenon of capillary resistance, low cost, A stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

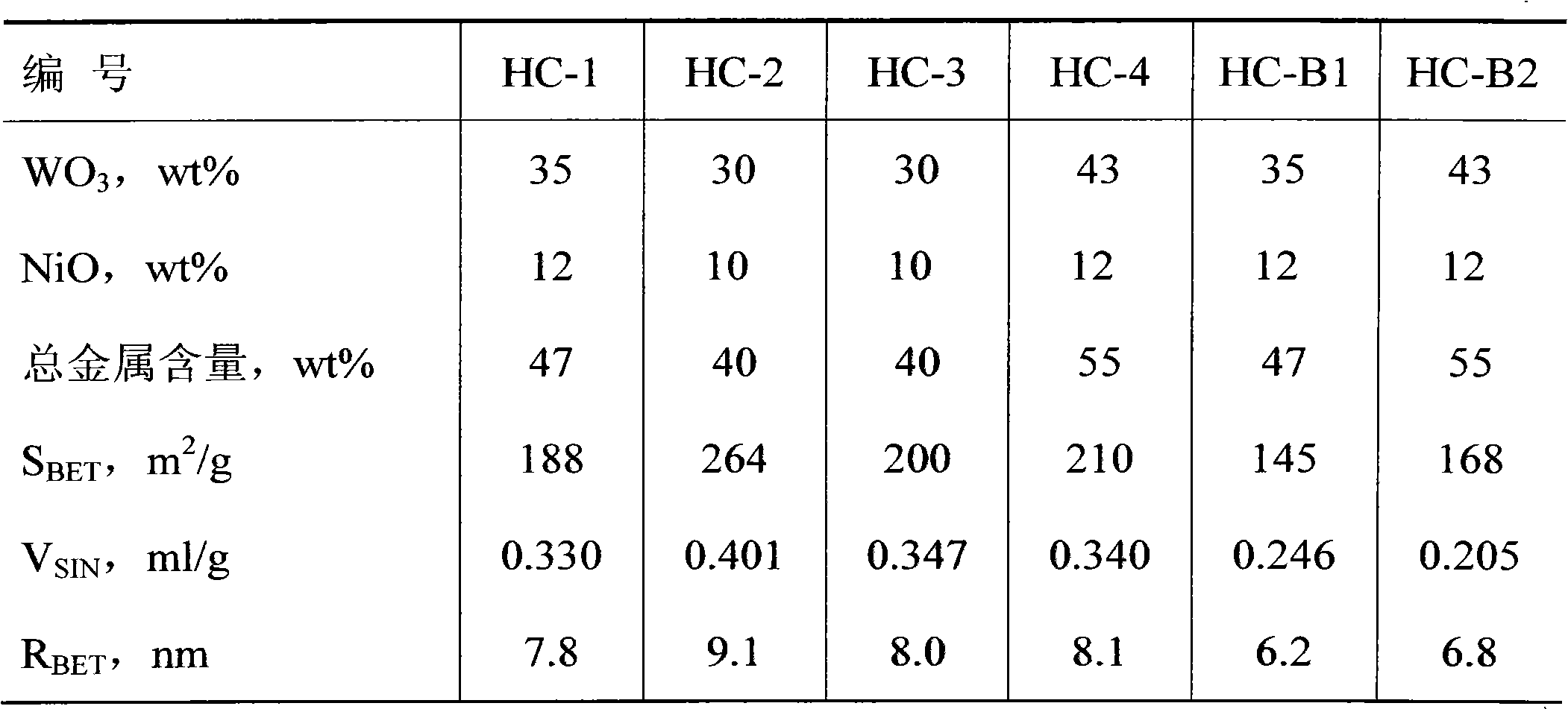

Embodiment 1

[0031] According to the weight of the final hydrocracking catalyst, it contains 15% of Y molecular sieve, 25% of amorphous silicon aluminum, 12% of nickel oxide, 35% of tungsten oxide, and the balance is aluminum oxide. , Aluminum hydroxide dry rubber powder 1 and amorphous silica-alumina dry rubber powder 1.

[0032] The catalyst preparation process is as follows: fully mix Y molecular sieve, aluminum hydroxide dry rubber powder and amorphous silica-alumina dry rubber powder, mix with the prepared solution containing nickel and tungsten compounds for hydrogenation components, impregnate and beat for 120 minutes, and suction filter , dried at 120°C for 4 hours, then pulverized, and sieved with 180 mesh to obtain a powder. Mix the powder with an appropriate amount of extrusion aid, scallop powder, and add a concentration of 4gHNO 3 / 100ml dilute nitric acid for peptization, extruded into a clover strip with a diameter of 1.5mm. Then it was dried at 120°C for 4 hours and calci...

Embodiment 2

[0034] According to the weight of the final hydrocracking catalyst, it contains 25% of Y molecular sieve, 10% of amorphous silicon aluminum, 10% of nickel oxide, 30% of tungsten oxide, and the balance is alumina. , Aluminum hydroxide dry rubber powder 1 and amorphous silica-alumina dry rubber powder 2.

[0035] The preparation method is the same as in Example 1, and the obtained catalyst number is HC-2.

Embodiment 3

[0037] According to the weight of the final hydrocracking catalyst, it contains 30% of Y molecular sieve, 10% of amorphous silica-alumina, 10% of nickel oxide, 30% of tungsten oxide, and the balance is alumina. , Aluminum hydroxide dry rubber powder 2 and amorphous silica-alumina dry rubber powder 1.

[0038] The preparation method is the same as in Example 1, and the obtained catalyst number is HC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com