Special cold ring rolling oil composition for bearing processing

A technology of bearing processing and oil composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of shortening the service life of cold rolling machine, insufficient extreme pressure of water-based lubricant, rough workpiece surface, etc., and achieve excellent Anti-friction performance and anti-extreme pressure performance, inhibit thermal fatigue wear, improve the effect of workpiece surface roughness and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

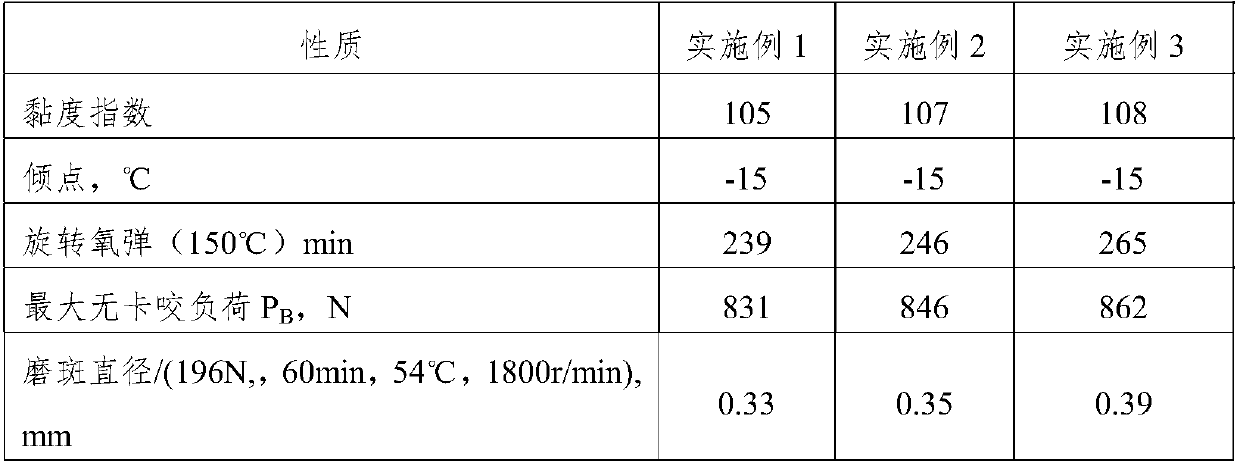

Examples

Embodiment 1

[0043] This embodiment discloses a cold rolling oil expansion composition, the formula is as follows: 3 kg of anti-oxidant anti-corrosion agent zinc dialkyldithiophosphate (purchased from Lubrizol Lanlian Additive Co., Ltd.), and the antirust agent is dodecene Succinic acid (purchased from Wuxi Nanfang Petroleum Additive Co., Ltd.) 0.05kg, extreme pressure antiwear agent vulcanized olefin cottonseed oil (purchased from Jinzhou Shengda Chemical Co., Ltd.) 15kg, 1# composite antifoaming agent 0.005kg, solvent refined Base oil (purchased from Maoming Petrochemical, with a kinematic viscosity of 32.4mm at 40°C 2 / s) 81.95kg.

[0044] The present embodiment provides the preparation method of the above-mentioned composition at the same time, specifically as follows: take 3 kg of zinc dialkyl dithiophosphate, 0.05 kg of dodecenyl succinic acid, 15 kg of vulcanized olefin cottonseed oil, and then sequentially add to 81.95 kg of solvent Refining the base oil, mixing and stirring at 60...

Embodiment 2

[0046] This embodiment discloses a cold rolling oil expansion composition, the formula is as follows: 3 kg of anti-oxidant anti-corrosion agent zinc dialkyldithiophosphate (purchased from Lubrizol Lanlian Additive Co., Ltd.), and the antirust agent is dodecene Succinic acid (purchased from Wuxi Nanfang Petroleum Additive Co., Ltd.) 0.05kg, extreme pressure antiwear agent vulcanized olefin cottonseed oil (purchased from Jinzhou Shengda Chemical Co., Ltd.) 23kg, 1# composite antifoaming agent 0.005kg, solvent refined Base oil (purchased from Maoming Petrochemical, with a kinematic viscosity of 31.9mm at 40°C 2 / s) 73.95kg.

[0047] The present embodiment provides the preparation method of the above-mentioned composition at the same time, specifically as follows: take 3 kg of zinc dialkyl dithiophosphate, 0.05 kg of dodecenyl succinic acid, 23 kg of vulcanized olefin cottonseed oil, and then sequentially add to 73.95 kg of solvent Refining the base oil, mixing and stirring at 60...

Embodiment 3

[0049]This embodiment discloses a cold rolling oil expansion composition, the formula is as follows: 4 kg of anti-oxidant antiseptic zinc dialkyldithiophosphate (purchased from Lubrizol Lanlian Additive Co., Ltd.), and the antirust agent is dodecene Succinic acid (purchased from Wuxi Nanfang Petroleum Additive Co., Ltd.) 0.05kg, extreme pressure antiwear agent vulcanized olefin cottonseed oil (purchased from Jinzhou Shengda Chemical Co., Ltd.) 28kg, 1# composite antifoaming agent 0.005kg, solvent refined Base oil (purchased from Maoming Petrochemical, with a kinematic viscosity of 32.1mm at 40°C 2 / s) 67.95kg.

[0050] The present embodiment provides the preparation method of the above-mentioned composition at the same time, specifically as follows: take 4kg of zinc dialkyldithiophosphate, 0.05kg of dodecenylsuccinic acid, 28kg of vulcanized olefin cottonseed oil, and then add them to 67.95kg of Solvent refined base oil, mixed and stirred at 60°C for 1 hour, then added 0.005 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com