Compound lithium base grease composite and preparation method thereof

A technology of base lubricating grease and composition, which is applied in the field of composite lithium-based lubricating grease composition and its preparation, to achieve good colloidal stability, good high temperature performance and extreme pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

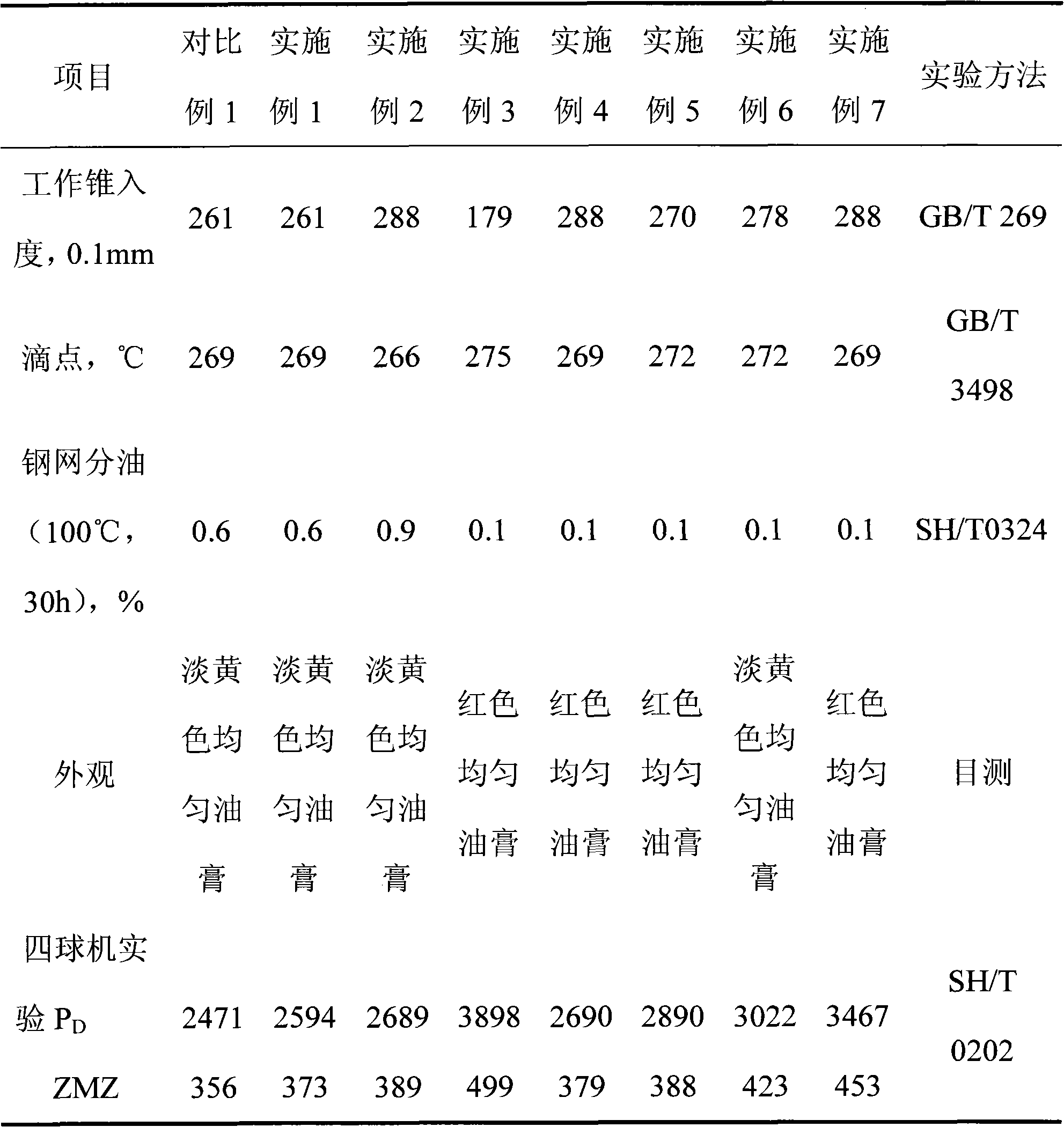

Examples

Embodiment 1

[0021] Add 57 grams of 12-hydroxystearic acid and 587 grams of base oil into the reactor, wherein the base oil is mineral oil, heat and stir, add lithium hydroxide hot solution for saponification. Raise the system temperature to 150°C, then raise the temperature to 210°C, then lower the system temperature to 100°C, add 21 grams of sebacic acid, and add lithium hydroxide hot solution. The temperature of the system was raised to 150°C. Turn off the heat and add 3 g d 50 = Bismuth oxide powder particles of 20 microns, keep stirring, and wait for the system to cool naturally to room temperature to obtain the product

Embodiment 2

[0023] Add 14 grams of 12-hydroxystearic acid and 178 grams of base oil into the reactor, wherein the base oil is mineral oil, heat and stir, add lithium hydroxide hot solution for saponification. Raise the system temperature to 150°C, then raise the temperature to 220°C, then lower the system temperature to 110°C, add 6 grams of sebacic acid, and add lithium hydroxide hot solution. The temperature of the system was raised to 150°C. Turn off the heat and add 1 g d 50 =10 micron bismuth oxide powder particles and 1 gram of diisooctyldiphenylamine, keep stirring, and wait for the system to cool naturally to room temperature to obtain the product.

Embodiment 3

[0025] Add 36 grams of 12-hydroxystearic acid and 140 grams of base oil into the reactor, wherein the base oil is a mixture of naphthenic base oil and paraffin base oil, heat and stir, add lithium hydroxide hot solution for saponification. Raise the system temperature to 150°C, then raise the temperature to 215°C, then lower the system temperature to 105°C, add 14 grams of sebacic acid, and add lithium hydroxide hot solution. The temperature of the system was raised to 150°C. Turn off the heat and add 8 g d 50 = 10 micron bismuth oxide powder particles and 1 gram of diisooctyl diphenylamine and 1 gram of Sudan III, keep stirring, and wait for the system to cool naturally to room temperature to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com