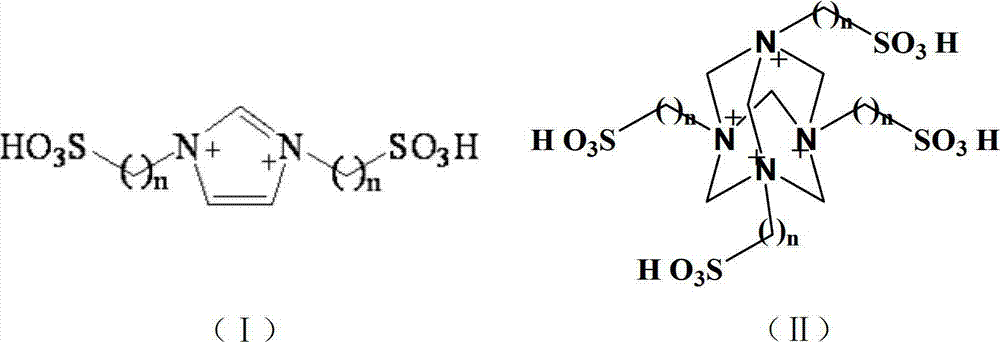

Aqueous environment-friendly cutting fluid synergized by functional ionic liquid and method for preparing same

An ionic liquid, cutting fluid technology, applied in the petroleum industry, lubricating composition, etc., to achieve the effects of excellent lubrication, easy separation and treatment, and less discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

