Composite acid liquid system for weak heterogeneous reservoir acidification and preparation method of composite acid liquid system

A heterogeneous, compound acid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as formation damage, and achieve the effects of avoiding waste, slowing acidification, and slowing down the time of water breakthrough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

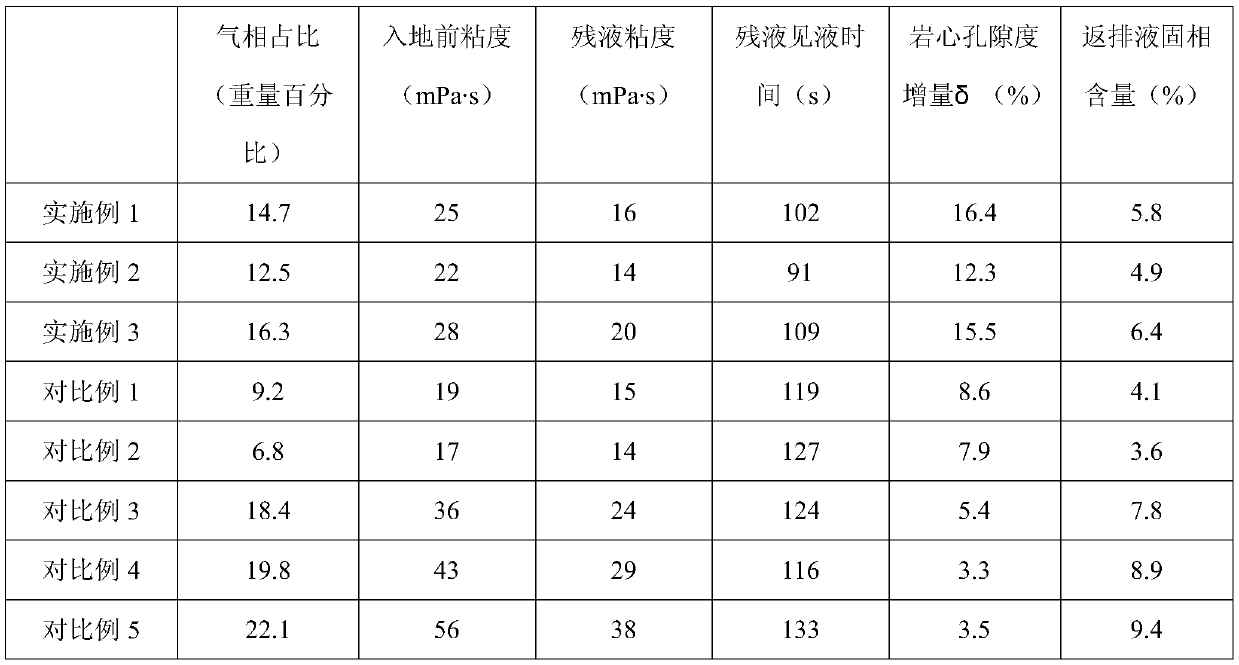

Examples

Embodiment 1

[0023] A compound acid solution system for acidizing weakly heterogeneous reservoirs, including the following components in mass percentage: 1% gelling agent, 0.4% thickening agent, 5% corrosion inhibitor, 1.5% drainage aid, iron 1% ion stabilizer, 4% blowing agent, 0.3% foam stabilizer, 1% calcium carbonate, 15% hydrochloric acid, and the balance is water.

[0024] Preferably, the gelling agent is a copolymer formed of methacryloxyethyltrimethylammonium chloride and acrylamide. The thickener is a copolymer formed of anionic monomer 2-acrylamide-2-methylpropanesulfonic acid and acrylamide. The corrosion inhibitor is Mannich base quaternary ammonium salt. The concentration of hydrochloric acid is 25%.

[0025] The preparation method of the compound acid liquid system in this embodiment is as follows: mix the components according to the mass percentage, and stir with a high-speed mixer at a speed of 1800 rpm to 2000 rpm until a milky white uniformly dispersed microfoam liquid ...

Embodiment 2

[0027] A compound acid system for acidizing weakly heterogeneous reservoirs, including the following components in mass percentage: 0.8% gelling agent, 0.4% thickening agent, 5% corrosion inhibitor, 1.5% drainage aid, iron 1% of ion stabilizer, 3% of foaming agent, 0.2% of foam stabilizer, 1% of calcium carbonate, 15% of hydrochloric acid, and the balance is water.

Embodiment 3

[0029]A compound acid solution system for acidizing weakly heterogeneous reservoirs, including the following components in mass percentage: 1.2% gelling agent, 0.3-0.5% thickening agent, 5% corrosion inhibitor, and 1.5% drainage aid , 1% iron ion stabilizer, 5% foaming agent, 0.2% foam stabilizer, 1% calcium carbonate, 15% hydrochloric acid, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com