Lubricating grease containing carbon nanotubes and preparation method of lubricating grease

A technology of carbon nanotubes and lubricating grease, which is applied in the field of lubricating grease containing carbon nanotubes and its preparation, can solve the problems of lubricating grease anti-wear performance and high temperature resistance performance, etc. The effect of anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

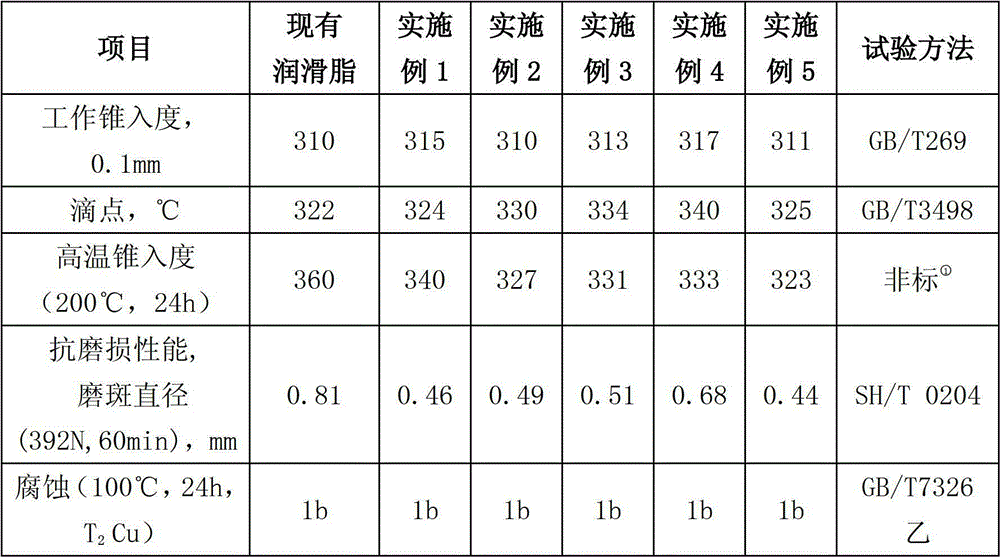

Examples

Embodiment 1

[0026] Put 24g of treated multi-walled carbon nanotubes and 1080g of paraffin-based mineral base oil into a stirred tank, raise the temperature to 90-100°C under high-speed stirring, and stir at this temperature for 0.5h at high speed. Then reduce the stirring speed, slowly add 60g of organic bentonite, and stir for 20-30 minutes to completely wet the organic bentonite. After the contents of the kettle form a pre-gel, add 36g of propylene carbonate, continue stirring at a high speed for 30-40min, and carry out cyclic shearing until the contents of the kettle form a black and uniform paste-like structure of lubricating grease. During this process, the temperature in the kettle was kept at 80-90°C. Finally, the contents of the kettle are ground by a colloid mill to obtain the finished product.

[0027] The material ratio is described as follows:

[0028] Organic bentonite: 5%;

[0029] Refined paraffinic mineral base oil: 90%;

[0030] Multi-walled carbon nanotubes: 2%;

[...

Embodiment 2

[0033] Put 6g of treated multi-walled carbon nanotubes and 600g of naphthenic mineral base oil into a stirring tank, raise the temperature to 90-100°C under high-speed stirring, and stir at this temperature for 0.5h at high speed. Then reduce the stirring speed, slowly add 70g of organic bentonite, and stir for 20-30 minutes to completely wet the organic bentonite. After the contents of the kettle form a pre-gel, add 30g of propylene carbonate, continue stirring at a high speed for 30-40min, and carry out cyclic shearing until the contents of the kettle form a black and uniform paste-like structure of lubricating grease. During this process, the temperature in the kettle was kept at 80-90°C. Finally, the contents of the kettle are ground by a colloid mill to obtain the finished product.

[0034] The material ratio is described as follows:

[0035] Organic bentonite: 9.9%;

[0036] Refined naphthenic mineral base oil: 85%;

[0037] Multi-walled carbon nanotubes: 0.85%;

[...

Embodiment 3

[0040] Put 15g of treated multi-walled carbon nanotubes and 600g of synthetic hydrocarbon base oil into a stirred tank, raise the temperature to 90-100°C under high-speed stirring, and stir at this temperature for 0.5h at high speed. Then reduce the stirring speed, slowly add 100g of organic bentonite, and stir for 20-30 minutes to completely wet the organic bentonite. After the contents of the kettle form a pre-gel, add 60g of propylene carbonate, continue to stir at a high speed for 30-40min, and carry out circular shearing until the contents of the kettle form a black uniform paste-like grease structure. During this process, the temperature in the kettle was kept at 80-90°C. Finally, the contents of the kettle are ground by a colloid mill to obtain the finished product.

[0041] The material ratio is described as follows:

[0042] Organic bentonite: 12.9%;

[0043] Synthetic hydrocarbon base oil: 77.4%;

[0044] Multi-walled carbon nanotubes: 1.9%;

[0045] Propylene c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com