Preparation method of water dispersible nano copper cooling lubricant for cold rolling

A lubricant and nano-copper technology, applied in the field of lubricants, can solve the problems of loss of lubrication performance, high cost of oil-soluble lubricants, rancid emulsion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

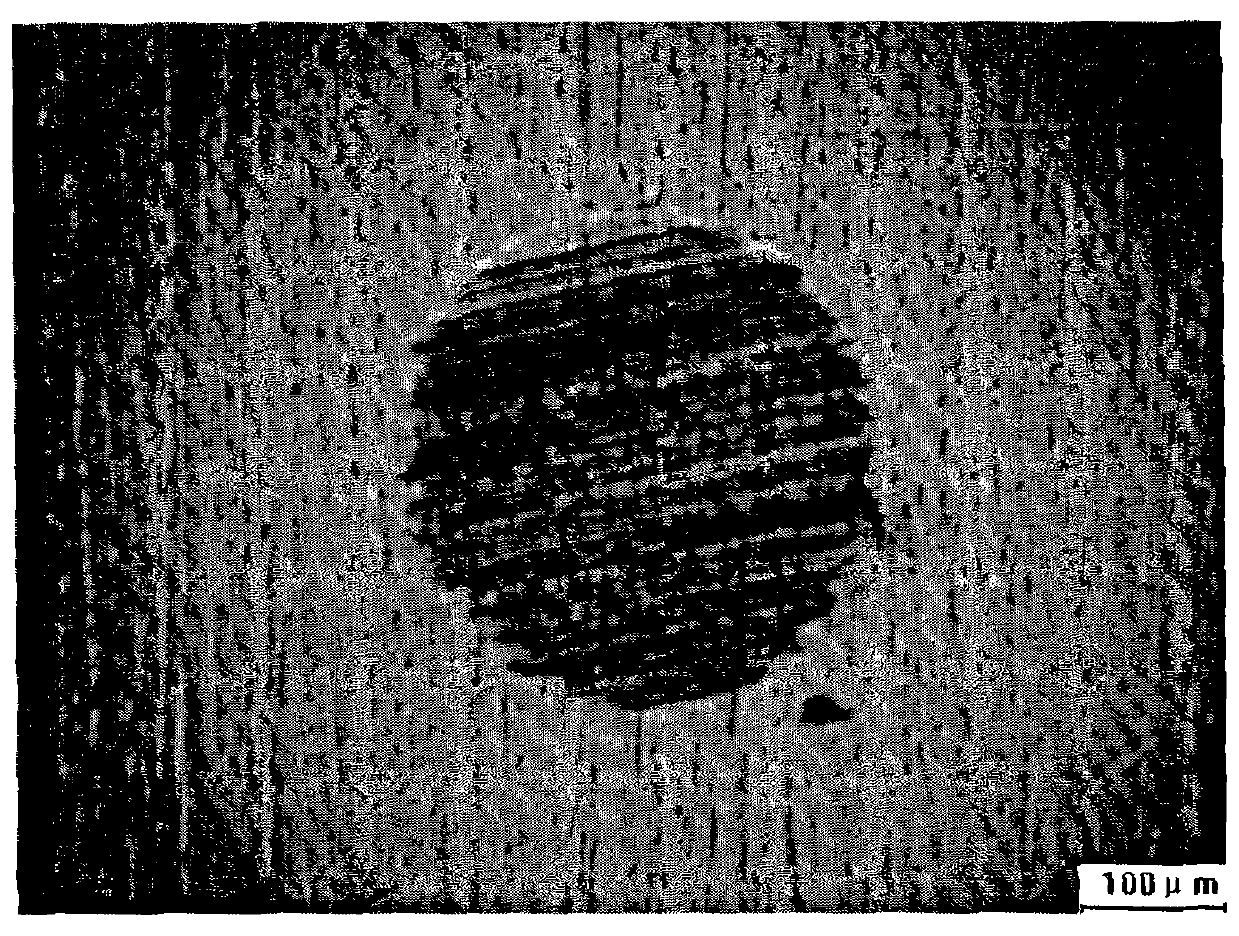

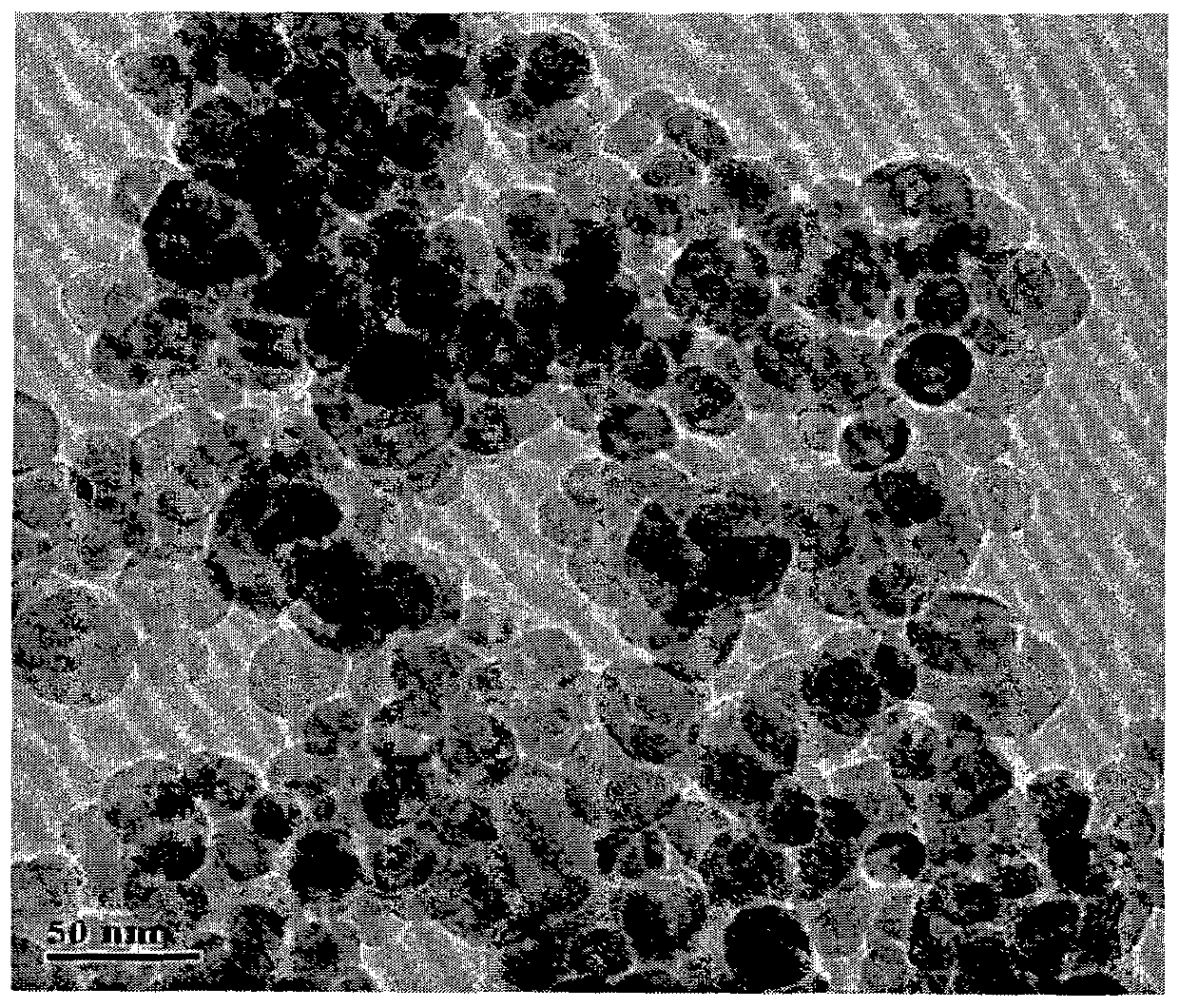

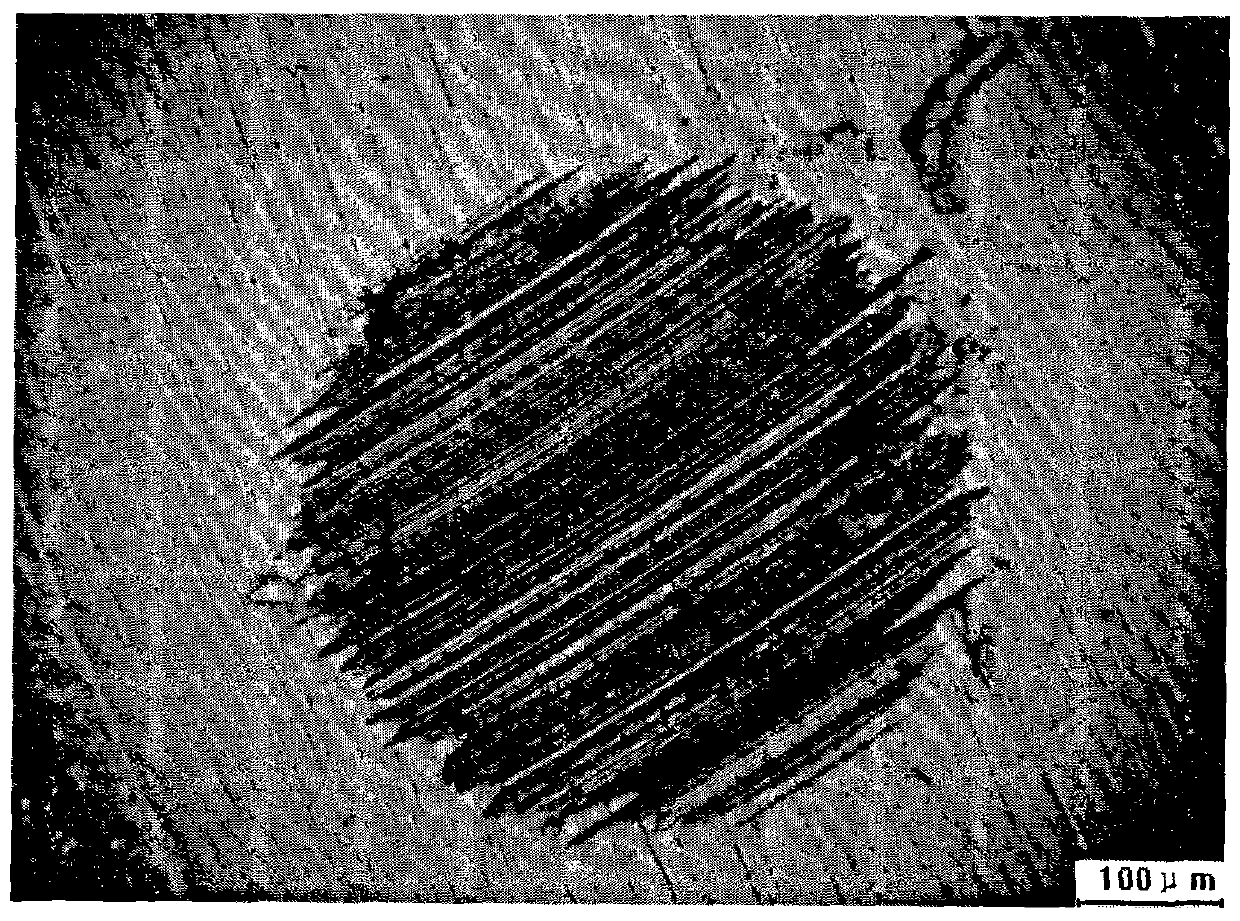

Image

Examples

preparation example Construction

[0034] A kind of preparation method of water-dispersed nano-copper cooling lubricant of the present invention comprises following preparation steps:

[0035] Step 1: Preparation of Surfactant

[0036] (A) in 10ml of absolute ethanol C 2 h 5 Add 7-12g of oleate into OH, and mix evenly to obtain the first mixed liquid;

[0037] The oleate can be sodium oleate C 17 h 33 COONa, potassium oleate C 17 h 33 COOK, barium oleate [(C 17 h 33 COO) 2 Ba], calcium oleate [(C 17 h 33 COO) 2 Ca];

[0038] (B) Add 1.5-4 g of alkali corresponding to oleate into 10 ml of deionized water, and mix evenly to obtain a second mixed solution;

