Molybdenum disulfide lubricating spray and preparation method thereof

A technology of molybdenum disulfide and spray, which is applied in the direction of lubricating composition, coating, petroleum industry, etc., can solve the problems of high long-term cost, small temperature resistance range, limited lubricating performance, etc., and achieves wide applicability, simple use, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

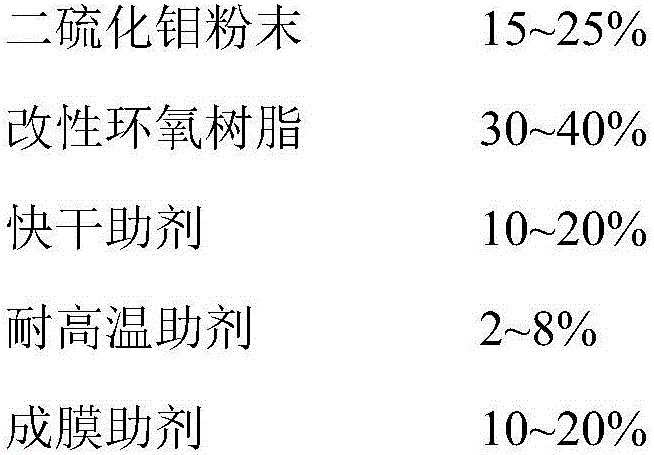

[0040] The preparation of embodiment 1 quick-drying type molybdenum disulfide lubricating spray comprises the component of following percentage by weight:

[0041]

[0042] Specific preparation method:

[0043] (1) Weigh molybdenum disulfide powder, modified epoxy resin and high-temperature-resistant auxiliary agent in the formula amount, stir at 100-120r / min for 5min under the temperature condition of 30-35°C, and mix evenly to obtain mixture A;

[0044] (2) Stir the rest of the raw materials at 200-250r / min for 10-50min, and mix well to obtain mixture B;

[0045] (3) Put the mixture A and the mixture B into the dispersing tank and stir. After dispersing and stirring at 200-250r / min at room temperature for 20-30 minutes, add the empty spray tank for filling and sealing;

[0046] (4) Under normal temperature and pressure, add propellant into the spray tank, install valves, bottle caps, inspect and pack.

Embodiment 2

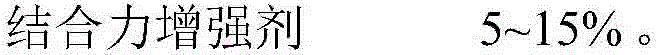

[0047] The preparation of embodiment 2 heat-resistant molybdenum disulfide lubricating sprays, comprise the component of following weight percent:

[0048]

[0049]

[0050] Specific preparation method:

[0051] (1) Weigh molybdenum disulfide powder, modified epoxy resin and high-temperature-resistant auxiliary agent in the formula amount, stir at 100-120r / min for 5min under the temperature condition of 30-35°C, and mix evenly to obtain mixture A;

[0052] (2) Stir the rest of the raw materials at 200-250r / min for 10-50min, and mix well to obtain mixture B;

[0053] (3) Put the mixture A and the mixture B into the dispersing tank and stir. After dispersing and stirring at 200-250r / min at room temperature for 20-30 minutes, add the empty spray tank for filling and sealing;

[0054] (4) Under normal temperature and pressure, add propellant into the spray tank, install valves, bottle caps, inspect and pack.

Embodiment 3

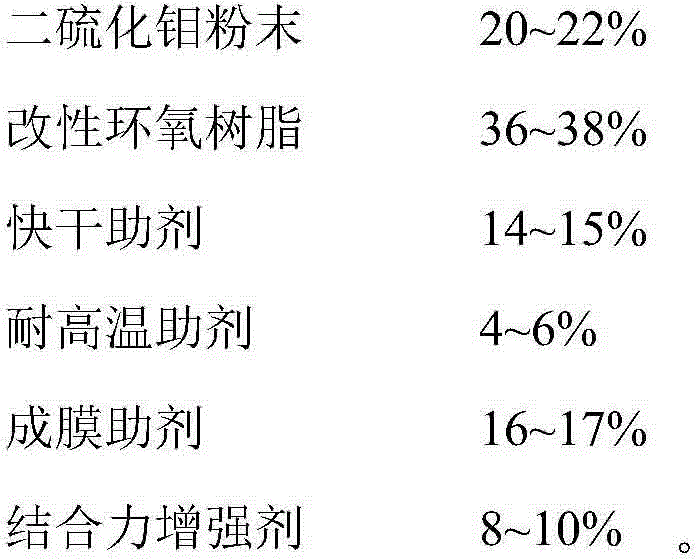

[0055] The preparation of embodiment 3 popular molybdenum disulfide lubricating sprays, comprises the component of following weight percent:

[0056]

[0057] Specific preparation method:

[0058] (1) Weigh molybdenum disulfide powder, modified epoxy resin and high-temperature-resistant auxiliary agent in the formula amount, stir at 100-120r / min for 5min under the temperature condition of 30-35°C, and mix evenly to obtain mixture A;

[0059] (2) Stir the rest of the raw materials at 200-250r / min for 10-50min, and mix well to obtain mixture B;

[0060] (3) Put the mixture A and the mixture B into the dispersing tank and stir. After dispersing and stirring at 200-250r / min at room temperature for 20-30 minutes, add the empty spray tank for filling and sealing;

[0061] (4) Under normal temperature and pressure, add propellant into the spray tank, install valves, bottle caps, inspect and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com