High-corrosion-resistance metal anti-corrosive paint and preparation method thereof

A metal anti-corrosion and corrosive technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as obstacles, corrosion production development and scientific and technological progress

Inactive Publication Date: 2015-02-25

ZHANGJIAGANG FREE TRADE ZONE GUANXIANG TRADE

View PDF2 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, corrosion may also become an obstacle to production development and technological progress.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

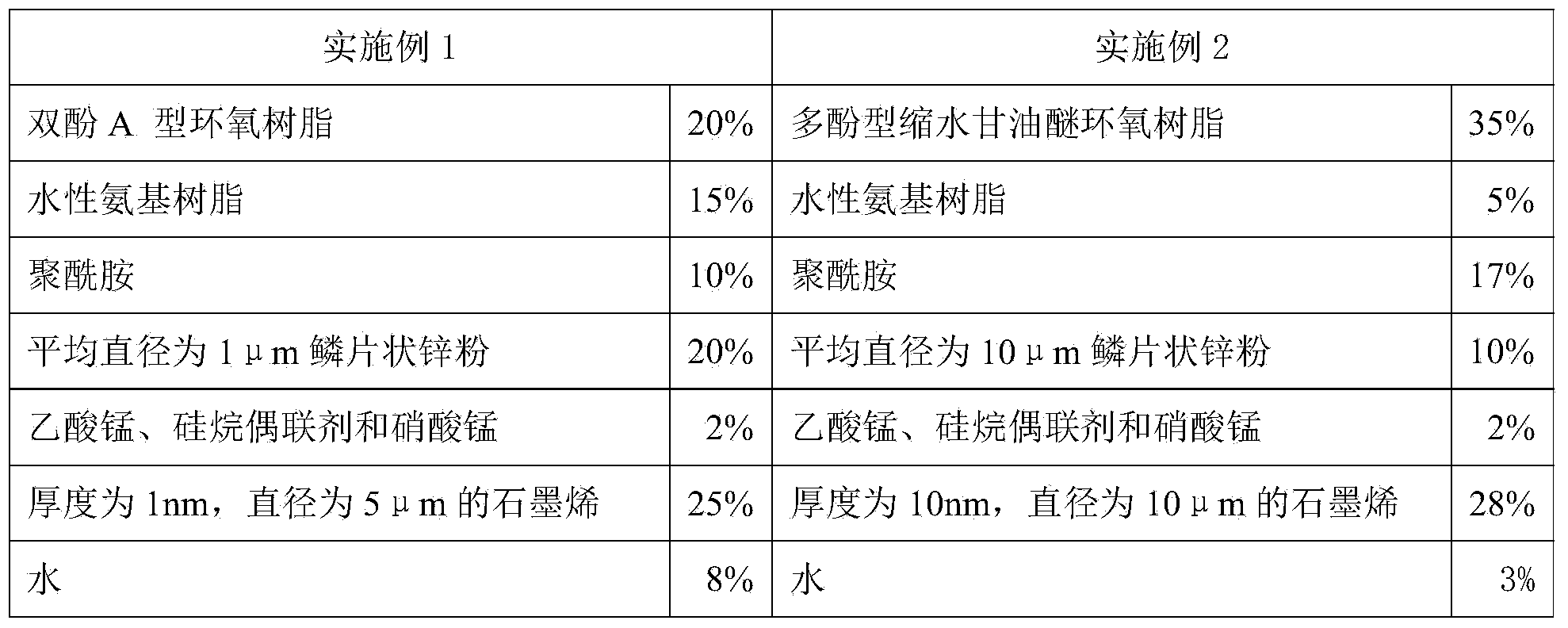

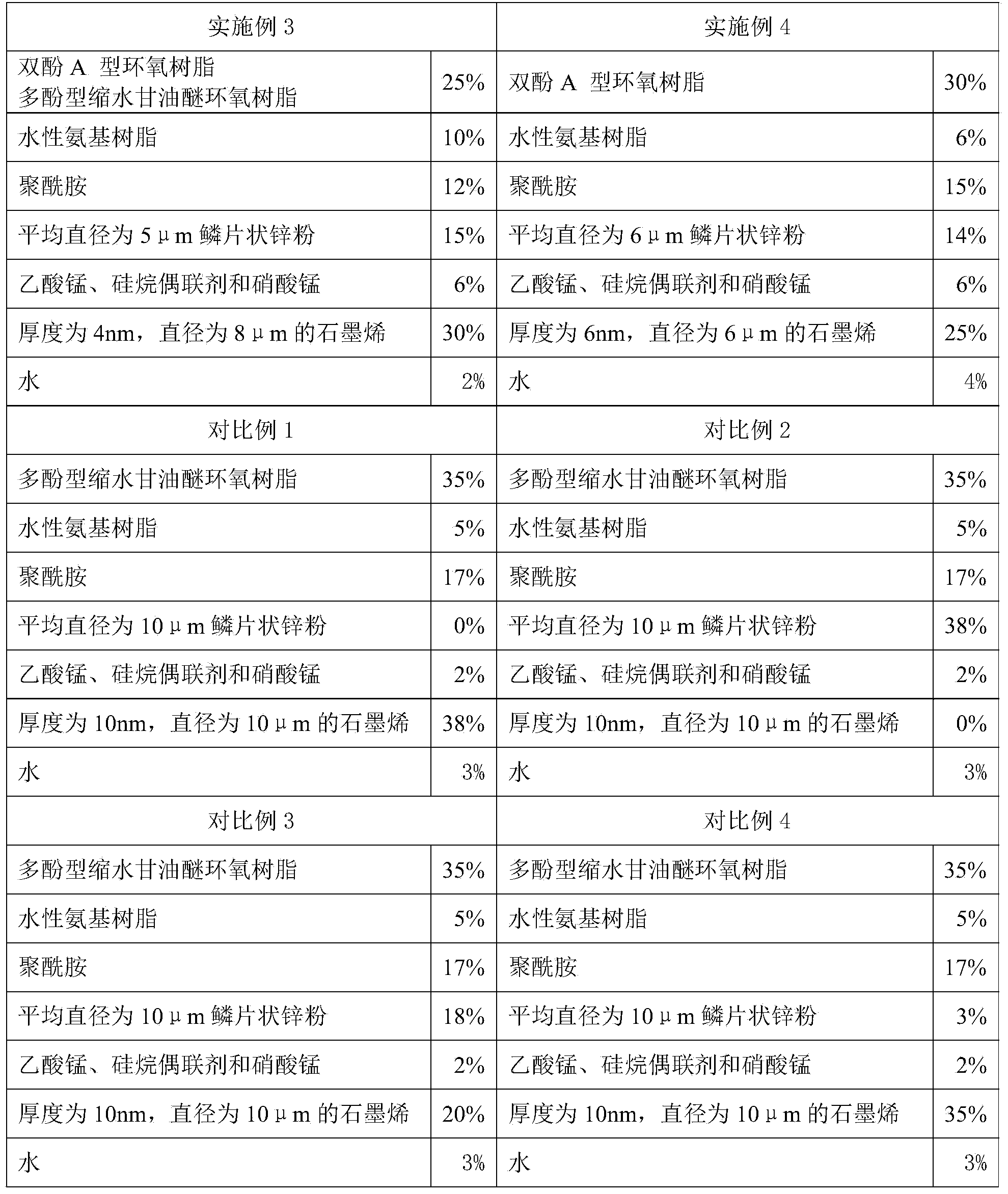

[0022] A preparation method of high corrosion resistance metal anticorrosive coating includes the following steps:

[0023] Weigh the components in proportion; mix the epoxy resin, water-based amino resin and water in a mixer with a stirring speed of 1200rpm for 3-5 minutes, then add zinc powder, film-forming agent and graphene and stir well 5 -10 minutes, finally add polyamide and stir for 3-5 minutes.

[0024]

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

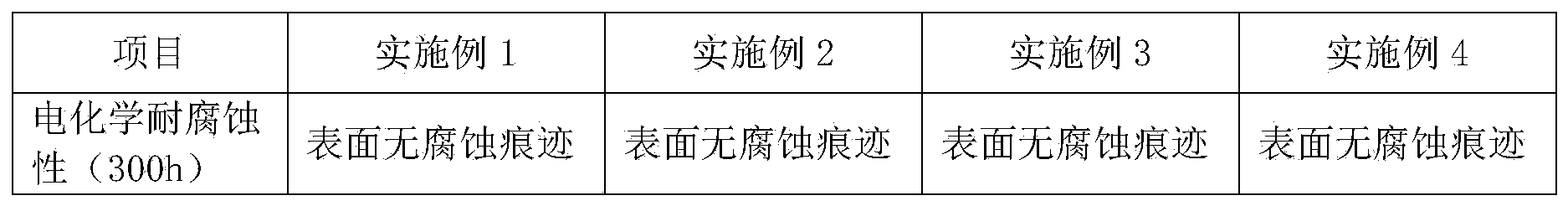

The invention relates to the technical field of corrosion prevention of metals, and particularly relates to a high-corrosion-resistance metal anti-corrosive paint. The paint consists of the following components in percentage by mass: 20-35 percent of epoxy resin, 5-15 percent of water-based amino resin, 10-17 percent of polyamide, 10-20 percent of zinc powder, 2-6 percent of a film forming agent, 25-30 percent of graphene and the balance of water. The high-corrosion-resistance metal anti-corrosive paint disclosed by the invention has a good rustproof effect on metals by strictly controlling the amount of used zinc and grapheme, and can be used for slowing down metal corrosion, lowering the cost and