Coupled dimercaptotriazine derivative, and preparation method and use thereof

A bismercaptotriazine and derivative technology, applied in the field of lubricating additives, can solve the problems of extreme pressure and anti-wear properties that need to be further improved, containing phosphorus elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

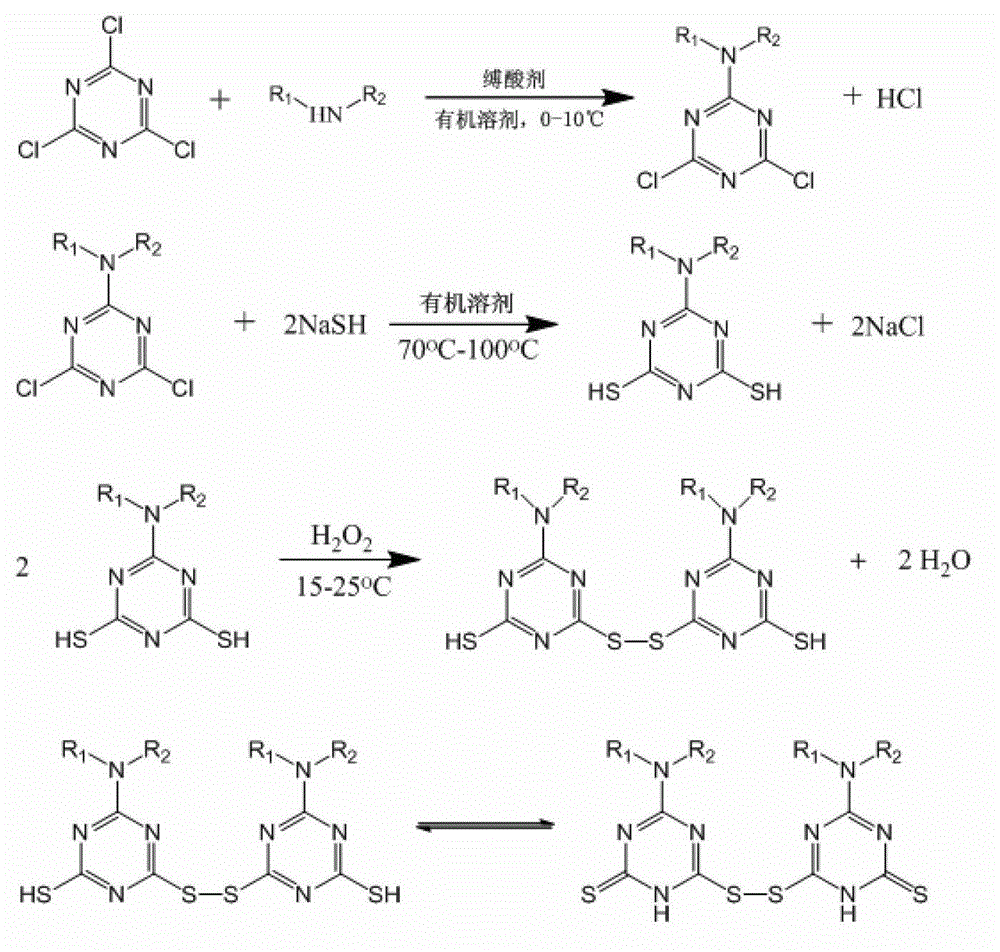

[0029] The synthesis of the coupled bismercaptotriazine derivative extreme pressure antiwear agent of the present embodiment is as follows: figure 1 As shown, the details are as follows:

