Gas protecting welding wire with nano-coating

A gas-shielded welding wire and nano-coating technology, which is applied to welding media, electrical components, manufacturing tools, etc., can solve the problems of lack of high-current gas-shielded welding wire, pitting corrosion on the surface of the welding wire, and weakened weld performance. Good rust, good weld toughness, stable arc effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

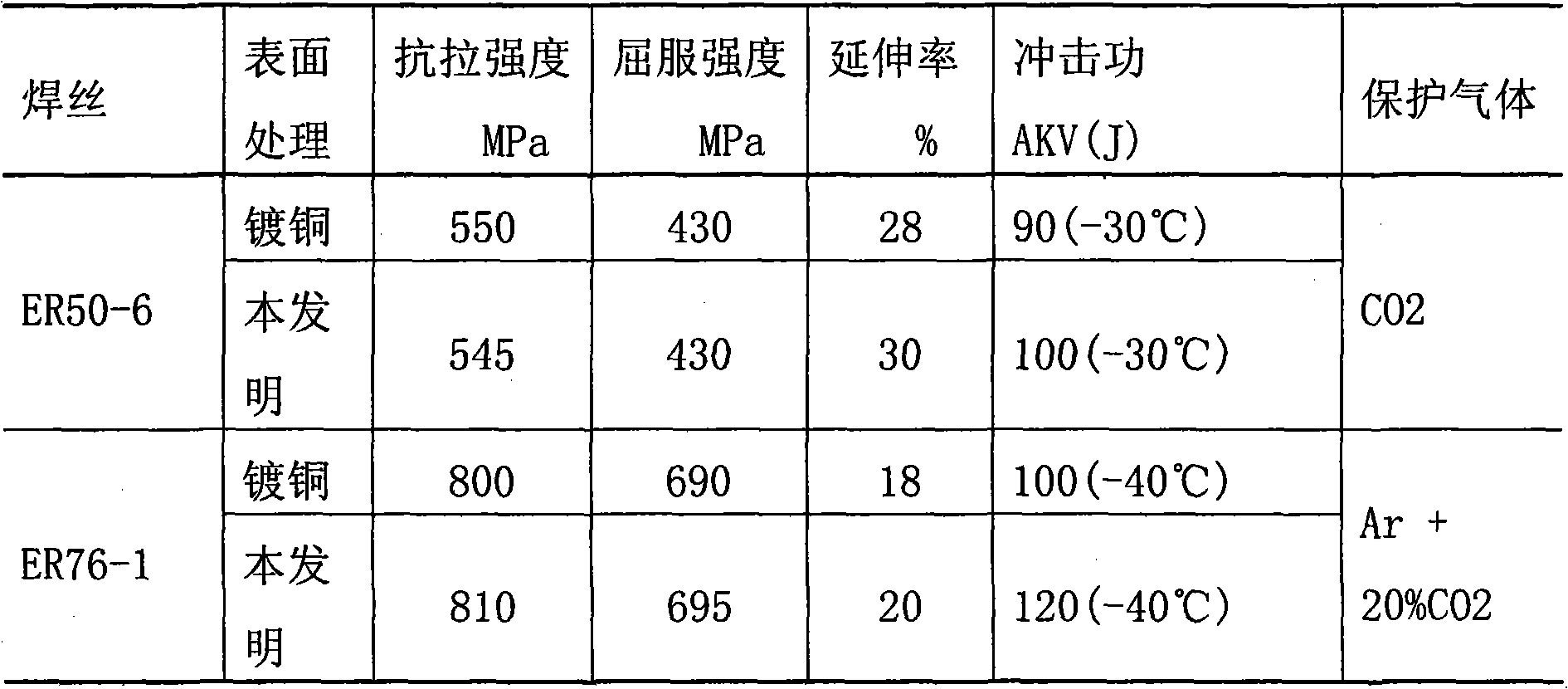

Examples

Embodiment Construction

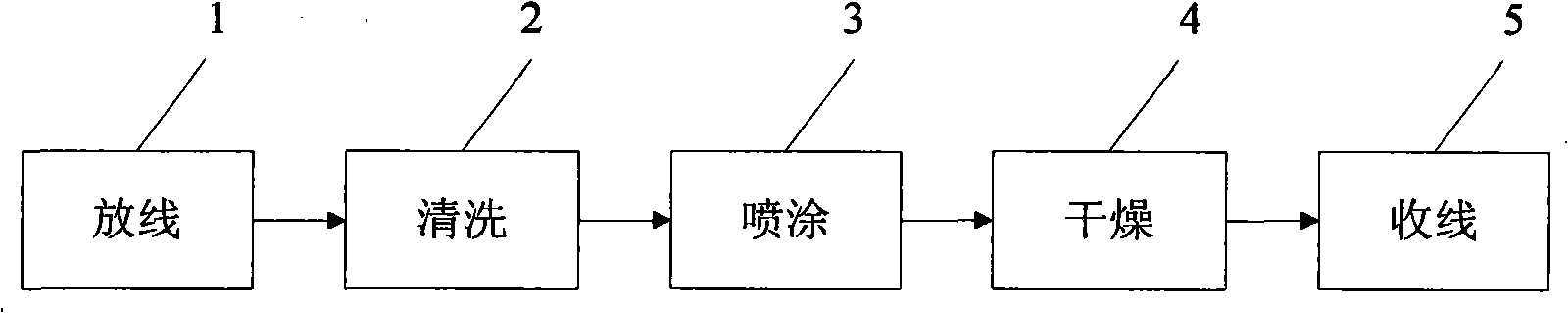

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] A gas-shielded welding wire with a nano-coating has a coating on its surface, and the composition and weight percentage of the coating are:

[0019] Potassium tetraborate 0.05~0.18%,

[0020] Calcium stearate 0.15~0.80%,

[0021] Titanium dioxide balance;

[0022] The coating thickness is 100-300nm.

[0023] Preferably, the above-mentioned coating is sprayed on the surface of the welding wire by a sol-gel method.

[0024] Preferably, the above-mentioned sol-gel method uses organic titanium alkoxide hydrolysis reaction to initiate polycondensation reaction, first generates nano TiO 2 Sol, sprayed on the surface of the welding wire, when further polycondensation reaction will form a gel, after drying to obtain nano-TiO 2 coating.

[0025] Preferably, the organic titanium alkoxide is ethyl titanate or butyl titanate.

[0026] Prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com