Turbine worm lubricating grease composition and preparation method thereof

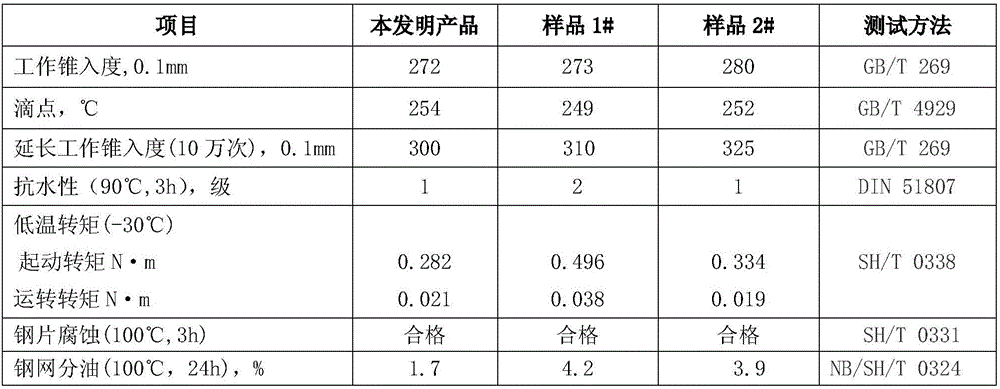

A grease composition and a technology for a worm gear, applied in the field of grease, can solve problems such as poor lubrication and poor performance, and achieve outstanding water resistance, low oil separation rate, and small evaporation loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: each component comprises by the total weight of composition:

[0030] PAO 100: PAO 40 = 4:1 85%;

[0031] 12-Hydroxy:Sebacic acid=5:1 15%;

[0032] According to the total amount of the above two components, add the following additive mass percentages:

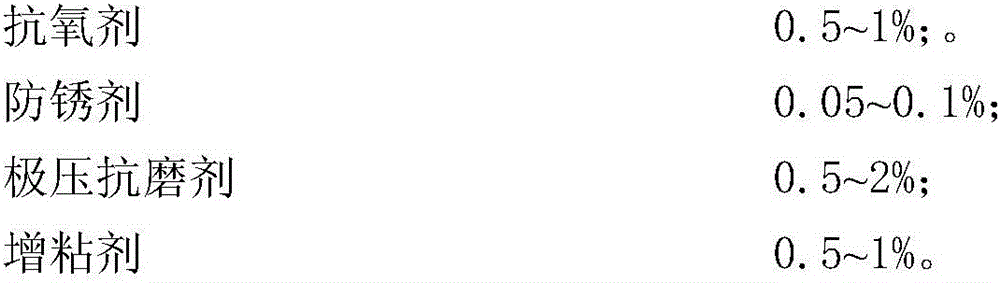

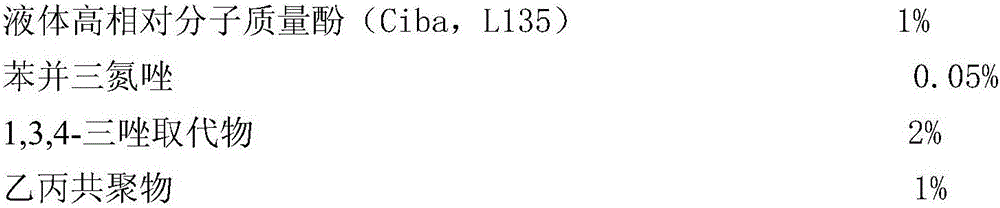

[0033]

[0034] Mix 125g of 12-hydroxystearic acid, 25g of sebacic acid and 510 base oil (the freezing point is -30°C, the viscosity at 100°C is 20mm 2 / s) Put it into the reaction kettle, heat until it is completely melted, then add 170g of base oil to lower the temperature in the kettle to 85-92°C, add 7.66g of lithium hydroxide monohydrate and 3.83g of calcium hydroxide for saponification After the saponification is completed, the temperature is raised to 100-110°C, and the remaining 15.32g of lithium hydroxide (1:5 water) solution is added dropwise. Cool down, add 170g of base oil when the temperature reaches about 180°C, add 10g of antioxidant when the temperature drops to 160-170°C, add 20g of e...

Embodiment 2

[0038] Embodiment 2: each component comprises by the total weight of composition:

[0039] PAO 100: PAO 40 = 4:1 86%;

[0040] 12-hydroxyl:sebacic acid=5:1 14%;

[0041] According to the total amount of the above two components, add the following additive mass percentages:

[0042]

[0043] Mix 117g 12-hydroxystearic acid, 23g sebacic acid and 520 base oil (the freezing point is -30°C, the viscosity at 100°C is 20mm 2 / s) into the reaction kettle, heated until completely melted, then added 170g of base oil to lower the temperature in the kettle to 85-92°C, added 7.15g of lithium hydroxide monohydrate and 3.57g of calcium hydroxide for saponification After the saponification is completed, the temperature is raised to 100-110°C, and the remaining 14.30g of lithium hydroxide (1:5 water) solution is added dropwise. Cool down, add 170g of base oil when the temperature reaches about 180°C, add 10g of antioxidant when the temperature drops to 160-170°C, add 20g of extreme press...

Embodiment 3

[0047]Embodiment 3: each component comprises by the total weight of composition:

[0048] PAO 100: PAO 40 = 4:1 87%;

[0049] 12-hydroxyl:sebacic acid=5:1 13%;

[0050] According to the total amount of the above two components, add the following additive mass percentages:

[0051]

[0052] Mix 108g of 12-hydroxystearic acid, 22g of sebacic acid and 520 base oil (the freezing point is -30°C, the viscosity at 100°C is 20mm 2 / s) into the reaction kettle, heated until completely melted, then added 180g of base oil to lower the temperature in the kettle to 85-92°C, and added 6.64g of lithium hydroxide monohydrate and 3.32g of calcium hydroxide for saponification After the saponification is completed, the temperature is raised to 100-110°C, and the remaining 13.27g of lithium hydroxide (1:5 water) solution is added dropwise. Cool down, add 170g of base oil when the temperature is around 180°C, add 10g of antioxidant when the temperature drops to 160-170°C, add 10g of extreme ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com