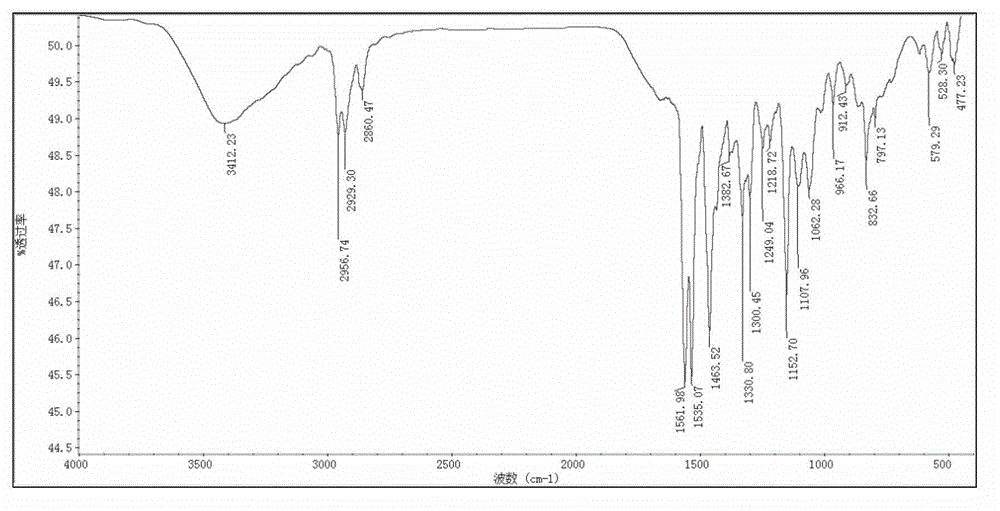

[0030] 1) Add 18.45g of 2,4,6-trichloro-1,3,5-triazine into 150ml of organic solvent (acetone), and heat at 0°C (0-10°C is acceptable, 0°C is selected in this embodiment) Slowly add 12.9g of di-n-butylamine (feeding ratio 1:1) and 6.9g of acid-binding agent (potassium carbonate) under stirring, continue to react for 1.5 hours after the addition is completed, pour into ice water after the reaction, separate liquids, and use organic Diluted with solvent (ether), dried, filtered, and the filtrate was rotary evaporated to obtain 24.4 g of intermediate 1 (2-di-n-butylamino-4,6-dichloro-1,3,5-triazine), with a yield of 88.1%. The intermediate is a yellow oily liquid.

[0031] 2) Take 13g of sodium hydrosulfide and dissolve it in 300ml of organic solvent (ethanol), then slowly add 21g of intermedia...

Embodiment 2

[0037] The synthesis of the coupled bismercaptotriazine derivative extreme pressure antiwear agent of the present embodiment is as follows: figure 1 As shown, the details are as follows:

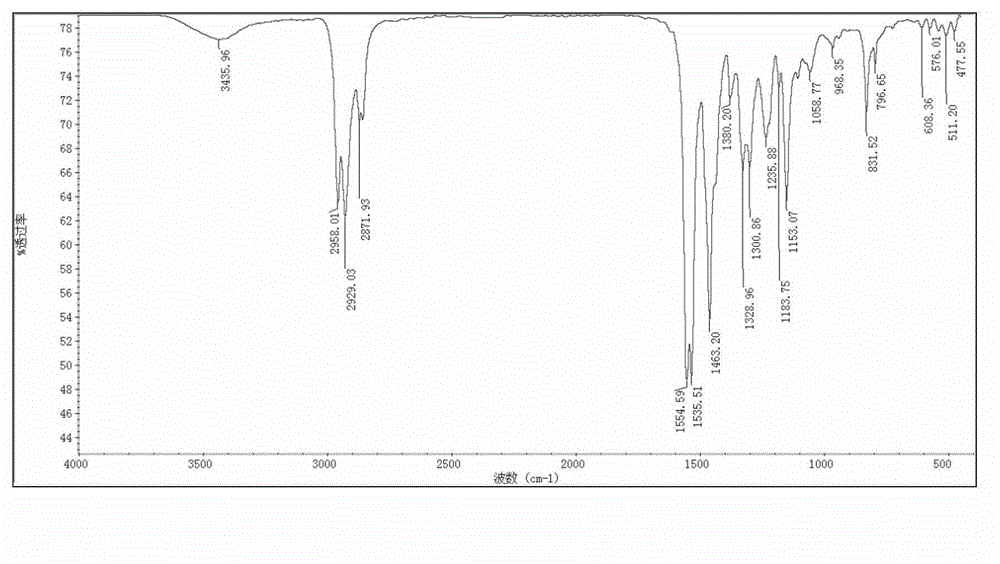

[0038] 1) Add 18.45g of 2,4,6-trichloro-1,3,5-triazine into 150ml of organic solvent (chloroform), slowly add 24.15g of diisooctylamine under stirring at 0°C (feeding ratio 1: 1) and 2g of acid-binding agent (sodium hydroxide), continue to react for 2.5 hours after the addition is complete, pour into ice water after the reaction, separate the liquids, dilute the organic phase with an organic solvent (ether), dry, filter, and the filtrate is rotary evaporated to obtain the intermediate Compound 1 (2-Diisooctylamino-4,6-dichloro-1,3,5-triazine) 34.0g, yield 87.3%, this intermediate is brown oily liquid.

[0039] 2) Dissolve 15g of sodium hydrosulfide in 350ml of organic solvent (ethanol), then slowly add 33.5g of intermediate 1 (feeding ratio is about 1:2.2), the reaction temperature is 70°C ...

Embodiment 3

[0044] Embodiment 3, extreme pressure and anti-wear performance test

[0045] The extreme pressure and antiwear properties of the two coupled bismercaptotriazine derivatives obtained in Example 1 and Example 2 are tested as follows:

[0046] 1. Extreme pressure performance test

[0047] According to the GB3142-82 standard, the bis-mercaptotriazine derivatives of lithium-based grease and two couplings prepared by example 1 and 2 were added in lithium-based grease and rapeseed oil and the coupled bis-mercapto group prepared by example 2 The maximum non-seizing load of triazine derivatives added in rapeseed oil (P B value) was measured. The four-ball machine used in the experiment is the MS-10JB four-ball machine produced by Xiamen Testing Machine Factory. The steel ball used is the second-grade GCr15 standard steel ball (AISI-52100), with a diameter of 12.7mm and a hardness of 59-61HRC. Carried out at room temperature with a rotation speed of 1760 rpm. The results are list...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com