Preparation of extreme pressure anti-wear agent and vehicle gear oil containing extreme pressure anti-wear agent

A technology of extreme pressure antiwear agent and gear oil, which is applied in additives, petroleum industry, organic chemistry, etc. It can solve the problems of poor multifunctionality, anti-oxidation, anti-cleaning performance and weak repair function, and achieve good wear resistance, Effect of lower friction coefficient, good load carrying capacity and extreme pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a preparation method of an extreme pressure antiwear agent, and a vehicle gear oil containing the extreme pressure antiwear agent.

[0030] A preparation method of an extreme pressure antiwear agent, specifically comprising the following steps:

[0031] a, add the borax of 115mg in the 80mg lanthanum nitrate solution and react, and the reaction time is 2h;

[0032] B, then add 89mg of n-butanol to the lanthanum nitrate solution to carry out esterification reaction, the reaction time is 3h;

[0033] c. After the esterification reaction is finished, add an appropriate amount of 100mg dodecyl alcohol-modified graphene oxide to carry out a transesterification reaction to obtain a preliminary reaction solution;

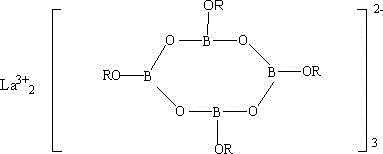

[0034] d. Distilling the preliminary reaction solution to remove impurities to obtain graphene modified by lanthanum dodecyloxyborate, which is the extreme pressure antiwear agent;

[0035] A vehicle gear oil prepared by using an extreme p...

Embodiment 2

[0037] This embodiment provides a preparation method of an extreme pressure antiwear agent, and a vehicle gear oil containing the extreme pressure antiwear agent.

[0038] A preparation method of an extreme pressure antiwear agent, specifically comprising the following steps:

[0039] a, add the borax of 116mg in 90mg lanthanum nitrate solution and react, and the reaction time is 3h;

[0040] B, then add 89mg of n-butanol to the lanthanum nitrate solution to carry out esterification reaction, the reaction time is 5h;

[0041] c. After the esterification reaction is finished, add an appropriate amount of 104 mg dodecyl alcohol-modified graphene oxide to carry out a transesterification reaction to obtain a preliminary reaction solution;

[0042] d. Distilling the preliminary reaction solution to remove impurities to obtain graphene modified by lanthanum dodecyloxyborate, which is the extreme pressure antiwear agent;

[0043] A vehicle gear oil prepared by using an extreme pres...

Embodiment 3

[0045] This embodiment provides a preparation method of an extreme pressure antiwear agent, and a vehicle gear oil containing the extreme pressure antiwear agent.

[0046] A preparation method of an extreme pressure antiwear agent, specifically comprising the following steps:

[0047] a, add the borax of 114mg in the 88mg lanthanum nitrate solution and react, and the reaction time is 4h;

[0048] B, then add 86mg of n-butanol to the lanthanum nitrate solution to carry out esterification reaction, the reaction time is 6h;

[0049]c. After the esterification reaction is finished, add an appropriate amount of 98mg dodecyl alcohol-modified graphene oxide to carry out a transesterification reaction to obtain a preliminary reaction solution;

[0050] d. Distilling the preliminary reaction solution to remove impurities to obtain graphene modified by lanthanum dodecyloxyborate, which is the extreme pressure antiwear agent;

[0051] A vehicle gear oil prepared by using an extreme pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com