Square light steel member with reinforcement parts

一种加强部件、轻钢构件的技术,应用在构件领域,达到有利于防锈蚀、增强抗弯矩和抗压力、增强抗压力及抗弯矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific features and effects of the square light steel member provided with reinforcing parts according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

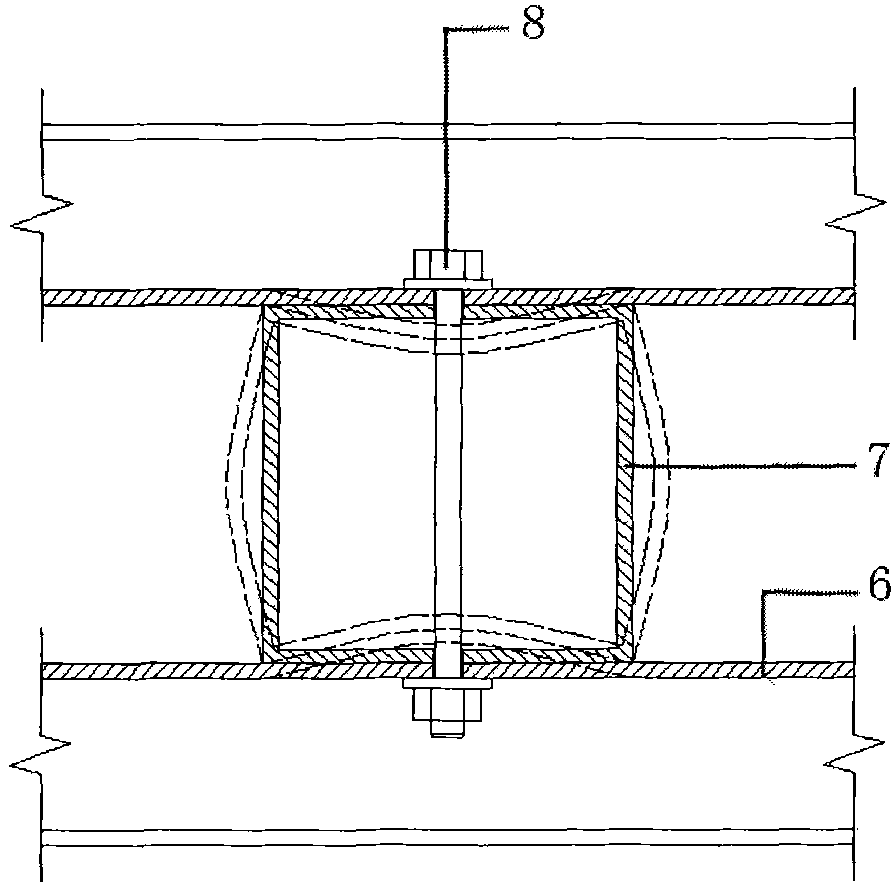

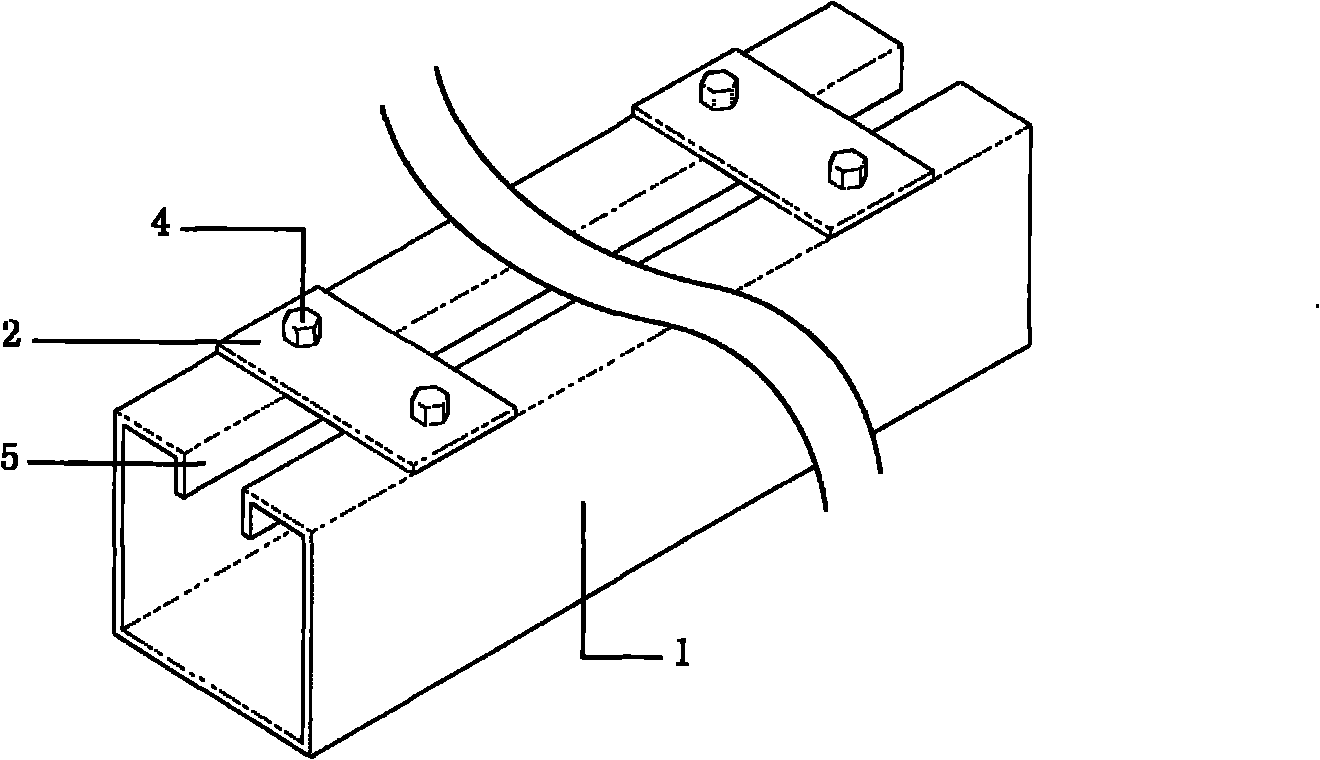

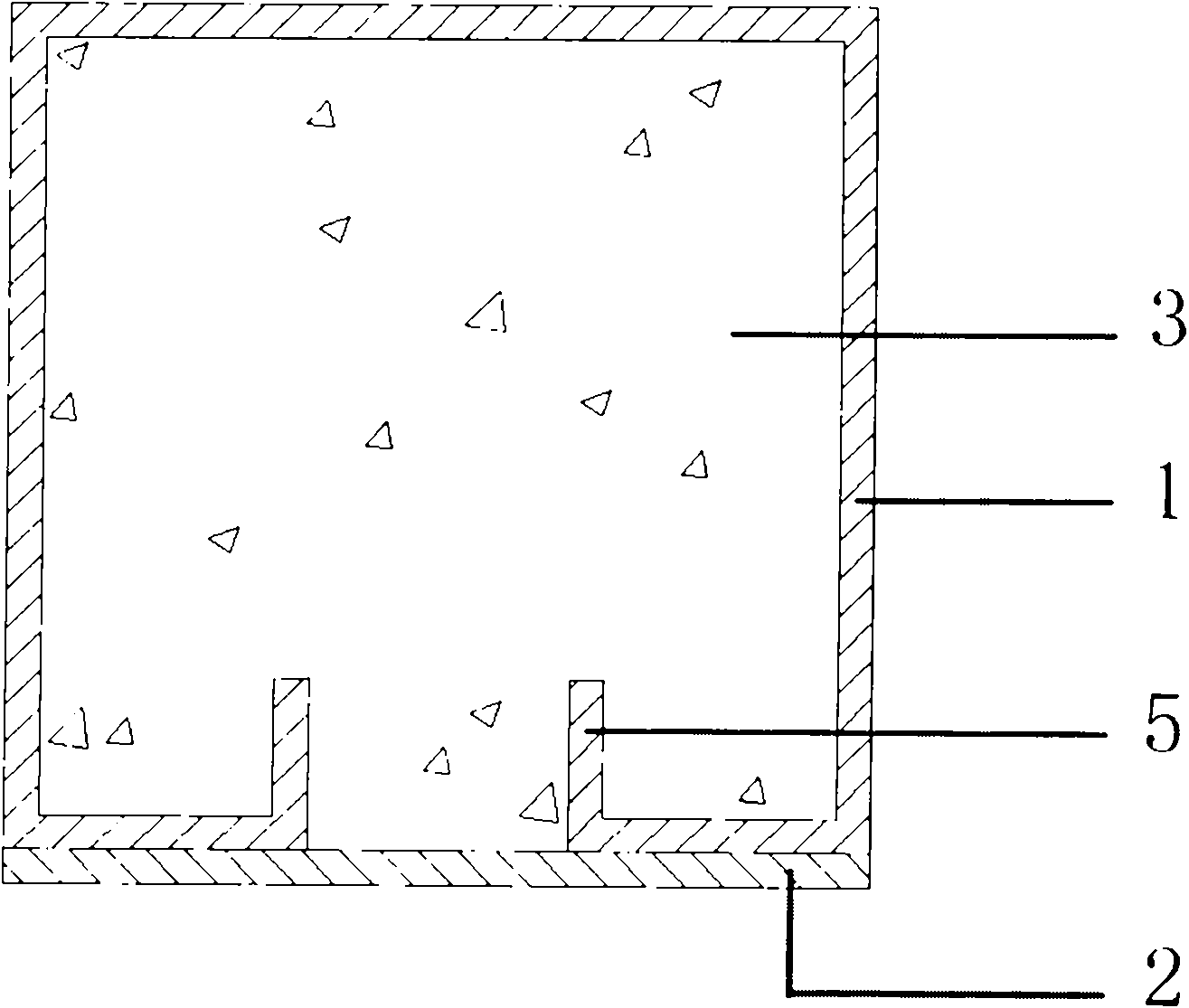

[0034] see figure 2 As shown, it is a square light steel member provided with reinforcing parts in a preferred embodiment of the present invention, which mainly includes a main body structure 1, which is a square steel pipe integrally formed by steel plates of a certain thickness, and one side of the square steel pipe is provided with Opening, the two sides of the opening are corner folds 5 respectively; and the reinforcing part 2, which is fixedly connected with the side of the main structure 1 provided with the opening by locking high tension bolts 4, and is arranged at a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com