also forming a uniform passivation layer and a uniform corrosion inhibition layer on the surface of a metal so that an overall coating is subjected to synchronous corrosion inhibition, and the anti-corrosive paint for a boat is endowed with excellent waterproofness, alkali resistance, artificial weathering aging resistance and corrosion resistance. The adopted paint system is a water-based paint system which has an excellent anti-corrosive effect in seawater, so the application range of the paint is effectively widened.

Description

Technical field [0001] The invention relates to the technical field of metal anticorrosion, in particular to a high corrosion resistance metal anticorrosion paint and a preparation method thereof. Background technique [0002] Metal materials are damaged by the surrounding medium, which is called metal corrosion. Rust of metal is the most common form of corrosion. During corrosion, a chemical or electrochemical heterogeneous reaction occurs on the interface of the metal, which turns the metal into an oxidation (ion) state. This will significantly reduce the strength, plasticity, toughness and other mechanical properties of metal materials, destroy the geometric shape of metal components, increase wear between parts, deteriorate electrical and optical physical properties, shorten the service life of the equipment, and even cause disasters such as fires and explosions. Sexual accidents. The economic loss caused by metal corrosion in the United States in 1975 was 70 billion U.S. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/00C09D161/20C09D163/02C09D5/10

CPCC09D163/00C08K2201/011C08L2205/03C09D5/106C09D7/61C09D7/63C09D7/65C08L61/20C08L77/00C08K13/02C08K2003/0893C08K3/04C08K5/098C08K5/54C08K3/28

Inventor 徐凯

Owner ZHANGJIAGANG FREE TRADE ZONE GUANXIANG TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com