Anti-wear anti-friction gear lubricating oil and preparation method thereof

A technology of gear lubricating oil and rapeseed oil, which is applied in the field of gear lubricating oil, can solve the problems of anti-wear and anti-friction performance to be improved, and poor anti-extreme pressure effect, so as to improve anti-wear and anti-friction effect and promote compatibility , Good anti-extreme pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

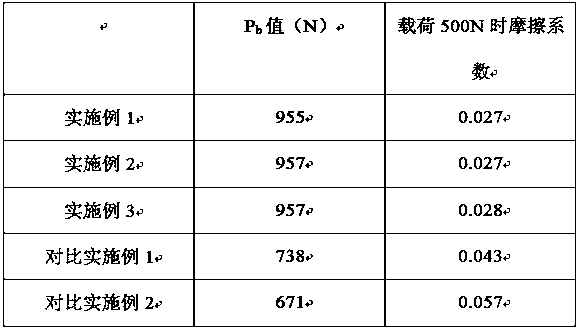

Examples

Embodiment 1

[0020] An anti-wear and anti-friction gear lubricating oil is characterized in that it is made of the following raw materials in parts by weight:

[0021] Nano zirconia 5, sodium petroleum sulfonate 1, phosphate ester 0.5, manganese sulfate solution 30, potassium permanganate solution 20, rapeseed oil 40, base oil 20, meal waste oil 30, phthalic anhydride isoheptanol 3, polyisobutylene 2, sodium alginate 2.

[0022] Further, its preparation method comprises the following steps:

[0023] (1) Add nano-zirconia to deionized water 10 times its volume, then add sodium petroleum sulfonate, stir at 800rpm for 30min, then add phosphoric acid ester, raise the temperature to 60°C, continue stirring for 20min, centrifuge, and remove the supernatant liquid, and put the resultant into a drying oven at 100°C for drying;

[0024] (2) Add the resultant of step (1) to the manganese sulfate solution, ultrasonicate at 40°C for 45 minutes, then cool down to 2°C, add potassium permanganate solut...

Embodiment 2

[0032] An anti-wear and anti-friction gear lubricating oil is characterized in that it is made of the following raw materials in parts by weight:

[0033] Nano zirconia 7, sodium petroleum sulfonate 2, phosphate ester 0.8, manganese sulfate solution 40, potassium permanganate solution 25, rapeseed oil 50, base oil 25, meal waste oil 32, phthalic anhydride isoheptanol 4, polyisobutylene 3, sodium alginate 4.

[0034] Further, its preparation method comprises the following steps:

[0035] (1) Add nano-zirconia to deionized water 15 times its volume, then add sodium petroleum sulfonate, stir at 850rpm for 35min, then add phosphoric acid ester, raise the temperature to 62°C, continue stirring for 25min, centrifuge, and remove the supernatant liquid, and put the resultant into a drying oven at 105°C for drying;

[0036] (2) Add the resultant of step (1) to the manganese sulfate solution, ultrasonicate at 45°C for 50 minutes, then cool down to 3°C, add potassium permanganate solut...

Embodiment 3

[0044] An anti-wear and anti-friction gear lubricating oil is characterized in that it is made of the following raw materials in parts by weight:

[0045] Nano zirconia 10, sodium petroleum sulfonate 2, phosphate ester 0.8, manganese sulfate solution 50, potassium permanganate solution 30, rapeseed oil 55, base oil 28, meal waste oil 35, phthalic anhydride isoheptanol 5, polyisobutylene 3, sodium alginate 5.

[0046] Further, its preparation method comprises the following steps:

[0047] (1) Add nano-zirconia to deionized water 20 times its volume, then add sodium petroleum sulfonate, stir at 900rpm for 40min, then add phosphoric acid ester, raise the temperature to 65°C, continue stirring for 30min, centrifuge, and remove the supernatant liquid, and put the resultant into a drying oven at 110°C for drying;

[0048] (2) Add the product obtained in step (1) to the manganese sulfate solution, ultrasonicate at 50°C for 55 minutes, then cool down to 4°C, add potassium permangana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com