Process method of seamless sintering bimetallic lining

A processing method, bimetal technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of bushing accuracy maintenance and support capacity discount, and achieve the effect of improving comprehensive performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

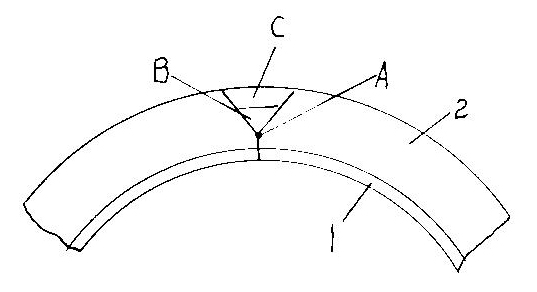

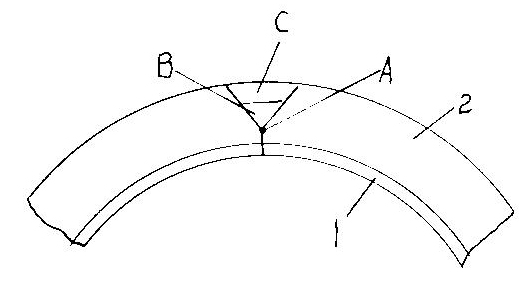

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment the present invention is described in detail as follows:

[0027] The processing method of the seamless sintered bimetal bushing. Its main steps are:

[0028] 1. First, decontaminate and deoxidize the surface of the steel plate, including shot blasting and degreasing;

[0029] Two, the preparation of alloy copper powder; the preparation weight ratio of alloy copper powder is; Copper 80, tin 5, zinc 6 and lead 3; Also add the phosphorus of 2.5, the magnesium of 2.5, the silicon of 2.5 and the molybdenum of 2.5.

[0030] 3. Sintering. Evenly spread alloy copper powder with a thickness of one-fifth of the thickness of the steel plate on the surface of the steel plate, then heat at a high temperature with oxygen barrier, and sinter at a temperature of 800°C for 60 minutes to melt the metal parts other than copper and form the alloy powder into a paste. After cooling, the alloy powder is firmly sintered on the steel plate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com