Composite calcium sulfonate based lubricating grease for open gear as well as preparation method and application thereof

A composite calcium sulfonate-based, composite calcium sulfonate technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor temperature resistance, poor extreme pressure performance, and small sintering load, and achieve excellent extreme pressure resistance The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides the preparation method of the composite calcium sulfonate-based open gear grease described in the above technical solution, comprising the following steps:

[0041] Mix the composite calcium sulfonate thickener with part of the base oil for phase inversion reaction to obtain the phase inversion reaction product;

[0042] Mixing the phase inversion reaction product, ethylene propylene rubber and the remaining base oil to obtain a mixed material;

[0043] After the mixed material is filtered, firstly cooled, sheared and refluxed and secondly cooled, mixed with diphenylamine, sulfurized olefin, calcium petroleum sulfonate and graphite to obtain the composite calcium sulfonate-based open gear grease.

[0044] The invention mixes the composite calcium sulfonate thickener and part of the base oil for phase inversion reaction to obtain a phase inversion reaction product. In the present invention, the complex calcium sulfonate thickener is ...

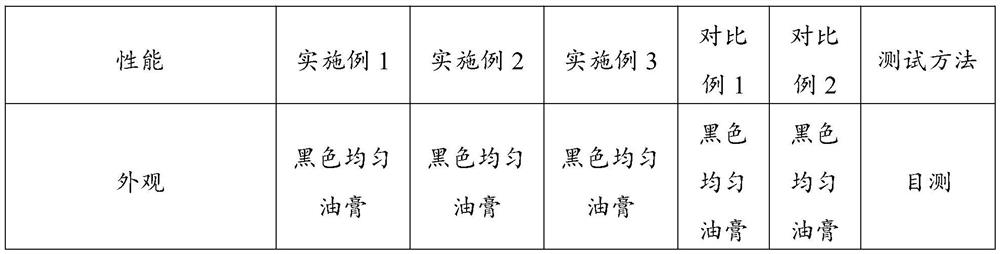

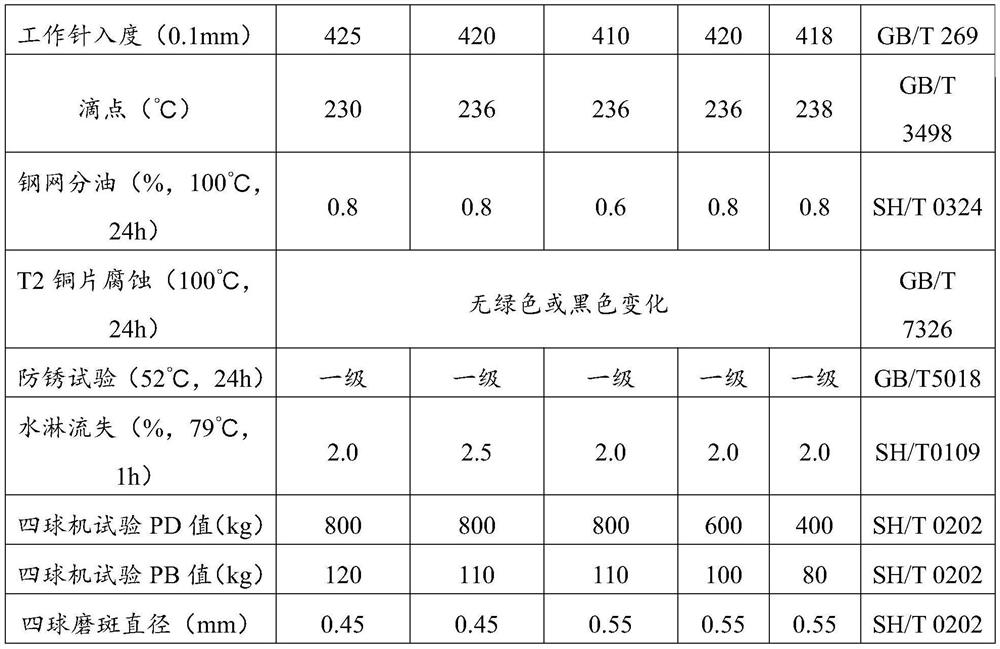

Embodiment 1~3

[0060] Press the consumption of raw material in table 1, prepare compound calcium sulfonate base type lubricating grease for open gear, concrete preparation method is as follows:

[0061] (1) Mix 150BS bright stock and polyethylene propylene synthetic oil to obtain base oil;

[0062] (2) isopropanol and part of water are mixed to obtain isopropanol aqueous solution, and the mass ratio of isopropanol and part of water is 3:7;

[0063] Glacial acetic acid is mixed with remaining water to obtain an aqueous solution of glacial acetic acid, and the mass ratio of glacial acetic acid and remaining water is 1:3;

[0064] Add part of the base oil and high alkalinity petroleum calcium sulfonate T106D into the saponification kettle, stir and heat up to 70°C, and the speed is 30rpm, add isopropanol aqueous solution and calcium carbonate, heat up to 75°C while stirring, add glacial acetic acid Aqueous solution, carry out the first phase inversion reaction, after 5 minutes, when the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com