Micro-pit array-processing method based on laser impact effect

A micro-pit array, laser shock technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of controllable area, improved anti-wear ability, and improved anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

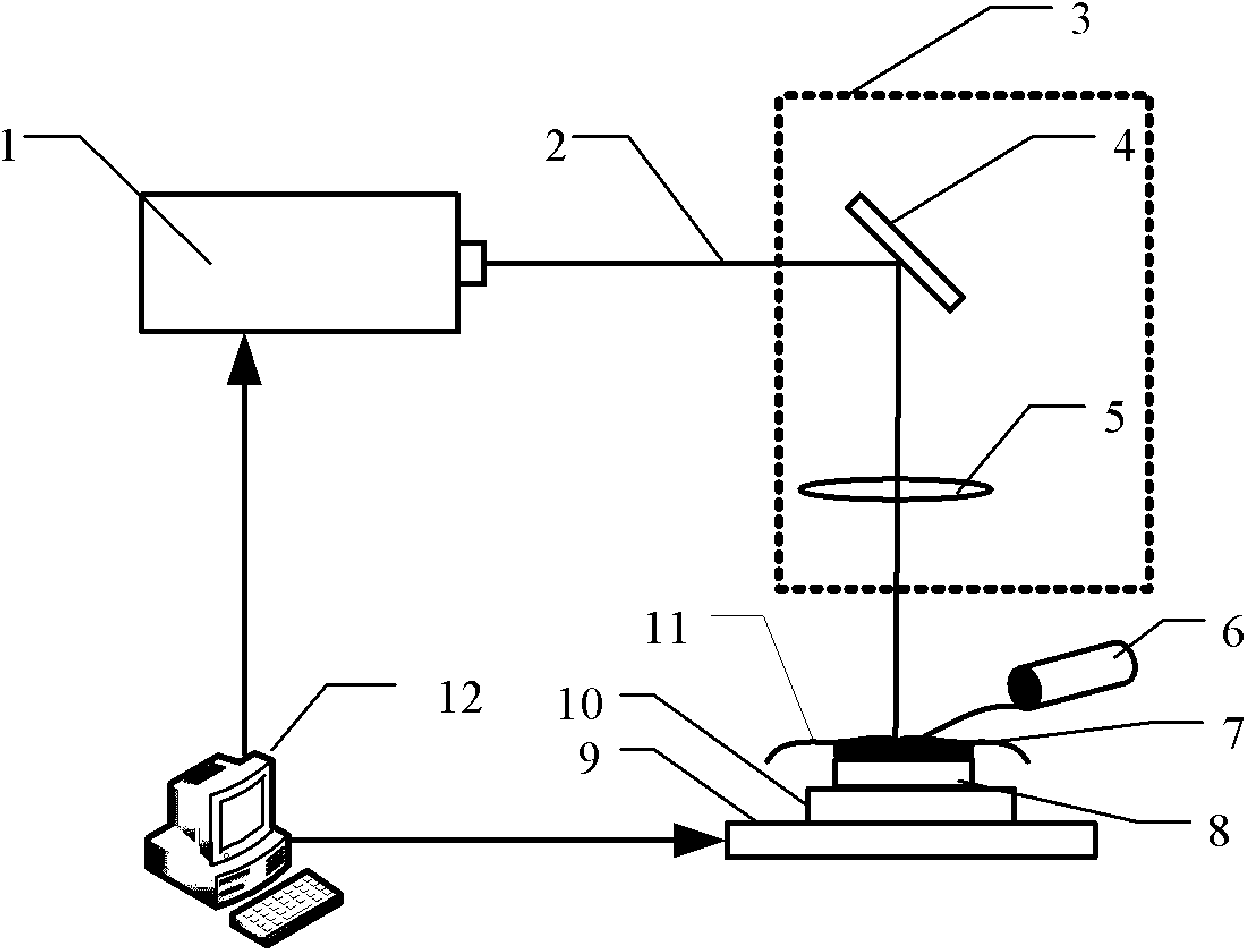

[0017] Such as figure 1 As shown, it is the working environment of this embodiment, wherein: high-energy short-pulse laser 1, laser beam 2, external optical path system 3, water flow nozzle 6, absorption layer 7, workbench 9, workpiece fixture 10, constraining layer 11, control system 12 compositions. The external optical path system 3 includes a mirror 4 and a focusing lens 5 .

[0018] This embodiment implements in the following ways:

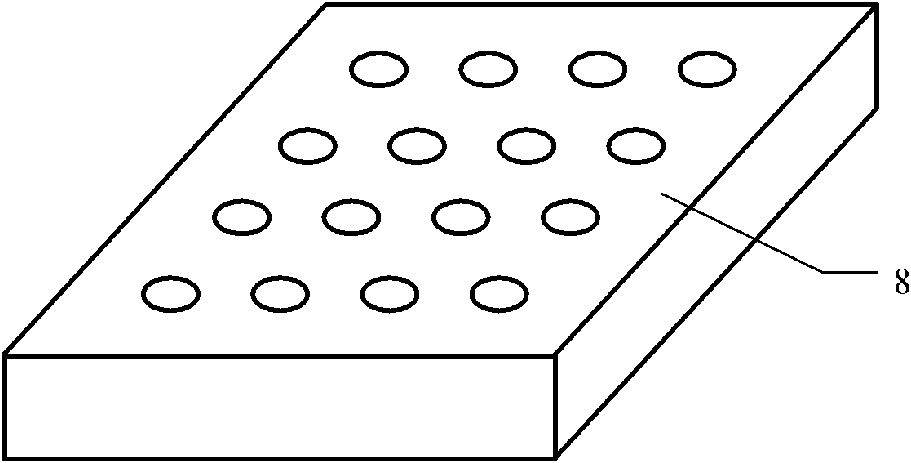

[0019] In the first step, the absorbing layer 7 is attached to the surface of the workpiece 8 to absorb laser energy to generate steam and protect the workpiece fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com