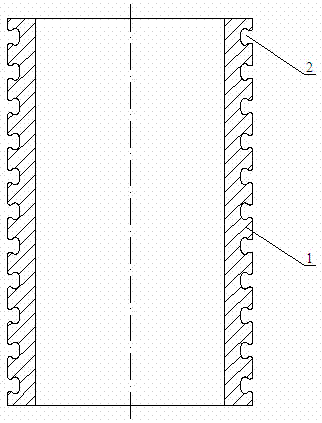

Spiral groove cast-in type air cylinder sleeve and preparation method thereof

A cylinder liner and spiral groove technology, which is applied in the field of energy-saving and lightweight spiral groove cast-in cylinder liner and its preparation, can solve the problems of black smoke from exhaust, low bonding strength, and pollute the environment, so as to improve the processing accuracy and size High stability and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An energy-saving and lightweight spiral groove cast-in cylinder liner, its chemical composition is calculated as follows in weight percentage (%): C: 2.8, Si: 1.2, P: 0.2, S: 0.06, Mn: 0.3, Cu: 0.3, Cr : 0.2, Mo: 0.1, Sn: 0.1, V: 0.05, and the balance is Fe.

[0019] The preparation method of the above-mentioned energy-saving and lightweight spiral groove cast-in cylinder liner includes the following steps:

[0020] (1) The raw materials are proportioned, and the molten iron is obtained by smelting in a medium-frequency induction furnace. The temperature of the molten iron is controlled at 1450 ° C ~ 1500 ° C. Before casting, the molten iron is treated with an inoculant twice. Ferrosilicon inoculant, and the addition amount is 0.4% of the mass of molten iron, and the second inoculation treatment is 75 silicon strontium inoculant, and the addition amount is 0.1% of the mass of molten iron;

[0021] (2) Cylinder liner castings are prepared by metal-type wet paint centrif...

Embodiment 2

[0027] An energy-saving and lightweight spiral groove cast-in cylinder liner, its chemical composition is calculated as follows in weight percentage (%): C: 3, Si: 1.6, P: 0.35, S: 0.1, Mn: 0.5, Cu: 0.5, Cr : 0.35, Mo: 0.2, Sn: 0.15, V: 0.03, and the balance is Fe.

[0028] The preparation method of the above-mentioned energy-saving and lightweight spiral groove cast-in cylinder liner includes the following steps:

[0029] (1) The raw materials are proportioned, and the molten iron is obtained by smelting in a medium-frequency induction furnace. The temperature of the molten iron is controlled at 1450 ° C ~ 1500 ° C. Before casting, the molten iron is treated with an inoculant twice. Ferrosilicon inoculant, and the addition amount is 0.6% of the mass of molten iron, and the second inoculation treatment uses 75 silicon strontium inoculant, and the addition amount is 0.2% of the mass of molten iron;

[0030] (2) Cylinder liner castings are prepared by metal-type wet paint centr...

Embodiment 3

[0034] An energy-saving and lightweight spiral groove cast-in cylinder liner, its chemical composition is calculated as follows in weight percentage (%): C: 3.5, Si: 2.1, P: 0.5, S: 0.12, Mn: 0.7, Cu: 0.7, Cr : 0.5, Mo: 0.4, Sn: 0.2, V: 0.15, and the balance is Fe.

[0035] The preparation method of the above-mentioned energy-saving and lightweight spiral groove cast-in cylinder liner includes the following steps:

[0036] (1) The raw materials are proportioned, and the molten iron is obtained by smelting in a medium-frequency induction furnace. The temperature of the molten iron is controlled at 1450 ° C ~ 1500 ° C. Before casting, the molten iron is treated with an inoculant twice. Ferrosilicon inoculant, and the addition amount is 0.8% of the mass of molten iron, and the second inoculation treatment uses 75 silicon strontium inoculant, and the addition amount is 0.3% of the mass of molten iron;

[0037] (2) Cylinder liner castings are prepared by metal-type wet paint centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com