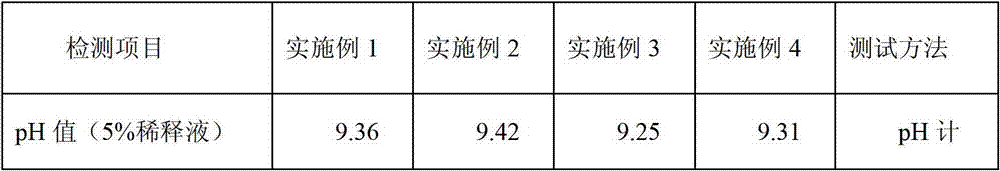

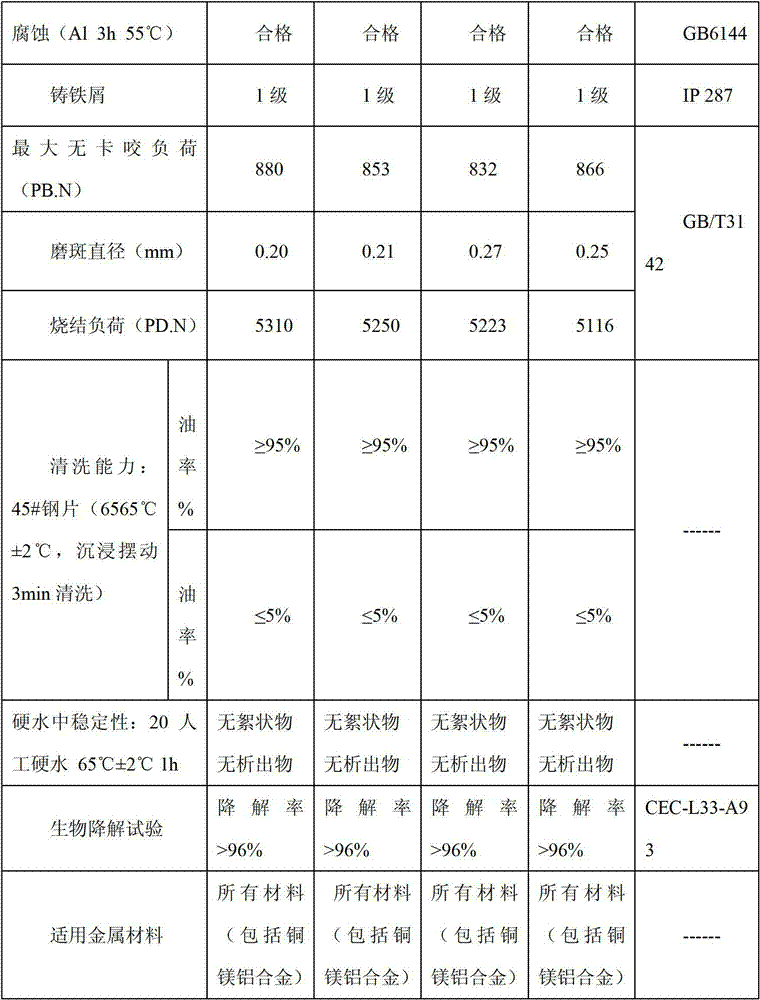

Examples

Embodiment 1

[0043] Epoxy 2-methylhexyl soyate: 45%

[0044] Triolein: 15%

[0045]Triethanolamine laureth sulfate: 15%

[0046] Triisopropanolamine: 10%

[0047] Tolyl benzotriazole: 1%

[0048] Corrguard SI: 0.5%

[0049] TROY K18N: 1%

[0050] [EAMIM] BF 4 : 1%

[0051] DIL: 0.5%

[0052] Trimeric acid: 1%

[0053] Water: 10%

[0054] According to the above materials and weight percentages, its preparation method and steps are:

[0055] a) Glycerin, oleic acid and tetrasulfonic acid hexamethylenetetramine bisulfate ionic liquid were added into the reactor at a material ratio of 1:4:0.05 and mixed, and stirred and reacted at 150° C. for 4 h. After the reaction, the liquid is automatically separated into layers, and the lower layer is separated for recycling to obtain the upper layer of triolein.

[0056] b) Stir and mix triglyceride, 2-methylhexyl soyate and TROY K18N uniformly at normal temperature and pressure to obtain the mixture component A;

[0057] c) Stir and m...

Embodiment 2

[0061] Trimethylolpropane Oleate: 60%

[0062] Triolein: 10%

[0063] Tall Oil Monoisopropanolamide: 10%

[0064] Monoisopropanolamine: 5%

[0065] Tolylbenzotriazole: 0.5%

[0066] Corrguard SI: 1%

[0067] TROY K18N: 1.5%

[0068] PehIL: 1%

[0069] Trimeric acid: 1%

[0070] Water: 10%

[0071] According to the above materials and weight percentages, its preparation method and steps are:

[0072] a) Glycerin, oleic acid and bis-imidazolium p-toluenesulfonate ionic liquid were added into the reactor at a material ratio of 1:3:0.001 and mixed, and stirred and reacted at 130°C for 1 h. After the reaction, the liquid is automatically separated into layers, and the lower layer is separated for recycling to obtain the upper layer of triolein.

[0073] b) Stir and mix glycerin trioleate, trimethylolpropane oleate and TROY K18N at normal temperature and pressure to obtain the mixture component A;

[0074] c) Stir and mix monoisopropanolamine, trimer acid and water at 30°C...

Embodiment 3

[0078] Isooctyl oleate: 46%

[0079] Triolein: 11%

[0080] Fatty acid amide polyoxyethylene ether: 12%

[0081] Diisopropanolamine: 15%

[0082] Tolylbenzotriazole: 0.5%

[0083] Corrguard SI: 0.5%

[0084] TROY K18N: 1%

[0085] PehIL: 1%

[0086] DIL: 1%

[0087] Trimeric acid: 2%

[0088] Water: 10%

[0089] According to the above materials and weight percentages, its preparation method and steps are:

[0090] a) Glycerin, oleic acid and bis-sulfoimidazolium trifluoroacetate ionic liquid were added into the reaction kettle at a material ratio of 1:5:0.2 and mixed, and stirred and reacted at 160° C. for 5 h. After the reaction, the liquid is automatically separated into layers, and the lower layer is separated for recycling to obtain the upper layer of triolein.

[0091] b) Stir and mix triglyceride, isooctyl oleate and TROY K18N evenly at normal temperature and pressure to obtain the mixture component A;

[0092] c) Stir and mix diisopropanolamine, trimer acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com