Waterborne diamond wire silicon wafer cutting liquid

A silicon chip cutting fluid and diamond wire technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of difficult cleaning of solid silicon fine powder, etc., and achieve the effects of low equipment requirements, easy control of conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

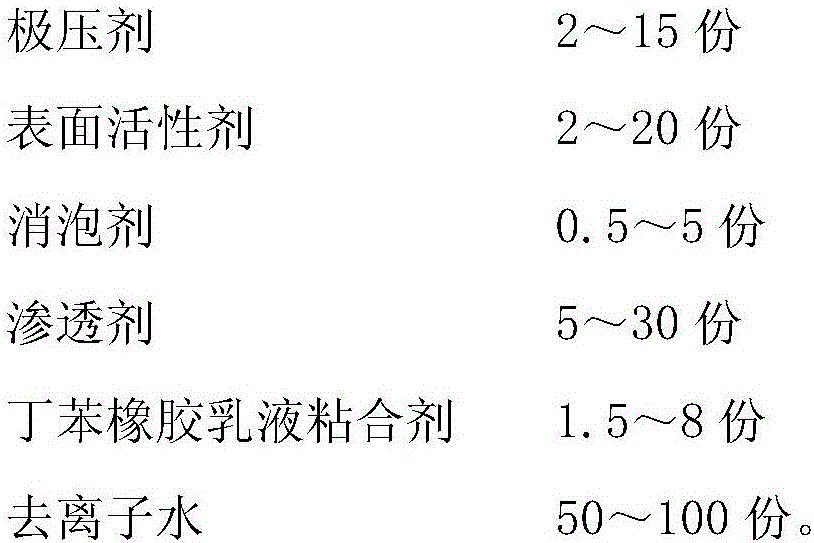

[0019] A water-based diamond wire silicon wafer cutting fluid, calculated in parts by weight as the following components:

[0020]

[0021] The above-mentioned surfactants are alcohol-based nonionic surfactants with the structure RO(C 3 H 6 O)a(CH 2 CH 2 O)b(C 3 H 6 O)cH,

[0022] Wherein, R is n-butyl, a=18, b=20, c=15;

[0023] The preparation method of the water-based diamond wire silicon wafer cutting fluid in this embodiment is as follows:

[0024] At room temperature (25°C), add the above-mentioned surfactants, penetrants, defoamers, styrene-butadiene rubber emulsion binders and extreme pressure agents to deionized water, and stir evenly to obtain water-based diamond wire silicon wafer cutting fluid.

Embodiment 2

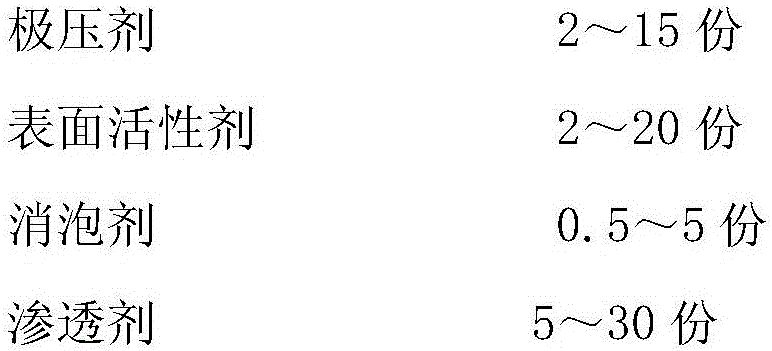

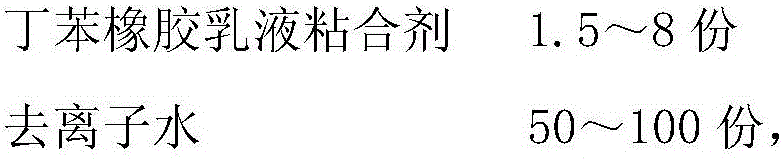

[0026] A water-based diamond wire silicon wafer cutting fluid, calculated in parts by weight as the following components:

[0027]

[0028] The above-mentioned surfactants are alcohol-based nonionic surfactants with the structure RO(C 3 H 6 O)a(CH 2 CH 2 O)b(C 3 H 6 O)cH,

[0029] Wherein, R is isobutyl, a=14, b=23, c=13;

[0030] The preparation method of the water-based diamond wire silicon wafer cutting fluid in this embodiment is as follows:

[0031] At room temperature, add the above-mentioned surfactants, penetrants, defoamers, styrene butadiene rubber emulsion binders and extreme pressure agents to deionized water, and stir evenly to obtain water-based diamond wire silicon wafer cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com