[0039] Described alkali can be sodium hydroxide NaOH, potassium hydroxide KOH, barium hydroxide Ba(OH) 2 , calcium hydroxide Ca(OH) 2 ;

[0040] (C) After heating the second mixed solution to 60-80°C, add the first mixed solution; under the condition of stirring speed of 200-800r / min, continue to heat to 110-200°C, and at a temperature of 110-2...

Embodiment 1

[0056] Step 1: Preparation of Surfactant

[0057] (A) Add 9.4g of sodium oleate in 10ml of absolute ethanol, mix well to obtain the first mixed solution;

[0058] (B) Add 2g of sodium hydroxide to 10ml of deionized water, and mix evenly to obtain the second mixed solution;

[0059] (C) After heating the second mixed solution to 80°C, add the first mixed solution; under the condition of stirring speed of 600r / min, continue to heat to 150°C, and keep the temperature at 150°C for 5 years; Cool to 30°C under the conditions of 5°C / min and stirring speed of 1200r / min to prepare the surfactant;

[0060] Step 2: Preparation of Dispersant Solution

[0061] Add 2.1g of PEG-400 into 10ml of deionized water, mix well to obtain a dispersant solution;

[0062] In this embodiment, when the dispersant is selected from the dispersant solution prepared by any type of PEG, there is no difference in performance.

[0063] The third step: preparation of nano-copper cooling lubricant

[0064] (...

Embodiment 2

[0072] Step 1: Preparation of Surfactant

[0073] (A) Add 11.7g of Potassium Oleate in 10ml of absolute ethanol, mix well to obtain the first mixed solution;

[0074] (B) Add 4g of potassium hydroxide to 10ml of deionized water, mix well to obtain the second mixed solution;

[0075] (C) After heating the second mixed solution to 60°C, add the first mixed solution; continue heating to 200°C at a stirring speed of 200r / min, and keep the temperature at 200°C for 10min; then cool down at a rate of Cool to 25°C under the conditions of 8°C / min and a stirring speed of 1500r / min to prepare the surfactant;

[0076] Step 2: Preparation of Dispersant Solution

[0077] Add 3.7g of PVA-20000 into 10ml of deionized water, mix well to get a dispersant solution;

[0078] In this embodiment, when the dispersant is selected from the dispersant solution prepared by any type of PVA, there is no difference in performance.

[0079] The third step: preparation of nano-copper cooling lubricant

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com